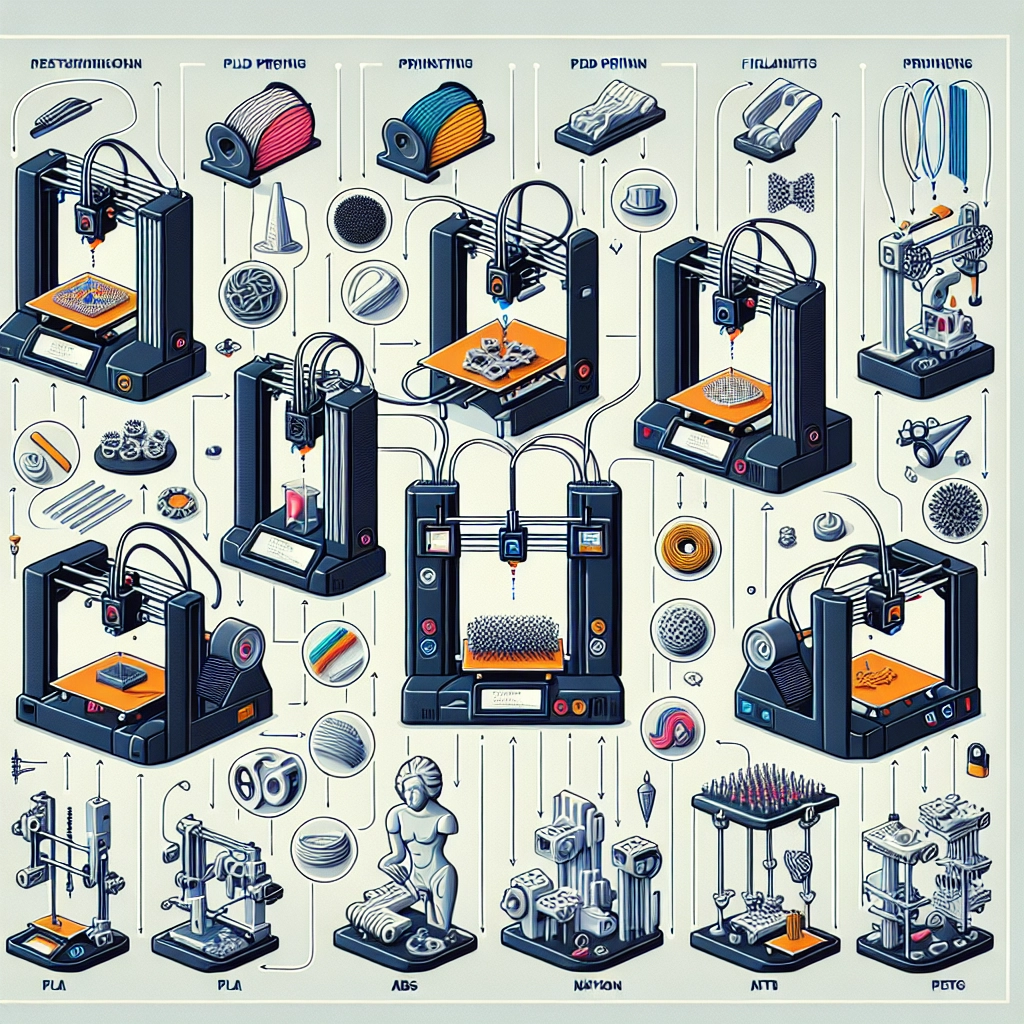

The Best Practices for 3D Printing with Different Filaments

3D printing has revolutionized the way we approach manufacturing, prototyping, and even hobby crafts. With a plethora of materials available on the market, each filament type offers its own unique properties, advantages, and challenges. Understanding the best practices for working with different filaments can significantly improve your print quality and efficiency. This blog post will explore the best practices for three popular filament types: PLA, ABS, and PETG.

1. PLA (Polylactic Acid)

Overview

PLA, derived from renewable resources like corn starch, is one of the most widely used 3D printing filaments. Its ease of use and low cost make it a favorite among beginners.

Best Practices

-

Temperature Settings: PLA typically prints well at temperatures ranging from 180°C to 220°C. Start at a lower temperature and gradually increase to find the optimal setting for your specific printer and filament.

-

Bed Adhesion: Use blue painter’s tape, a glue stick, or a PEI sheet to enhance bed adhesion. A heated bed is not always necessary, but if you have one, set it between 50°C and 60°C.

-

Cooling: Effective cooling is essential for PLA. Use a fan or cooling duct to ensure that each layer solidifies quickly, resulting in sharper details and reducing warping.

-

Storage: PLA is hygroscopic, meaning it absorbs moisture from the air, which can affect print quality. Store PLA in a cool, dry place or vacuum-sealed bags.

2. ABS (Acrylonitrile Butadiene Styrene)

Overview

ABS is a strong, durable plastic commonly used for functional parts, toys, and automotive components. Its resilience and higher temperature resistance are great for parts that experience stress.

Best Practices

-

Temperature Settings: When printing ABS, the recommended nozzle temperature ranges from 220°C to 260°C. Again, start at a lower temperature and adjust as needed.

-

Heated Bed: A heated bed is crucial for ABS to prevent warping. Set your heated bed to 100°C–110°C for optimal adhesion.

-

Enclosure: ABS is prone to warping or cracking, especially if there are rapid temperature shifts. Using a printer enclosure helps maintain a consistent temperature during printing and reduces drafts.

-

Post-Processing: For a smooth finish, consider using acetone vapor to smooth out the surfaces of ABS prints. However, be cautious with ventilation and safety.

-

Ventilation: Always ensure proper ventilation when printing with ABS, as it can emit harmful fumes. Use an air filtration system or print in a well-ventilated area.

3. PETG (Polyethylene Terephthalate Glycol-modified)

Overview

PETG combines the ease of printing associated with PLA and the durability of ABS, making it an excellent option for both beginners and experienced users. It possesses good mechanical properties and is resistant to moisture.

Best Practices

-

Temperature Settings: PETG typically prints well at a temperature range of 220°C to 250°C. Like other filaments, testing different temperatures can help find the ideal range for your printer.

-

Bed Adhesion: PETG adheres well to most surfaces, but using a heated bed set to around 70°C can enhance adhesion and minimize the risk of warping. A light coating of glue stick can also help.

-

Cooling: Unlike PLA, PETG can benefit from moderate cooling. A fan speed between 30-50% can lead to better layer adhesion and reduce stringing.

-

Stringing and Oozing: Adjust retraction settings to minimize stringing, a common problem with PETG. Increasing retraction distance and speed can significantly improve the quality of prints.

-

Storage: PETG is less hygroscopic than PLA but should still be stored in dry conditions. Using desiccant packets can help absorb any moisture.

Conclusion

Understanding the distinct properties and best practices for various 3D printing filaments is essential for achieving high-quality prints. Whether you’re working with PLA, ABS, or PETG, consider temperature settings, bed adhesion, cooling requirements, and proper storage habits to improve your 3D printing experience. With this knowledge in hand, you’ll be well-equipped to tackle your printing projects with confidence and success. Happy printing!