3D Printing Innovations: What’s New in the Industry?

3D printing has come a long way from its humble beginnings in the 1980s. What was once a niche technology primarily used for prototyping has evolved into a game-changer across various industries, including healthcare, automotive, aerospace, and even fashion. If you’ve been following the buzz lately, you know that the innovations in 3D printing are coming at lightning speed. Let’s take a closer look at some of the most exciting advancements in the industry that are redefining what’s possible.

Materials Revolution

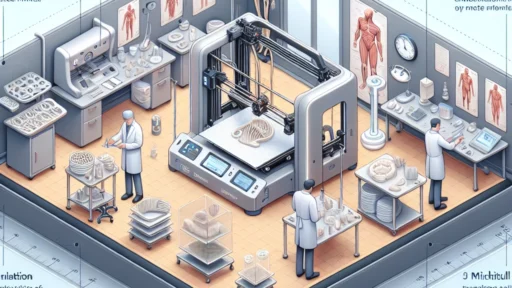

One of the most groundbreaking advancements in 3D printing is the development of new materials. Gone are the days when plastic was the only option on the table. Nowadays, researchers are exploring everything from biodegradable plastics to metals, ceramics, and even bioinks that can print human tissue. For example, researchers at the University of Florida recently developed a 3D printer capable of creating biological tissues that could potentially revolutionize organ transplants. Imagine a world where organ rejection is a thing of the past thanks to personalized 3D-printed organs!

Moreover, new composite materials are emerging that combine different elements for enhanced strength, flexibility, and durability. This versatility opens up a myriad of applications, from aerospace components that are lighter yet stronger to consumer products that are more sustainable.

Speed and Efficiency

Speed is another area where 3D printing is making leaps and bounds. Traditional 3D printing methods can be painstakingly slow, but new techniques are changing that. For instance, Continuous Liquid Interface Production (CLIP) technology can produce objects at an astonishing rate—up to 100 times faster than conventional printing methods. This innovation not only allows for quicker prototyping but also accelerates the time it takes to go from concept to final product.

Additionally, advancements in multi-material printing are enabling the simultaneous production of complex components with various materials. This can drastically reduce assembly times and improve overall efficiency in manufacturing processes.

Customized Solutions

Customization is at the heart of 3D printing, and recent innovations are taking this capability to new heights. From bespoke medical implants tailored to fit an individual’s anatomy to customized footwear designed for optimal comfort and performance, the possibilities are endless.

Brands like Adidas and Nike are already making waves in this space by offering custom 3D-printed shoes tailored to a customer’s unique foot structure. This level of personalization not only enhances user experience but also reduces waste by producing only what is needed.

Sustainability Efforts

As we become increasingly aware of our environmental footprint, 3D printing is stepping up to offer more sustainable alternatives. Researchers and companies are actively developing ways to utilize recycled materials in 3D printing. For example, some innovators are working on creating filaments made from recycled ocean plastics, turning trash into treasure.

Furthermore, the additive nature of 3D printing—where material is added layer by layer—generally results in less waste compared to traditional subtractive manufacturing methods, where material is removed from a larger block. This makes 3D printing an attractive option for companies looking to reduce waste and promote sustainability.

Integration with AI and Automation

The rise of artificial intelligence is providing novel ways to enhance 3D printing processes. Machine learning algorithms can optimize printer settings for different designs, significantly improving the quality and consistency of the final product. AI can also predict potential issues during the printing process, enabling real-time adjustments that minimize errors.

Automation also plays a crucial role in making 3D printing more accessible. With automated systems, businesses can set up entire 3D printing farms that run production with little human intervention. This not only increases efficiency but also reduces labor costs, making it an enticing option for manufacturers.

The Future is Brighter

As we look ahead, the intersection of 3D printing with emerging technologies like AI, IoT, and advanced materials science suggests that the industry is on the brink of another major transformation. From healthcare to fashion and beyond, the innovations in 3D printing are not just exciting; they’re potentially life-changing.

With new applications emerging every day, it’s exhilarating to consider how these advancements could reshape not only industries but our daily lives. As we continue to push the boundaries of what’s possible, one thing is clear: the future of 3D printing holds endless opportunities, and it’s just getting started. So, whether you’re a tech enthusiast or a casual observer, keep your eyes peeled—the next revolutionary development could be just around the corner!