The Future of 3D Printing: Trends to Watch in Technology

It feels like just yesterday that 3D printing was a futuristic concept reserved for sci-fi movies and high-end manufacturing labs. Fast forward to today, and it’s making waves across multiple industries—from healthcare to fashion to construction. This remarkable technology is not only transforming how products are made, but it’s also challenging our notions of design, production, and even ownership. So, what lies ahead for 3D printing? Let’s dive into some of the key trends to keep an eye on in this dynamic field.

Democratization of Production

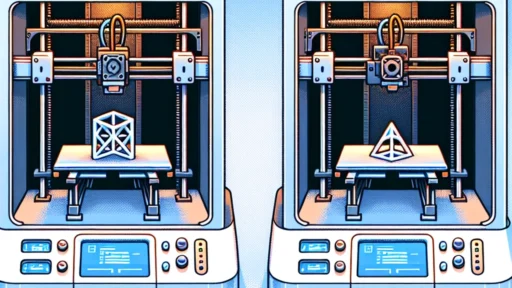

One of the most exciting trends in 3D printing is the democratization of production. As technology becomes more accessible, individuals and small businesses can create customized products without needing a massive manufacturing setup. Affordable 3D printers are popping up everywhere, from homes to community workshops (often referred to as maker spaces). This has opened the doors for aspiring entrepreneurs who want to test their product ideas without breaking the bank.

Imagine a world where you can design your own home goods, toys, or even fashion accessories and print them right from your living room. Not only does this empower creators, but it can also help reduce waste, as items can be produced on-demand, eliminating the need for large inventories and reducing overproduction.

Advanced Materials and Bioprinting

The materials used in 3D printing are evolving at breakneck speed. We’re moving far beyond traditional plastics to embrace a wide variety of advanced materials, including metals, ceramics, and even biological materials. These innovations are paving the way for a new frontier: bioprinting.

Picture this: scientists are experimenting with bio-inks made from living cells, which could one day lead to the ability to print tissues or even organs for transplant. While we’re still at the nascent stage of this technology, the potential is staggering. It could fundamentally change healthcare as we know it by providing personalized solutions for patients that reduce waiting times and improve outcomes.

Industrial Applications and Custom Manufacturing

Industries are beginning to fully recognize the power of 3D printing in streamlining production processes. Companies like Boeing and GE are using additive manufacturing to create complex parts that traditional methods struggle to replicate. This shift enables not only lighter and stronger components but also significant cost savings in materials and manufacturing time.

Custom manufacturing is becoming increasingly popular, allowing for tailored solutions that meet specific needs. For example, in automotive or aerospace sectors, producing unique parts on demand can result in quicker turnaround times and more agile supply chains. As businesses continue to adopt 3D printing, expect it to become standard practice in production lines around the globe.

Sustainability and Eco-Friendly Practices

With growing concerns about climate change and environmental pollution, the sustainability aspect of 3D printing is a trend worth noting. Many companies are now focusing on eco-friendly materials and processes. For instance, some are utilizing biodegradable plastics or recycling waste materials into print-ready filaments.

Moreover, 3D printing can reduce carbon footprints by localizing production and minimizing transportation needs. As organizations increasingly prioritize sustainability in their operations, 3D printing offers an innovative and impactful avenue for achieving environmental goals.

Software and AI Integration

As technology advances, software development is rapidly following suit. Advanced design software and AI-enabled tools are reshaping how we create 3D models, making it easier than ever for designers and engineers to bring their visions to life. With AI, the design process can not only automate tedious tasks but also generate optimized models for performance and material usage.

Additionally, using AI in 3D printing can enhance the quality control process, making production more efficient and less prone to errors. As these technologies converge, expect to see an even more streamlined and intelligent production process.

The Rise of 3D Printing in Healthcare

The healthcare sector illustrates one of the most promising applications of 3D printing technology. From prosthetics and dental implants to surgical instruments and patient-specific anatomical models, 3D printing is revolutionizing medical practice. This technology can create customized solutions tailored to individual patients, leading to enhanced efficacy and better health outcomes.

Moreover, the potential to create personalized medicine approaches—such as printed medications or drug delivery systems—could further enhance treatment protocols. With ongoing research and advancements, it’s clear that 3D printing will play a pivotal role in the future of healthcare.

As we embark on this thrilling journey into the future of 3D printing, it’s clear that the technology will continue to evolve and surprise us in ways we can hardly imagine today. Embracing these trends can not only reshape industries but also empower individuals, foster creativity, and offer solutions to some of our planet’s pressing challenges. Whether you’re an entrepreneur, an engineer, an artist, or just a curious mind, keeping an eye on 3D printing is essential. The possibilities are endless, and the future looks undeniably bright!