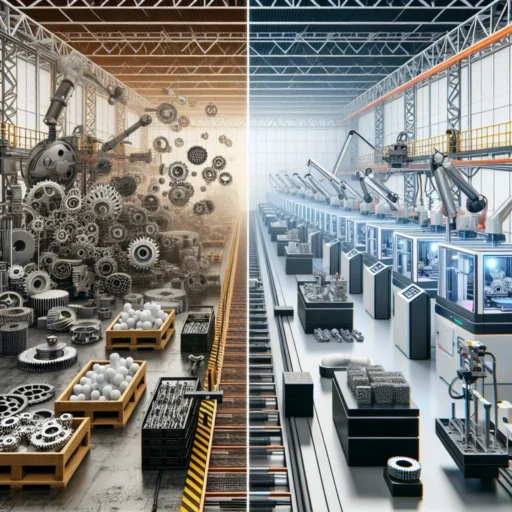

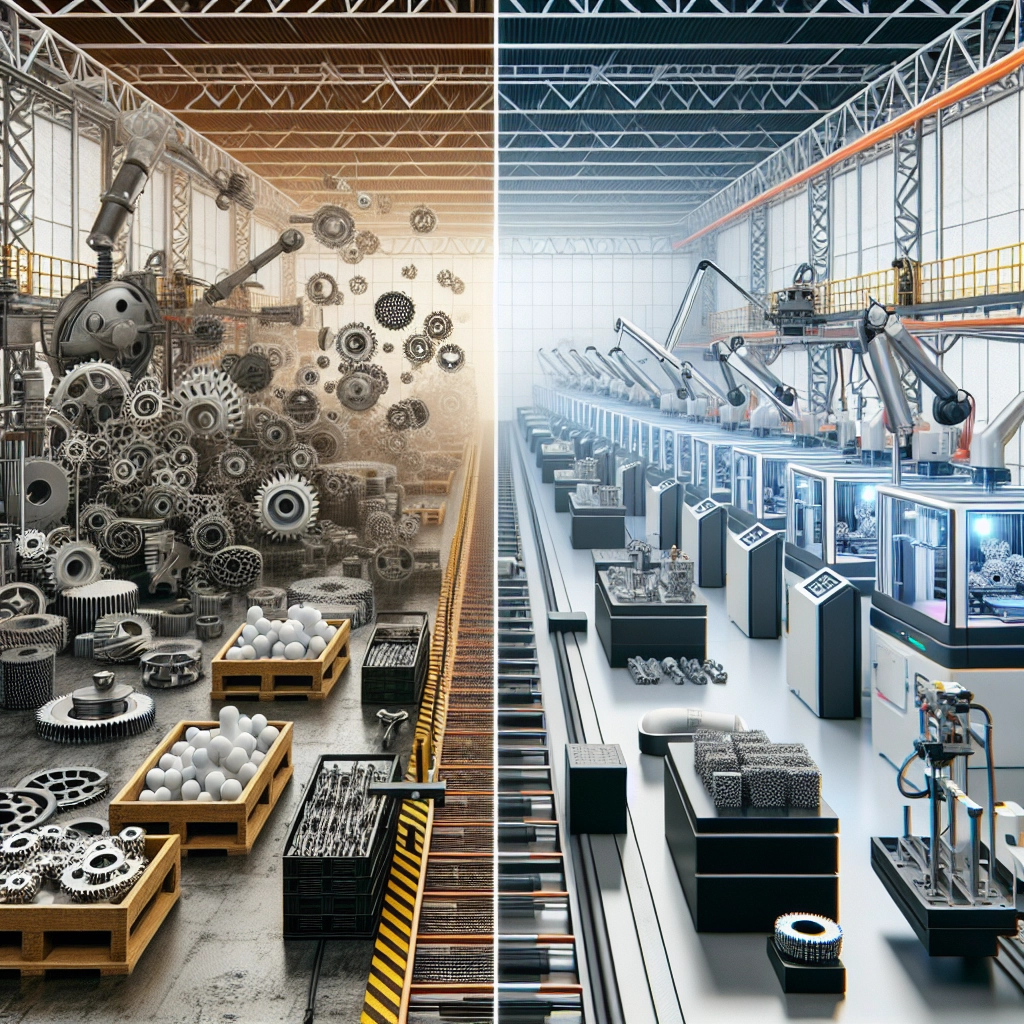

The Impact of 3D Printing on Traditional Manufacturing

If you’ve ever held a custom figurine or marveled at a complex gadget and wondered how such intricate designs come to life, you might be surprised to learn that more and more of these creations are emerging straight from the world of 3D printing. From rapid prototyping to custom fabrication, 3D printing is increasingly redefining how products are manufactured. But what does this mean for traditional manufacturing processes that have long been the cornerstone of industrial production?

A New Age of Customization

One of the most exciting aspects of 3D printing is the ability to create tailored solutions for specific needs. In traditional manufacturing, mass production often means sacrificing individuality; consumers get what’s on the shelves, and customization can be an arduous, costly process. But with 3D printing, personalization is just a design away! Need a bespoke part for your car or a unique piece of jewelry? With the right software and a 3D printer, it’s entirely possible.

This democratization of manufacturing enables everything from hobbyists designing their own tools to businesses producing small batches of specialized items. Companies no longer need to maintain extensive inventories; if they can design it, they can make it, often on-demand. That’s a game changer!

Cost Efficiency and Speed

Let’s talk numbers for a moment. Traditional manufacturing methods often involve setups that require significant investments in tooling and materials, alongside lengthy production timelines. You’re looking at labor costs, material waste, and the need for a large workforce—complex calculations that can deter even seasoned entrepreneurs.

Now, contrast that with 3D printing. Because it utilizes only the materials needed to create an object, there’s minimal waste. Many 3D printers can produce parts quickly and with incredible accuracy, which translates to shorter lead times. This quick turnaround is crucial for things like prototyping, where fast iterations can significantly propel product development. In industries like aerospace and automotive, where precision and efficiency are vital, the impact cannot be understated.

Shifting Supply Chains

The traditional supply chain model often involves multiple steps: design, manufacturing, and distribution. Each stage introduces potential bottlenecks and risks—delays, costs, and logistical headaches. Enter 3D printing, which allows localized production. Imagine a world where instead of shipping pieces of an assembled product from different parts of the globe to round out the final assembly, the entire process takes place at a local level. Parts can be printed nearby, and delivery can happen almost immediately.

