Exploring the World of 3D Printers: A Comprehensive Guide

In recent years, 3D printing has undergone a revolutionary transformation, evolving from a novelty technology into a powerful tool impacting industries, hobbies, and education. As the technology advances, more people are starting to explore the fascinating world of 3D printing. In this comprehensive guide, we will delve into the various types of 3D printers, their applications, and what you need to know if you’re considering venturing into this exciting domain.

What is 3D Printing?

At its core, 3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from a digital file. This is achieved through the gradual addition of material layer by layer. Unlike traditional subtractive manufacturing methods, which cut away material to create parts, 3D printing builds objects directly from a CAD (Computer-Aided Design) model, enabling the creation of complex shapes and designs that would otherwise be impossible to produce.

Types of 3D Printers

When exploring 3D printers, it’s essential to understand the different types available in the market. Each type has its advantages and applications. The most common are:

1. Fused Deposition Modeling (FDM)

FDM is the most widely used 3D printing technology, especially among hobbyists. It works by melting a thermoplastic filament and extruding it through a heated nozzle. The printer lays down each layer upon the previous one until the object is completed. FDM printers are often affordable, user-friendly, and suitable for a wide range of materials, including ABS and PLA.

2. Stereolithography (SLA)

SLA is a resin-based technology that utilizes a laser to cure liquid resin into solid objects. The laser traces the object’s shape on the surface of the resin, which hardens upon exposure. This process continues layer by layer. SLA printers are known for their impressive detail and smooth surface finish, making them ideal for applications such as jewelry, dental models, and prototypes.

3. Selective Laser Sintering (SLS)

SLS is another powdered material-based technology, but instead of resin, it uses nylon or other thermoplastics. A laser selectively fuses powdered material into solid form. SLS is particularly favored for creating complex geometries and functional parts, making it popular in the aerospace and automotive industries.

4. Digital Light Processing (DLP)

Similar to SLA, DLP uses light to cure resin, but instead of a laser, it employs a digital light projector. This allows for quicker printing times since it can cure an entire layer at once. DLP is well-regarded for high-resolution prints, especially in fields that require intricate details, like miniatures and prototypes.

5. Multi Jet Fusion (MJF)

MJF uses a technique that combines both inkjet and thermal processes to create fully finished parts. It deposits a binding agent onto the powder material and then applies heat to fuse the particles together. MJF is excellent for producing strong, functional plastic parts at a rapid pace, catering to both prototyping and low-volume production.

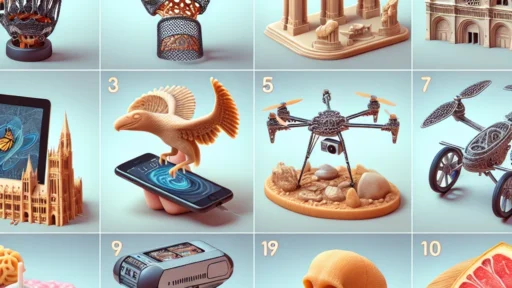

Applications of 3D Printing

The versatility of 3D printing opens up countless possibilities across various fields. Here are some notable applications:

1. Prototyping

One of the most significant advantages of 3D printing is rapid prototyping. Designers and engineers can create prototypes quickly, test them within a short timeframe, and iterate designs without the lengthy production processes of traditional manufacturing.

2. Medical

In the medical field, 3D printing is revolutionizing how prosthetics, dental implants, and even organ models are produced. Customizable solutions can be tailored to the patient’s specific needs, enhancing comfort and efficacy.

3. Aerospace and Automotive

Companies in these industries are using 3D printing for lightweight, complex components that reduce weight and improve fuel efficiency. The ability to create parts on-demand also significantly decreases lead times in production.

4. Education

3D printing is increasingly being integrated into educational settings, providing students with hands-on experiences in engineering, design, and art. It enhances creative thinking and problem-solving skills, preparing them for future careers in technology.

Getting Started with 3D Printing

If you’re interested in delving into 3D printing, here are some tips to help you get started:

-

Choose the Right Printer: Select a printer that fits your budget and purpose. If you’re a beginner, an FDM printer is a great starting point due to its affordability and ease of use.

-

Learn CAD Software: Familiarize yourself with CAD software for creating 3D models. Programs like TinkerCAD and Fusion 360 are user-friendly and great for beginners.

-

Join a Community: There are numerous online forums and local maker spaces where you can learn from experienced users, share ideas, and get assistance with your projects.

-

Experiment: Start small with simple designs and gradually work your way up to more complex projects as you gain confidence and experience.

Conclusion

The world of 3D printing is vast, offering endless possibilities for creativity, innovation, and problem-solving. Whether you’re interested in hobbyist projects, professional applications, or educational endeavors, understanding the technology and its potential can open up new horizons for you. As this technology continues to evolve, the future looks bright for 3D printing, and there’s no better time to get involved. Happy printing!