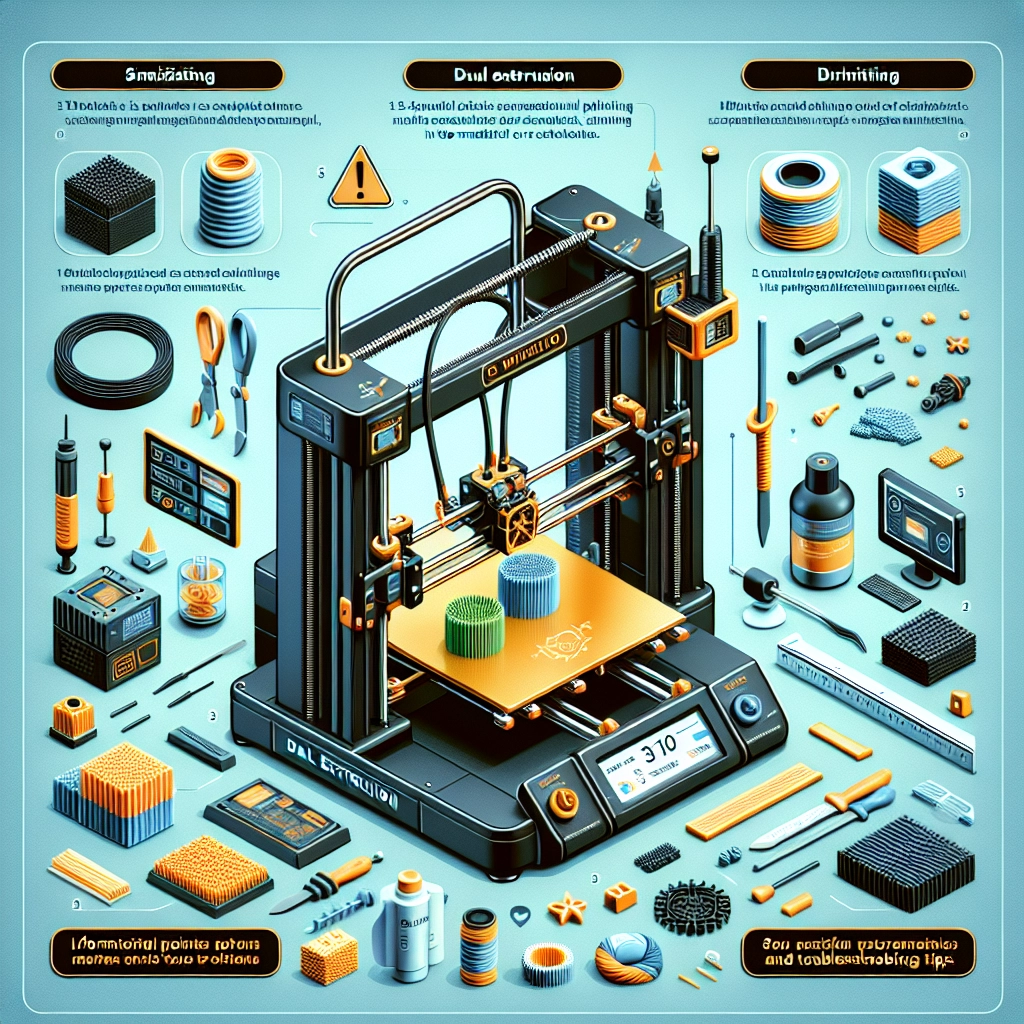

Utilizing Dual Extrusion in 3D Printing: A Complete Guide

3D printing technology has revolutionized the way we manufacture parts, prototypes, and models, allowing intricate designs to come to life with incredible detail. Among the various 3D printing techniques available, dual extrusion stands out as a powerful tool for creators looking to push the boundaries of their prints. If you’ve ever wanted to enhance your projects with multiple colors, materials, or functionalities, dual extrusion can be a game-changer. Let’s dive into what it is, how it works, and tips to maximize its potential.

What is Dual Extrusion?

Dual extrusion is a 3D printing technique that uses two separate extruders to print with two different materials or colors simultaneously. This capability opens up a world of opportunities, from creating visually stunning prints to enhancing functionality by combining flexible and rigid materials.

Imagine printing a model that not only boasts vibrant colors but also has certain sections that are more flexible for movement while others remain solid. This method allows for the creation of complex geometries that would otherwise be challenging with single extrusion systems.

The Mechanics Behind Dual Extrusion

The basic principle of dual extrusion involves two print heads—each with its own filament. While one extruder is laying down the first material, the second one can load a different filament, allowing for simultaneous printing.

-

Materials: One of the biggest advantages is the ability to use different types of filaments, such as PLA, ABS, PETG, or even specialty filaments like PVA (which is water-soluble) that work wonderfully for support structures.

-

Extruder Setup: The hardware typically consists of two separate nozzles, either mounted side-by-side or arranged in a particular orientation to allow for efficient movement. Some printers use a dual-geared extruder, while others may employ a Bowden setup.

-

Slicing Software: To take full advantage of dual extrusion, you’ll need slicing software (like Cura, PrusaSlicer, or Simplify3D) that supports multi-material printing. This software allows you to assign different filaments to various parts of your model for a seamless print process.

Tips for Successful Dual Extrusion Printing

Now that we’ve covered the basics, here are some tips to help you get the best results from your dual extrusion setup:

1. Choose Complementary Materials

Not all materials work well together when it comes to dual extrusion. For instance, if you plan to use PVA for supports, check compatibility with your primary filament. Ideally, choose materials that have similar melting temperatures to avoid printing issues.

2. Tuning Your Printer

Dual extrusion often requires fine-tuning. Adjusting settings such as retraction distance, speed, and temperature is crucial. For instance, you might need to increase retraction to prevent oozing from the idle nozzle. A little experimentation can go a long way.

3. Use a Brim or Raft

When printing with two different materials, having a brim or raft can help improve adhesion and prevent warping. This is especially useful if one material is prone to curling.

4. Adjust Z-Axis Offset

Sometimes, using two different filaments can result in slight height discrepancies. Ensure that your Z-axis is calibrated properly so that both nozzles extrude from the same height—this helps avoid layer misalignment.

5. Test Prints

Before diving into a larger project, conduct smaller test prints to tweak settings. This is a fantastic way to see how your materials interact and to make adjustments without wasting time and filament.

Practical Applications of Dual Extrusion

The versatility of dual extrusion expands far beyond simply mixing colors. Here are a few practical applications to inspire your next project:

- Functional Prototypes: Combine rigid and flexible materials for prototypes that actually mimic their intended use.

- Support Structures: Use water-soluble support like PVA to create complex geometries that easily dissolve post-printing.

- Artistic Creations: Imagine a sculpture that not only captures attention with vibrant colors but also incorporates textures and transparency.

The Bottom Line

Dual extrusion in 3D printing can significantly expand your creative horizons, allowing for designs that are not only visually stunning but also functionally diverse. While the learning curve might be steeper than with single extrusion, the rewards can be immense. With a little practice and experimentation, you can master the art of dual extrusion and elevate your 3D prints to a whole new level. Whether you’re an artist, engineer, or hobbyist, this technique can transform your ideas into tangible creations that amaze and inspire. Let your imagination run wild and see where dual extrusion can take you!