This not only slashes transportation costs but also aligns with a growing trend toward sustainability. By localizing manufacturing, carbon footprints shrink, and communities enjoy greater access to job opportunities.

Challenges Ahead

But it’s not all sunshine and rainbows. As transformative as 3D printing is, there are several challenges that accompany its rise. Traditional manufacturing entities might feel threatened; the transition to this new tech can be daunting. After all, those with established processes and systems face a steep learning curve. Moreover, there are intellectual property concerns—designs can be easily replicated, leading to fears of infringement.

Also, while materials for 3D printing have vastly improved, they aren’t always ideal for every application, especially in sectors demanding high durability or strength. That means traditional manufacturing isn’t about to vanish; instead, the two can coexist and often complement each other.

A Harmonious Future

So, what does the future hold? In many ways, traditional manufacturing and 3D printing are on a collision course that could lead to cooperative innovations. By integrating additive manufacturing techniques into existing operations, businesses can achieve hybrid models that optimize their processes.

Collaboration between traditional manufacturers and those leveraging 3D technologies could lead to the creation of entirely new products, increase creativity, and push the boundaries of design. Students and researchers are increasingly diving into this fascinating blend, pointing toward a renaissance in manufacturing that embraces both old and new.

While the disruptions caused by 3D printing will certainly reshape industries, the conversation doesn’t center on replacement. Rather, it’s about evolution. Traditional manufacturing is adapting to new paradigms, integrating cutting-edge technologies while keeping its time-honored expertise. As this dynamic sector continues to grow, we’ll undoubtedly witness some incredible innovations—simultaneously respecting the craftsmanship of traditional processes and embracing the limitless possibilities of the third dimension.

In a world rapidly reshaped by technology, it’s a thrilling time to be part of this evolving landscape, watching as the boundaries of what’s possible are pushed further each day.