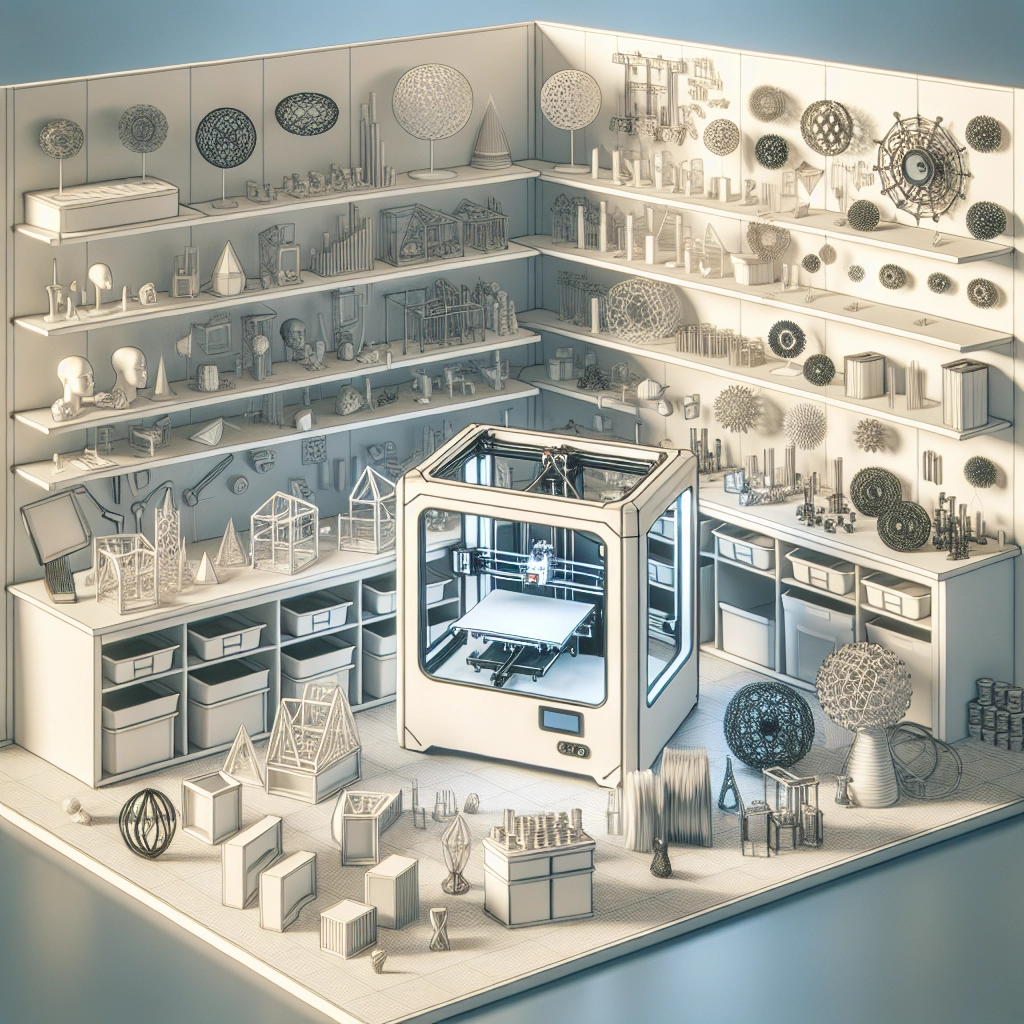

Using 3D Printing for Prototyping: What You Should Consider

In recent years, 3D printing has revolutionized the way we think about design and prototyping. Whether you’re an entrepreneur brainstorming a new product or an engineer fine-tuning existing concepts, 3D printing is a game-changer. It’s like having a mini-factory right at your fingertips, allowing you to bring your ideas to life in ways that were once only possible through traditional manufacturing processes. However, while the technology is exciting, there are some essential factors to consider before diving headfirst into using 3D printing for your prototyping needs.

Understanding the Basics of 3D Printing

First things first, it’s crucial to understand how 3D printing works. At its core, the process involves creating three-dimensional objects from a digital file by layering material—often plastic—until the desired shape is achieved. This means you can produce highly intricate designs and tailored features in ways that traditional methods simply can’t match. But with great power comes great responsibility.

Material Selection Matters

One of the most fundamental considerations is the choice of materials. 3D printing accommodates a myriad of materials, from thermoplastics and resins to metals and even ceramics. Each material has its own properties, like strength, flexibility, heat resistance, and finish. For example, if you’re prototyping a component that needs to endure high temperatures, then choosing a heat-resistant plastic or metal would be paramount. Additionally, each material has different implications for cost and production time. So, take a couple of moments to assess the end-use of your prototype to make the best choice.

Design Complexity

Unlike traditional manufacturing, which can impose limitations on shape and design, 3D printing embraces complexity. Want to create a part with intricate internal structures or unique geometries? You can do that! This flexibility allows for innovation and problem-solving that’s incredibly exciting. However, keep in mind that complex designs can still lead to longer print times and, sometimes, challenges in strength and stability. If your prototype requires assembly, think about how your 3D-printed parts will come together. Regularly reviewing designs in relation to the printing process can save you time and money in the long run.

Scale and Production Time

How many prototypes do you need? One of the great things about 3D printing is that it’s perfect for low-volume production. Whether you’re making a single prototype or several copies, 3D printing can adapt to your needs. However, if you’re considering scaling up production or need a large batch of parts, you might want to reconsider your approach. While 3D printing is quick for small runs, traditional manufacturing methods can be more efficient and cost-effective for large volumes.

Cost Considerations

When it comes to budgeting, be mindful that 3D printing isn’t necessarily the cheapest option upfront, particularly for high-end materials and advanced printers. But it’s essential to see the bigger picture. The ability to iterate quickly based on feedback can often outweigh initial costs. Plus, the combination of saved labor costs and reduced waste makes it an attractive option for many. It’s worth crunching the numbers—factoring in materials, printing time, and any post-processing steps you’ll need.

Prototyping Iterations

One of the most significant advantages of 3D printing is the opportunity for rapid prototyping. You can go from idea to a tangible prototype in record time. This quick turnaround allows for iterative testing and feedback, enabling you to refine your design based on real-world applications. Remember, the design process is rarely linear. Embrace taking your prototype through several iterations, as this will lead you closer to a final product that meets your expectations and requirements.

Post-Processing

Once your prototype is printed, don’t forget about post-processing. This step can involve sanding, painting, or applying different finishes, depending on the desired aesthetic and functional qualities. While 3D prints can be used straight off the printer, attention to detail here can significantly enhance the professional quality of your prototype.

Finding the Right Service

Unless you own a 3D printer, you might consider partnering with a 3D printing service. Research local options or online platforms that cater to your specific needs. Look at reviews and ask about the types of materials they work with, turnaround times, and the design support they offer. Building a solid relationship with a reliable service provider can make a world of difference in your prototyping journey.

In wrapping up, 3D printing is an exciting frontier in the realm of prototyping, offering countless advantages that can streamline your product development process. By keeping in mind the essential considerations—from material selection to post-processing—you’ll be well on your way to crafting stellar prototypes that can stand the test of time, market scrutiny, and innovation. Remember, experimentation is the name of the game, so don’t shy away from exploring what 3D printing can do for you!