The Impact of 3D Printing on Modern Manufacturing

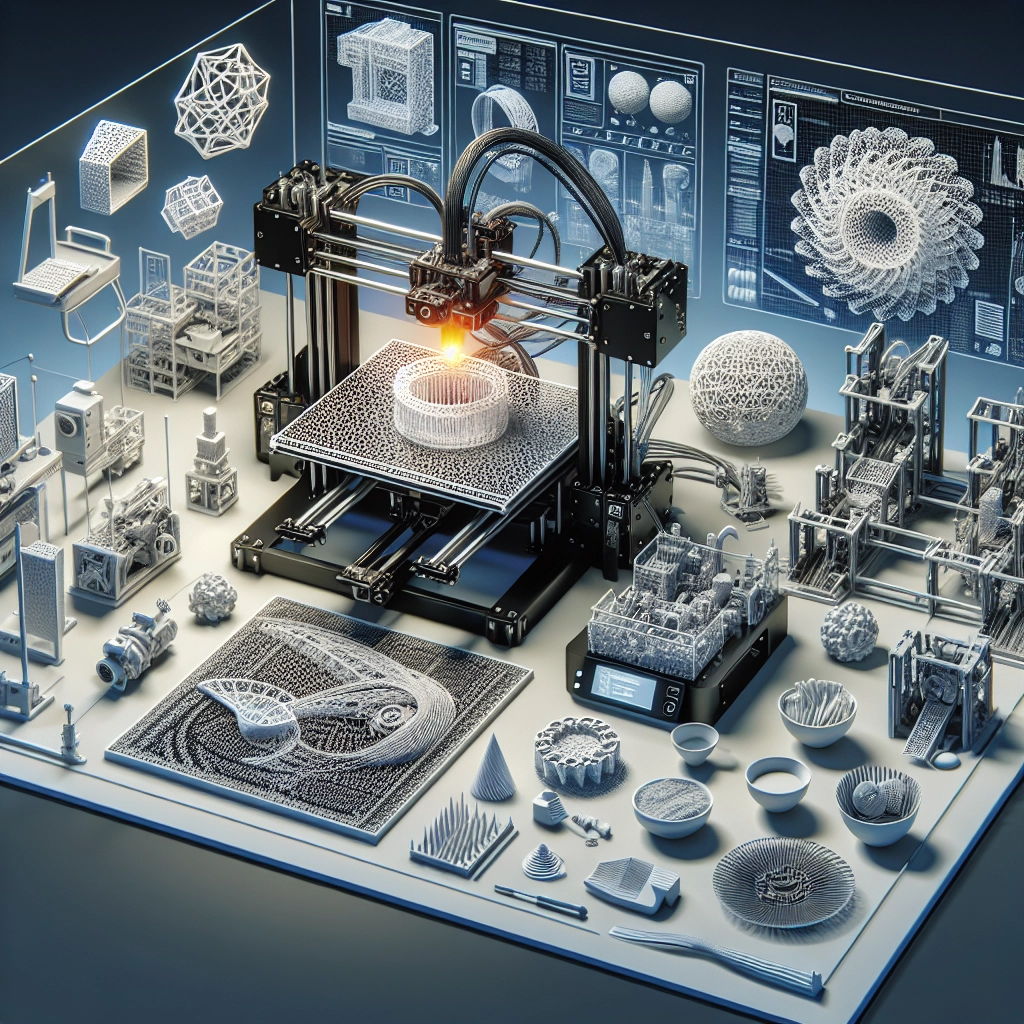

In recent years, 3D printing has captured the imagination of entrepreneurs, engineers, and hobbyists alike — and for good reason! This groundbreaking technology has not only transformed the way products are developed and produced but is also revolutionizing industries from healthcare to aerospace. So, what exactly is the impact of 3D printing on modern manufacturing? Let’s dissolve the complexities and take a friendly tour through this fascinating subject.

A Game-Changer for Prototyping

One of the most remarkable effects of 3D printing is its ability to streamline prototyping. Traditional manufacturing processes often require expensive molds and tooling, but with 3D printing, companies can create prototypes quickly and at a fraction of the cost. This means that designers and engineers can test their ideas in real-time, allowing for faster iterations and refinements. Imagine being able to bring your ideas to life in days instead of months — that’s the power of this technology!

Furthermore, this rapid prototyping capability has fueled innovation across various sectors. In industries like automotive, companies can experiment with new designs, optimize performance, and enhance aesthetics without the heavy burden of cost and time delays. The quicker the feedback loop, the better the end product you can create.

Customization at Its Finest

Gone are the days of one-size-fits-all manufacturing. One of the most exciting aspects of 3D printing is its capacity for customization. Whether it’s a bespoke prosthetic limb tailored to the unique shape of a patient’s limb or a personalized piece of jewelry, 3D printing allows for an unprecedented level of individualization. In healthcare, for example, 3D-printed implants are made to match the patient’s anatomy, resulting in a better fit and improved outcomes.

This customization extends to other fields as well. In the world of fashion, designers can create unique, limited-edition garments that set themselves apart from mass-produced items. Consumers increasingly crave products that reflect their personality, and 3D printing satisfies this demand beautifully.

Reducing Waste and Boosting Sustainability

As the world grapples with environmental challenges, 3D printing is emerging as a potential savior in the production landscape. Traditional manufacturing processes often generate substantial waste due to excess materials and inefficient production methods. On the other hand, additive manufacturing—another name for 3D printing—builds items layer by layer, using only the necessary materials to create a product.

This reduction in waste is crucial, especially if we want to move toward more sustainable practices. Moreover, the ability to print parts on demand can alleviate the need for large inventories, thus reducing the overall environmental footprint of transportation and storage.

Expanding Possibilities in Education and Training

3D printing isn’t just shaking up the industrial scene; it’s also making waves in education. Schools and universities are increasingly integrating 3D printing into their curricula, allowing students to engage in hands-on learning experiences. Imagine students in engineering programs designing and printing their projects, gaining invaluable insights into design, manufacturing, and problem-solving.

Furthermore, continued advancements in virtual and augmented reality paired with 3D printing offer amazing opportunities for training and simulations. Industries like aviation or medicine can simulate real-life scenarios, enabling trainees to practice in a safe, controlled environment before stepping onto the actual floor.

Challenges, But Not Unbeatable

While the impact of 3D printing is overwhelmingly positive, it doesn’t come without its challenges. Intellectual property concerns loom large, as copying designs can be as simple as downloading a file. Moreover, there are limitations to the types of materials that can be used and the scale at which 3D printing operates. But it’s crucial to remember that every new technology faces hurdles; the key is how we tackle them.

As we look ahead, the integration of 3D printing with other technologies, like artificial intelligence and advanced robotics, could push the boundaries even further. More companies are adopting hybrid models that combine traditional manufacturing with 3D printing, allowing for more efficient production lines.

In summary, the implications of 3D printing in modern manufacturing are profound, promoting innovation, customization, and sustainability while providing unique educational opportunities. As this technology continues to evolve, it promises to reshape industries and enhance the way we live and work. The future is undoubtedly bright, and it’s exciting to think about what new possibilities 3D printing will unveil next!