The Science Behind 3D Printing: Materials and Machinery Explained

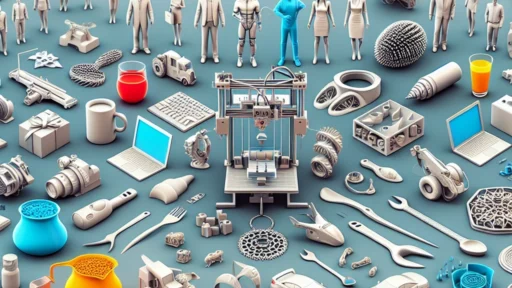

Ah, 3D printing! It’s like having a personal wizard that can conjure up almost anything out of thin air—well, almost. While it may seem like a magical process, there’s a whole world of science, materials, and machinery at play beneath the surface. Whether you’re a curious newbie or have some experience under your belt, let’s dive into the fascinating realm of 3D printing and explore what makes it tick!

The Basics of 3D Printing

At its core, 3D printing is an additive manufacturing process. Unlike traditional subtractive methods, where material is removed to create an object (think cutting, drilling, or milling), 3D printing builds objects layer by layer from a digital design. It’s a bit like icing a cake—a continuous process of adding material until you have a deliciously complete creation!

The journey usually begins with a 3D model, which can be created using computer-aided design (CAD) software or downloaded from online repositories. This model is sliced into thousands of layers, which guide the printer in producing the object layer by layer.

Common 3D Printing Technologies

There are several 3D printing technologies, each using different techniques and materials. Here are a few of the most popular ones:

Fused Deposition Modeling (FDM)

FDM is one of the most commonly used methods, particularly popular with hobbyists. This technique involves feeding a thermoplastic filament into a heated nozzle, which melts the plastic and deposits it onto a build platform. As each layer cools, it solidifies and bonds to the previous one.

One of the best things about FDM is the variety of materials you can use. From PLA (polylactic acid)—a biodegradable filament made from cornstarch—to ABS (acrylonitrile butadiene styrene), which is durable and impact-resistant, the choices are vast.

Stereolithography (SLA)

SLA takes a different approach by employing resin as a printing material. In this method, a UV light source cures liquid resin layer by layer to create an object. This results in high-resolution prints that are particularly well-suited for intricate designs and prototypes. However, the downside is that resin can be more expensive, and the cleanup requires some careful handling.

Selective Laser Sintering (SLS)

For more advanced users, SLS utilizes a laser to fuse powdered materials, such as nylon or metal, into solid objects. This method is known for its impressive mechanical properties and allows for complex geometries without the need for support structures. It’s often used in industries like aerospace and automotive due to its durability and strength.

Materials Matter

The choice of materials in 3D printing can significantly affect the final product’s appearance, strength, and functionality. Alongside the popular options already mentioned, there are countless materials to choose from, each tailored for specific applications. Some noteworthy ones include:

- TPU (Thermoplastic Polyurethane): A flexible material perfect for creating soft, rubber-like parts or items that require elasticity.

- PETG (Polyethylene Terephthalate Glycol): A trendy thermoplastic that is resistant to impact and moisture, making it great for everyday objects.

- Metal: Yes, you read that right! Advanced 3D printing technologies can process metal powders to manufacture robust industrial parts. Think of it as crafting metal like clay.

The Machinery Behind 3D Printing

To harness these materials, you need the right machinery. 3D printers come in various shapes and sizes, ranging from compact desktop devices to large industrial machines. The features of these printers can differ dramatically based on technology and intended use.

For instance, home 3D printers are mostly FDM-based, with user-friendly interfaces and plugins for popular design software. On the other hand, industrial-grade printers, like those used in aerospace, are often far more complex, featuring advanced heating elements, multi extrusion capabilities, and stringent safety protocols.

The Future of 3D Printing

The possibilities with 3D printing are virtually limitless, and industries continue to evolve. From healthcare, where bioprinting is pushing the boundaries of organ transplants, to construction, where entire buildings can be printed layer by layer, it feels like we are only scratching the surface.

As technology advances, it will undoubtedly be exciting to see how 3D printing continues to transform not only manufacturing but also the way we think about design and production on a global scale.

Whether you’re intrigued by the science of it all or ready to embark on your own 3D printing journey, there’s never been a more exciting time to explore this innovative technology. So why not roll up your sleeves, fire up your printer, and let your imagination take flight? The only limit is how creative you are willing to get!