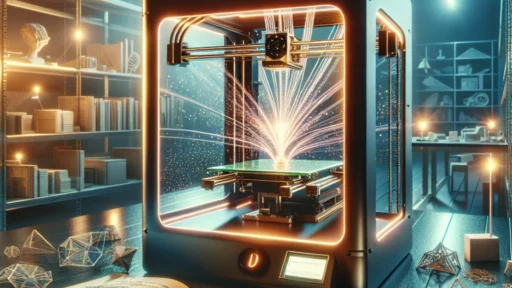

3D printing has revolutionized the way we create items, lead innovations in various industries, and even partake in hobbies. One of the fundamental aspects of 3D printing is the choice of filament, which can make all the difference in your final product. Among the most popular filament types are PLA, ABS, and PETG. If you’re new to the world of 3D printing or looking to expand your knowledge, you’re in the right place! Let’s delve into these three types of filaments, understand their properties, pros and cons, and decide which might be best for your next project.

PLA (Polylactic Acid)

PLA is perhaps the most beginner-friendly filament out there. Made from renewable resources like cornstarch and sugarcane, it’s biodegradable, making it an environmentally-friendly choice. PLA is known for its ease of use, making it the go-to option for most newcomers in the 3D printing world.

Advantages:

- Ease of Use: PLA adheres well to print beds and is less prone to warping compared to other materials. This means you can achieve great prints with minimal hassle.

- Beautiful Prints: It comes in a vibrant range of colors and can produce high-detail prints with a smooth finish, making it a popular choice for artistic projects.

- Low Odor: When printed, it doesn’t emit strong fumes, which is a plus for indoor printing.

Disadvantages:

- Heat Sensitivity: PLA can start to deform at relatively low temperatures (around 60°C), limiting its use for high-temperature applications.

- Durability Concerns: While it’s sturdy enough for many projects, PLA is more brittle than some other filaments, making it less ideal for items that require flexibility or high impact resistance.

ABS (Acrylonitrile Butadiene Styrene)

ABS is the material that most people think of when they picture classic LEGO bricks—the bright colors and durable pieces come from this tough filament. It’s a petroleum-based thermoplastic that’s known for its strength and durability.

Advantages:

- Strength and Durability: ABS offers excellent toughness and is more flexible than PLA, making it suitable for functional parts like automotive parts or tools.

- Heat Resistance: This filament can withstand higher temperatures without deforming, making it ideal for items that may be exposed to heat.

- Post-Processing Friendly: ABS can be smoothed with acetone, allowing for a neat and polished finish post-print.

Disadvantages:

- Warping Issues: ABS is notorious for warping, especially during cooling. It typically requires a heated bed and may even need an enclosed print area to maintain a stable temperature.

- Fume Emission: The fumes produced during printing can be harmful, requiring a well-ventilated area or additional extraction measures.

PETG (Polyethylene Terephthalate Glycol)

PETG might not be as widely recognized as PLA or ABS, but it’s gaining popularity for its excellent balance between the two. It’s a modified version of PET (commonly used in plastic bottles) enhanced with glycol for improved performance.

Advantages:

- Balance of Properties: PETG combines the best of both worlds—it’s strong and flexible like ABS but prints easily like PLA.

- Chemical Resistance: This filament is resistant to water and various chemicals, making it suitable for a range of projects, including items that may come into contact with liquids.

- Less Warping: PETG is less prone to warping than ABS, which means fewer headaches when dealing with print failures.

Disadvantages:

- Stringing Issues: When printing at higher speeds, PETG may lead to stringing, which can affect print quality. This means you may need to adjust print settings to mitigate this issue.

- Surface Finish: While it’s not as glossy as ABS, PETG can be a bit more difficult to sand or finish, which may limit post-processing choices.

Which Filament Should You Choose?

Choosing between PLA, ABS, and PETG really comes down to the specifics of your project and your personal preferences. If you’re just starting out and want to create decorative items or prototypes, PLA is your best bet. For functional parts that need to handle wear and tear, ABS will serve you well. And if you’re looking for something in between, PETG could offer the golden middle ground.

In a world where creativity has no bounds, knowing the characteristics of these filaments can open new doors for your 3D printing ventures. Each filament has its own unique strengths and weaknesses, and the best part is that experimentation can lead to surprising results. Whether you’re printing intricate designs or practical components, there’s a filament out there tailored for your needs. Happy printing!