Exploring the Range of 3D Filaments: From PLA to ABS

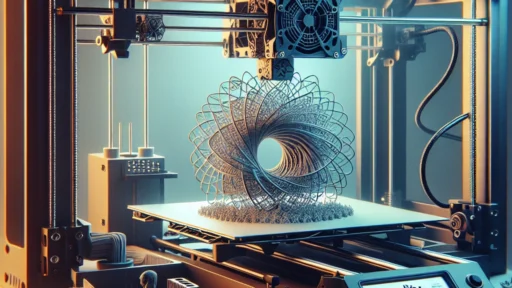

3D printing has revolutionized the manufacturing and prototyping world, providing enthusiasts and industries alike with unprecedented flexibility and creative freedom. At the core of this technology lies a crucial component: 3D filaments. Understanding the different types of filaments available is essential for achieving optimal results in your projects. In this post, we will explore the range of 3D filaments, focusing on two of the most commonly used materials: PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene).

What Are 3D Filaments?

3D filaments are materials used in fused deposition modeling (FDM), one of the most widely used 3D printing methods. In FDM printing, the filament is heated until it melts, allowing it to be extruded layer by layer to build a three-dimensional object. The choice of filament significantly affects the quality, strength, and durability of the printed object.

Introduction to PLA Filament

Advantages of PLA

PLA, or Polylactic Acid, is derived from renewable resources such as corn starch or sugarcane, making it one of the most eco-friendly filaments available. Here are some of its notable advantages:

-

Ease of Use: PLA is known for its user-friendly nature, making it ideal for beginners. It adheres well to the print bed, reduces warping, and doesn’t require a heated bed for printing.

-

Print Quality: PLA generally provides excellent print quality and can produce fine details due to its lower shrinkage rates. This is particularly advantageous for intricate designs and artistic projects.

-

Biodegradability: One of the standout features of PLA is its biodegradability. While it takes industrial composting conditions to break down efficiently, it is still a safer option compared to traditional petroleum-based plastics.

Disadvantages of PLA

Despite its numerous benefits, PLA does have some drawbacks:

-

Lower Heat Resistance: PLA is not ideal for high-temperature environments. It can deform at temperatures above 60°C, making it unsuitable for functional parts exposed to heat.

-

Brittleness: PLA is relatively brittle compared to other filaments, meaning parts can break or snap under stress. This makes it less suited for items requiring robustness and flexibility.

Introduction to ABS Filament

Advantages of ABS

On the other hand, ABS (Acrylonitrile Butadiene Styrene) is a petroleum-based thermoplastic known for its durability and strength. Here are some of its advantages:

-

High Strength: ABS is known for its superior strength and impact resistance, making it suitable for functional and mechanical parts. It is commonly used in industrial applications and product prototypes.

-

Heat Resistance: Unlike PLA, ABS can withstand higher temperatures (up to 100°C), making it ideal for items exposed to heat, such as automotive parts.

-

Post-Processing Capabilities: ABS can be smoothed effectively using acetone vapor, providing a polished finish for printed items. This feature is great for aesthetic projects or functional prototypes where the look matters.

Disadvantages of ABS

However, ABS is not without its challenges:

-

Warping Issues: ABS can warp during the cooling process, leading to misaligned prints. A heated bed and controlled cooling environments are often necessary to mitigate this issue.

-

Odor: The printing process for ABS emits fumes that some may find unpleasant, requiring good ventilation during printing.

Other Filament Materials to Consider

While PLA and ABS are highly popular, the world of 3D filaments boasts a variety of other materials worth exploring:

-

PETG: Polyethylene Terephthalate Glycol-modified is a strong and flexible filament that combines the best of both PLA and ABS. It is resistant to moisture and can handle higher temperatures.

-

TPU: Thermoplastic Polyurethane is a flexible filament that is ideal for creating rubber-like parts, such as phone cases and wearable items.

-

Nylon: Known for its exceptional durability and flexibility, nylon is suited for heavy-use applications but often requires more advanced printing techniques.

Conclusion

Choosing the right filament for your 3D printing project is paramount to achieving the desired results. PLA continues to reign as the go-to option for beginners due to its ease of use and environmental friendliness. In contrast, ABS offers rugged durability for more demanding applications. Knowing the properties and benefits of each filament will empower you to make informed decisions and achieve stunning results in your 3D printing endeavors. So, whether you are making prototypes, decorative items, or functional parts, understanding the diverse range of 3D filaments can enhance your creative journey and broaden your manufacturing capabilities. Happy printing!