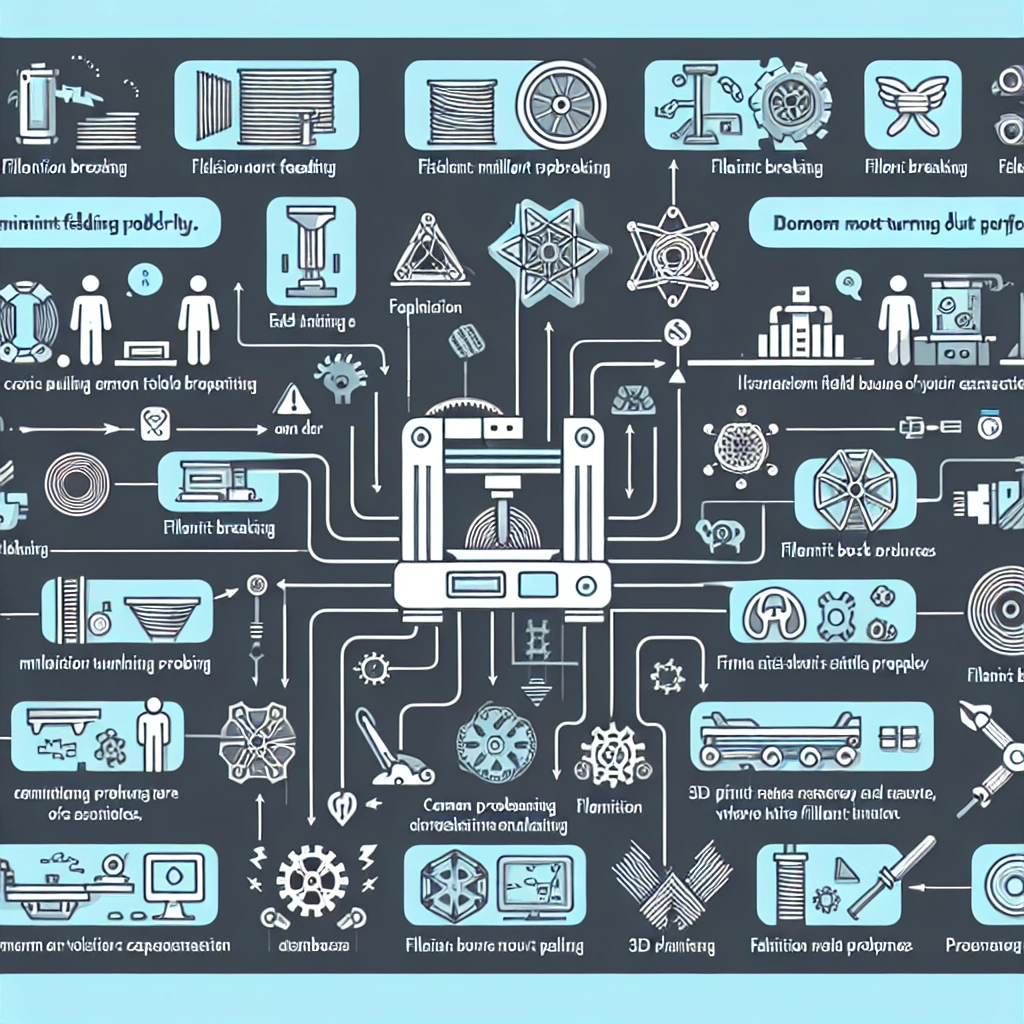

Troubleshooting Filament Issues While 3D Printing

Ah, the magic of 3D printing! There’s just something incredibly satisfying about watching your digital designs come to life right before your eyes. But let’s be real: as much as we love our 3D printers, they can be temperamental little beasts. One of the most common sources of frustration? Filament issues. Whether you’re a seasoned maker or just dipping your toes into the world of 3D printing, knowing how to troubleshoot filament-related problems can save you a lot of headaches—and filament!

Spotting the Signs

Before we dive into solutions, let’s familiarize ourselves with the common signs of filament issues. The first signs can often be found right at the extruder or the print head. Do you notice uneven layers, inconsistent extrusion, or perhaps some clogs? These could be indicators that your filament is misbehaving.

Another thing to watch out for is the finished print. If you’re seeing stringing, blobs, or layer separation in your print, your filament is probably the culprit. But don’t fret; most of these issues can be fixed with a bit of tinkering.

1. Moisture in the Filament

One of the biggest enemies of filament is moisture. If your filament has absorbed moisture, it can lead to bubbling, hissing sounds during printing, and poor layer adhesion.

Solution: The best fix here is to dry out your filament. You can use a food dehydrator, an oven set to a very low temperature, or even buy a filament dryer from specialty 3D printing shops. Ideally, keep your filament in airtight containers with desiccants to avoid future moisture issues.

2. Filament Diameter Issues

Another frequent issue arises from the filament’s diameter. If your printer is set for a 1.75 mm filament but you’re using 3 mm filament (or vice versa), it’s going to be a rough ride.

Solution: Always double-check the filament diameter your printer is set up for. If you’ve switched filament types, update the settings in your slicer to correspond with the new filament.

3. Clogs and Jams

Clogs in the nozzle can lead to all sorts of mischief, from inconsistent extrusion to complete filament failure. A clogged nozzle can be caused by burnt filament residue or incompatible materials getting stuck.

Solution: If you suspect a clog, start by cleaning the nozzle. Heat it to printing temperature and use a small needle or a nozzle cleaning tool to clear out remnants. If it’s particularly bad, you may need to perform a cold pull with a nylon filament to help dislodge the clog.

4. Temperature Control

The right temperature can make or break your print. Too hot, and the filament may string or droop; too cold, and you might get under-extrusion. Each filament type has a recommended temperature range.

Solution: Always check the manufacturer’s guidelines for the optimal printing temperature. If you’re experimenting with different filaments or settings, consider printing temperature towers to find the sweet spot!

5. Poor Extrusion Speed

If your printer is moving too fast while trying to extrude filament, it may not be able to keep up, leading to under-extrusion or gaps in your layers.

Solution: Slow down the print speed and reduce the flow rate in your slicing software. Sometimes, a minor tweak can lead to major improvements.

6. Filament Quality

Let’s be honest: not all filaments are created equal. Low-quality or expired filament can lead to inconsistent prints and frequent failures.

Solution: When purchasing filament, invest in reputable brands. Check reviews and forums to see what others have experienced. And remember, even if you bought it at a discount, you’ll pay for it with more time spent troubleshooting.

7. Insufficient Bed Adhesion

Lastly, if your print isn’t adhering to the bed, it can cause problems later on in the printing process. This might not be a direct filament issue, but it certainly is a symptom that can point to problems.

Solution: Ensure your bed is clean, level, and properly heated. Using adhesives like glue stick or painter’s tape can also improve adhesion.

3D printing can indeed be an uphill battle at times, especially when filament issues rear their ugly heads. But armed with a little knowledge and troubleshooting strategies, you can often turn what could have been a disaster into a learning experience. The journey of discovering and mastering your machine might just lead to some of your best creations yet! Keep experimenting, and happy printing!