3D Printing Myths Debunked: What You Need to Know

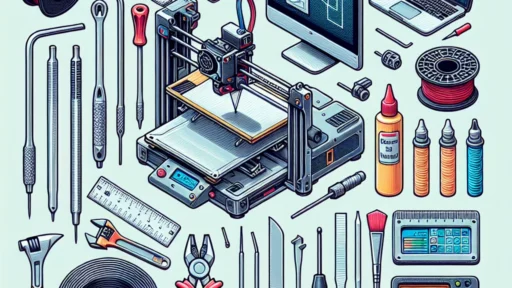

3D printing has been one of those technologies that sparks a lot of excitement and buzz. From creating custom car parts to building houses, the applications are seemingly endless! But with all that hype, there are also a fair share of myths and misconceptions floating around. If you’re thinking about diving into the world of 3D printing, it’s crucial to separate fact from fiction. Let’s take a look at some of the most common myths surrounding 3D printing and set the record straight!

Myth 1: 3D Printing is Only for Engineers and Experts

One of the most persistent myths is that you need to be a technical wizard or a seasoned engineer to get started with 3D printing. While having a background in engineering might help, it’s by no means a prerequisite. Nowadays, there are a plethora of user-friendly software options designed for beginners. Programs like Tinkercad allow anyone to create 3D models with intuitive drag-and-drop features. Plus, numerous online communities and forums are available where you can seek help, share ideas, and connect with fellow 3D printing enthusiasts.

Myth 2: 3D Printing is Incredibly Expensive

While it’s true that some high-end 3D printers can cost quite a bit, the landscape has changed dramatically over the years. You can find budget options that are quite effective for home use, with prices dropping to under a few hundred dollars. Filament and material costs have also decreased significantly, meaning that 3D printing is becoming more accessible to hobbyists and entrepreneurs alike. In many cases, the costs can be offset by the savings from producing custom parts or prototypes in-house instead of outsourcing them.

Myth 3: 3D Printing is a Slow Process

Many people picture 3D printing as a slow-moving process where you wait hours for a single object to materialize before your eyes. Yes, some designs can take a while to print, especially if they’re large or intricate. However, the speed of 3D printers has improved remarkably over the years. With advancements in technology, many printers can produce decent-sized items in a matter of hours. Plus, there’s no need to limit yourself to one print at a time. You can run multiple prints simultaneously or create smaller items that print quickly, allowing you to maximize your time and materials.

Myth 4: 3D Printed Objects are Fragile and Low Quality

If you’re picturing 3D printed items as flimsy and unreliable, think again! The reality is that the durability of a 3D printed object highly depends on the material used and the printing technique employed. In fact, professional-grade printers use industrial materials, such as metal and advanced plastics, to create robust products. For hobbyists, there are also numerous filament types available, including flexible and reinforced options, offering strength and durability without compromising quality. With the right setup, 3D printing can even produce parts that rival those made through traditional manufacturing methods.

Myth 5: 3D Printing Will Replace Traditional Manufacturing

While it’s true that 3D printing will disrupt certain manufacturing processes, it’s unlikely to completely replace traditional methods anytime soon. Each form of manufacturing has its unique strengths and weaknesses. For large-scale production runs, conventional methods are usually more efficient. However, 3D printing excels in creating custom, one-off designs or small batches where flexibility and rapid prototyping make a significant difference. Rather than a replacement, think of 3D printing as a complementary tool that opens up new avenues for creativity, innovation, and personalization in manufacturing.

Myth 6: Anyone Can Just Download a Design and Print It

This one sounds great in theory, but 3D printing isn’t quite as simple as clicking ‘download’ and ‘print.’ While there are millions of open-source designs available online, not all of them are printer-ready. Often, you may need to tweak the design to fit your printer’s specifications or resolve issues that could arise during the printing process. Additionally, understanding the fundamentals of slicing software—the tool that converts 3D models into instructions for 3D printers—can help you refine your projects and troubleshoot any hiccups along the way.

The Bottom Line

Embracing the world of 3D printing can feel overwhelming, especially with so many myths swirling about. But don’t let misconceptions hold you back! Armed with the right information, you can unleash your creativity and leverage this innovative technology in ways you never imagined. Whether it’s for personal projects, crafting prototypes for your budding business, or even exploring art, 3D printing is a dynamic medium that offers endless possibilities. So, roll up those sleeves, fire up that printer, and let your imagination fly!