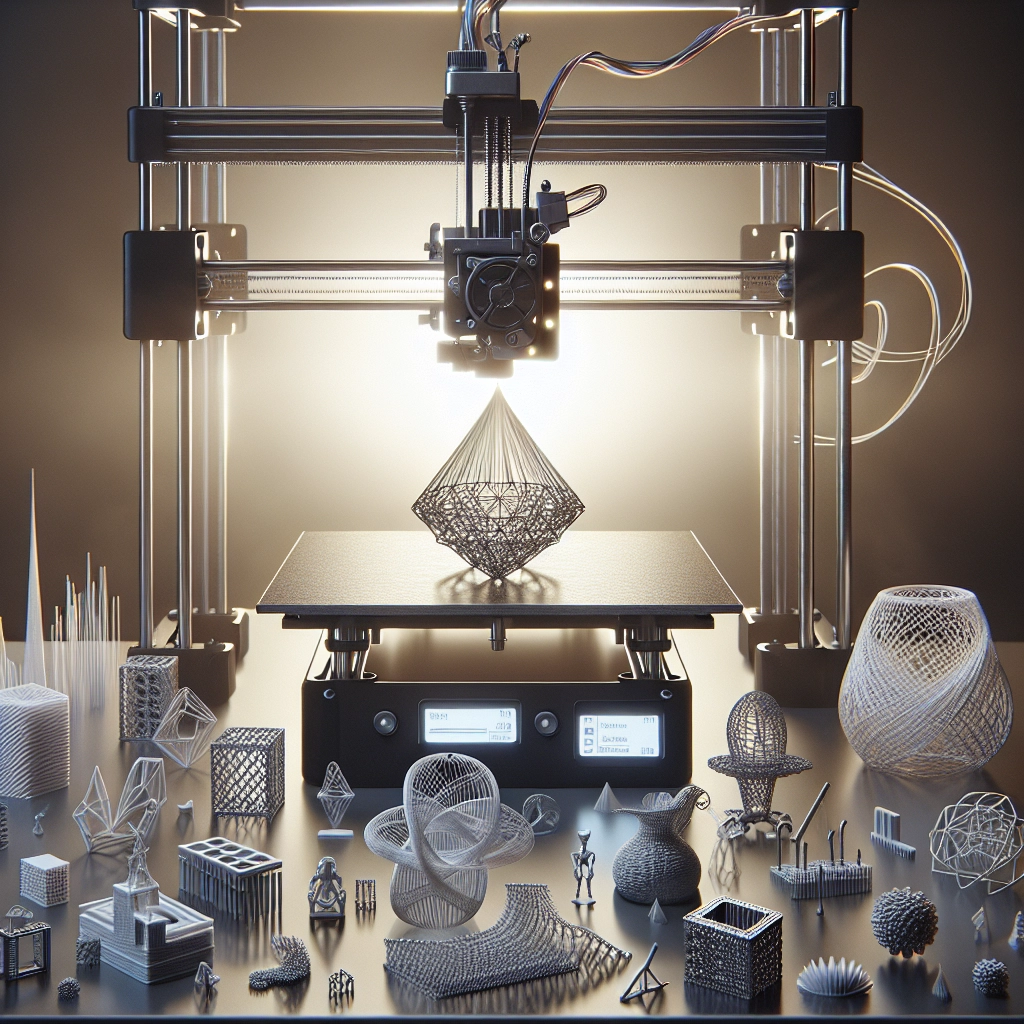

Exploring the Versatility of Nylon Filament in 3D Printing

When it comes to 3D printing, the filament you choose can make a world of difference. Among the many materials available, nylon has emerged as one of the most versatile options on the market. If you’ve ever wondered what makes nylon filament stand out, or if you’re thinking of giving it a whirl, you’re in for a treat. Let’s delve into the wonders of nylon filament and see why it’s capturing the hearts (and printers) of makers everywhere.

What is Nylon Filament?

Nylon, or polyamide, is a synthetic polymer that boasts remarkable properties, making it a favorite in numerous applications, including textiles, automotive components, and, of course, 3D printing. When printed, nylon is known for its strong, flexible, and durable nature. This unique combination of qualities allows it to excel in applications where traditional materials might falter.

Strength and Durability

One of the most compelling reasons to use nylon filament is its strength. It’s often compared to other common filaments like PLA and ABS, and nylon stands tall in this comparison. Not only is nylon resistant to impacts and wear, but it’s also less prone to breaking or snapping under stress. This durability makes it an ideal choice for functional parts such as gears, hinges, and other components that require both precision and reliability.

Nylon also has a remarkable ability to withstand temperature fluctuations and harsh environments. It’s more tolerant of heat compared to standard plastics, giving it an edge when used in settings exposed to changing temperatures or mechanical friction. If you’re designing something that needs to endure wear and tear, nylon might just be your go-to filament.

Flexibility and Resistance

What’s cool about nylon is its flexibility. Unlike some louder and harsher filaments, nylon can bend without breaking, which is perfect for creating parts that need to flex or fit into tight spaces. Imagine printing items like protective casings or even wearables that conform comfortably to the shape of your body. With nylon, achieving that snug fit becomes a breeze.

Another great feature of nylon is its resistance to chemicals and abrasion. This makes it a favorite for creating custom tools, fixtures, and even outdoor equipment. Whether you’re in a workshop or taking your creations into nature, nylon can take a beating and keep on going.

Printing Process and Challenges

Now, while nylon has a plethora of benefits, it’s worth mentioning that 3D printing with nylon filament comes with its own set of challenges. For one, nylon has a reputation for being tricky to print due to its need for proper bed adhesion and temperature settings. Many recommend using an enclosure to maintain a consistent print temperature and prevent warping. However, if you can master these settings, the results are often well worth the effort.

If you’re a bit nervous about diving into nylon printing, don’t fret! There are plenty of resources out there—tutorials, forums, and user guides—that can help you troubleshoot any issues you encounter. Plus, many filament manufacturers have developed nylon blends that are optimized for easier printing, which can be a game-changer for those just starting out.

Color Options and Customization

One of the best things about nylon filament is the variety of colors and finishes available. Whether you’re looking for a vibrant hue for a decorative project or something more subdued for practical applications, there’s likely a nylon option out there for you. Moreover, nylon is known for its ability to hold dyes well, so customization is limitless. You can easily transform your printed objects with a splash of color, giving you the freedom to express your creativity!

Applications of Nylon Filament

The versatility of nylon filament opens up a vast array of applications. You can create everything from prototypes and functional tools to end-use products like drone parts or bike accessories. Hobbyists have even experimented with nylon for chic jewelry and decorative items—talk about creativity!

Industries are also jumping on the nylon bandwagon. From manufacturing to healthcare, many companies are utilizing nylon parts for their strength and reliability. It’s fascinating to see how a single filament can play a pivotal role in both personal projects and professional environments.

As the world of 3D printing continues to expand, it’s exciting to see how materials like nylon are at the forefront of innovation. Its unique properties make it a compelling choice for anyone looking to create something that stands the test of time, whether it’s for hobby or necessity. So, if you’re contemplating your next project, why not give nylon filament a try? You might just discover a newfound love for this superb material!