The Best Practices for Maintaining Your 3D Printer

If you’re like many makers and creators today, your 3D printer likely feels like an extension of yourself—a trusty sidekick in the quest for innovation. But like any loyal companion, it requires a bit of care to keep it running smoothly. Whether you’re a seasoned pro or a curious newbie, understanding some best practices for maintaining your 3D printer can help extend its lifespan and improve the quality of your prints. So let’s dive into some practical tips for nurturing your machine!

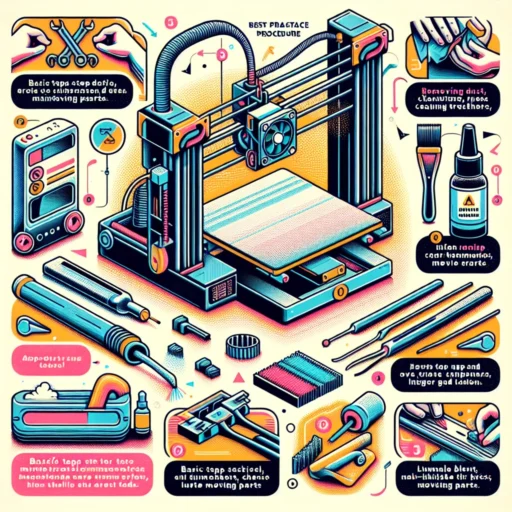

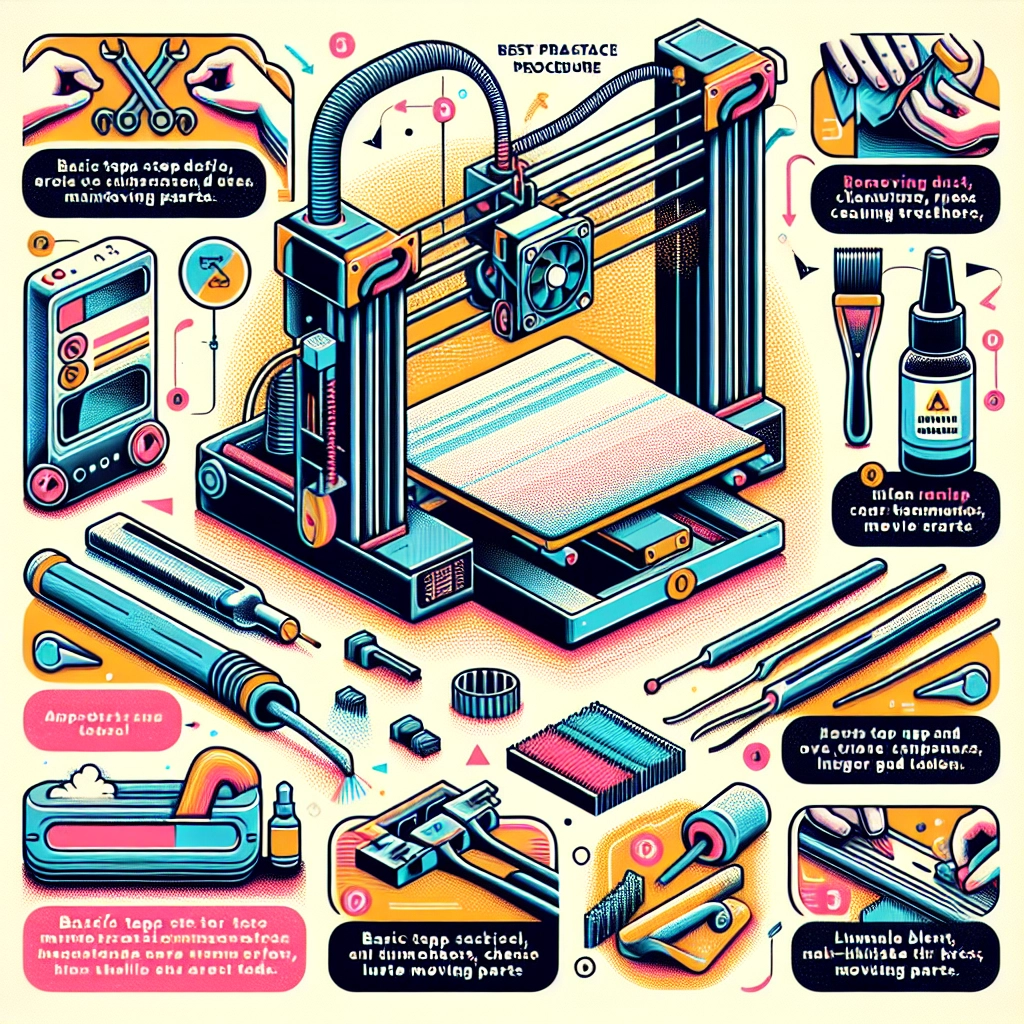

Keep it Clean

One of the simplest yet most effective practices you can adopt is cleaning your printer regularly. Dust and debris can ruin prints and cause mechanical issues, so make it a habit to wipe down surfaces, remove filament residue, and check around the build plate for any stray particles.

Don’t forget about the nozzle! It tends to be where the magic happens, but it’s also where clogs can form. You can use a needle or a small brush to remove any buildup around the nozzle. A good practice is to heat up the nozzle to its printing temperature and then gently clean it to mitigate any risk of breaking or damaging delicate parts.

Check Your Filament

Your filament plays a crucial role in the final quality of your prints. To maintain your printer, it’s essential to store it properly—keep it in a cool, dry place away from direct sunlight. Using a desiccant can help prevent moisture absorption, which can lead to brittleness and uneven extrusion during printing.

Additionally, regularly inspect your filament for tangles or knots, and replace it if you notice any signs of degradation, like discoloration or bubbling. A clean, high-quality filament can make a world of difference in your print’s appearance and functionality.

Level That Bed!

One of the most critical steps in maintaining your 3D printer is bed leveling. A misaligned build plate can lead to failed prints and wasted material, bringing frustration every time you hit "print." While some advanced printers come with auto-leveling features, it’s still important to periodically check and manually adjust your bed if needed.

Take the time to learn the bed leveling process specific to your printer model. Always make sure to level it when you change to a new type of filament or after multiple prints. It may seem like a hassle, but this small maintenance step ensures better adhesion during printing and significantly reduces the risk of print failure.

Lubricate Moving Parts

Just like a car needs oil to run smoothly, your 3D printer’s moving parts benefit from a little lubrication. Over time, the rods, lead screws, and bearings can accumulate dust or debris that might lead to friction—slowing down prints and even causing hardware failure.

Use a light machine oil or a specialized lubricant designed for 3D printers and apply it to areas that experience regular movement. Be careful not to overdo it, as excess lubricant can attract dust and create additional mess.

Monitor Temperature Settings

It’s crucial to know your printer’s temperature requirements and capabilities for both the nozzle and the heated bed. Each filament type can have different ideal temperature ranges, and while it’s tempting to just print at the default settings, adjusting temperatures based on the filament you’re using can yield superior results.

Regularly check that the heating elements are functioning well and that there are no underlying electrical issues. A small investment in a quality thermistor or temperature monitor can pay off significantly in print quality and printer health.

Stay Updated

Firmware updates can bring improvements, fix bugs, and enhance performance. Make sure you’re aware of any updates from your printer’s manufacturer and apply them when they become available. Besides, many online communities share insights and improvements that can help streamline or revamp your printing experience, so don’t hesitate to join forums or groups to stay informed.

Practice Troubleshooting

Every 3D printer will face challenges from time to time—it’s just part of the journey! Equip yourself with some basic troubleshooting knowledge. Familiarize yourself with common issues like warping, layer separation, or stringing, and have a plan for how to resolve these situations when they arise. Keep the printer’s user manual handy for quick guidance or refer to reliable online resources.

With a dash of care and attention, maintaining your 3D printer can become second nature. It’s about creating a routine that ensures your machine is always ready to bring your ideas to life. Remember, each time you invest a bit of time in maintenance, you’re setting yourself up for smoother prints, fewer headaches, and a rewarding journey through the world of 3D printing. Happy printing!