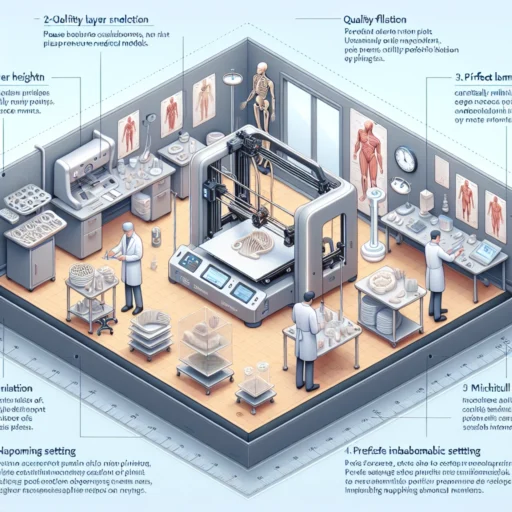

Best Practices for 3D Printing Medical Models

In the rapidly evolving world of medical technology, 3D printing has emerged as a game-changer. From surgical planning to patient education, the ability to create accurate medical models has revolutionized how healthcare providers approach treatment. But to maximize the potential of 3D printing in a medical setting, it’s crucial to adhere to certain best practices. Let’s dive in!

Understand the Purpose and Applications

Before even beginning the 3D printing process, it’s essential to clarify the purpose of the model you’re creating. Are you printing for surgical preparation? Patient education? Or perhaps for anatomical study? Different applications require different approaches regarding design, materials, and detail levels.

For example, surgical models tend to prioritize realism and precision, while educational models might focus more on illustrating specific concepts. Knowing the end goal will guide your choices throughout the process.

Choose the Right Material

In 3D printing, the choice of material can significantly affect the quality and usability of the final product. Common materials for medical models include:

- PLA (Polylactic Acid): Easy to print and environmentally friendly, but may not be sturdy enough for surgical simulations.

- ABS (Acrylonitrile Butadiene Styrene): Stronger than PLA, making it suitable for functional parts, though it can be trickier to print due to warping.

- TPU (Thermoplastic Polyurethane): Flexible and ideal for models that require a degree of softness, like skin or organs.

- Resin: High-resolution prints with great details but can be costly and require additional post-processing care.

Understanding the properties of these materials will help you select the most appropriate one based on your needs.

Leverage Advanced Scanning Technology

Creating a 3D model often begins with gathering precise data. This is where advanced scanning technology comes into play. Techniques such as MRI, CT scans, and even ultrasound images can provide the detailed anatomical data needed for accurate model creation. The more precise the scan data, the better your model will turn out.

Once you have this data, utilize software tools to convert the medical imaging files into a 3D printable format. Popular tools include MeshLab and 3D Slicer, which can help you clean and modify the raw data to fit your needs before printing.

Ensure Accurate 3D Modeling

A great 3D print starts with an equally great digital model. Software like Blender, AutoCAD, or Tinkercad can help you modify or enhance your models after you’ve converted your scans. Pay attention to details, ensuring key anatomical features are accurately represented, especially if the model will be used for medical training or surgical planning.

It’s also critical to consider scale. Make sure to translate the measurements from your scans into a usable model size, as exaggerated or minuscule features can lead to misunderstandings during procedures.

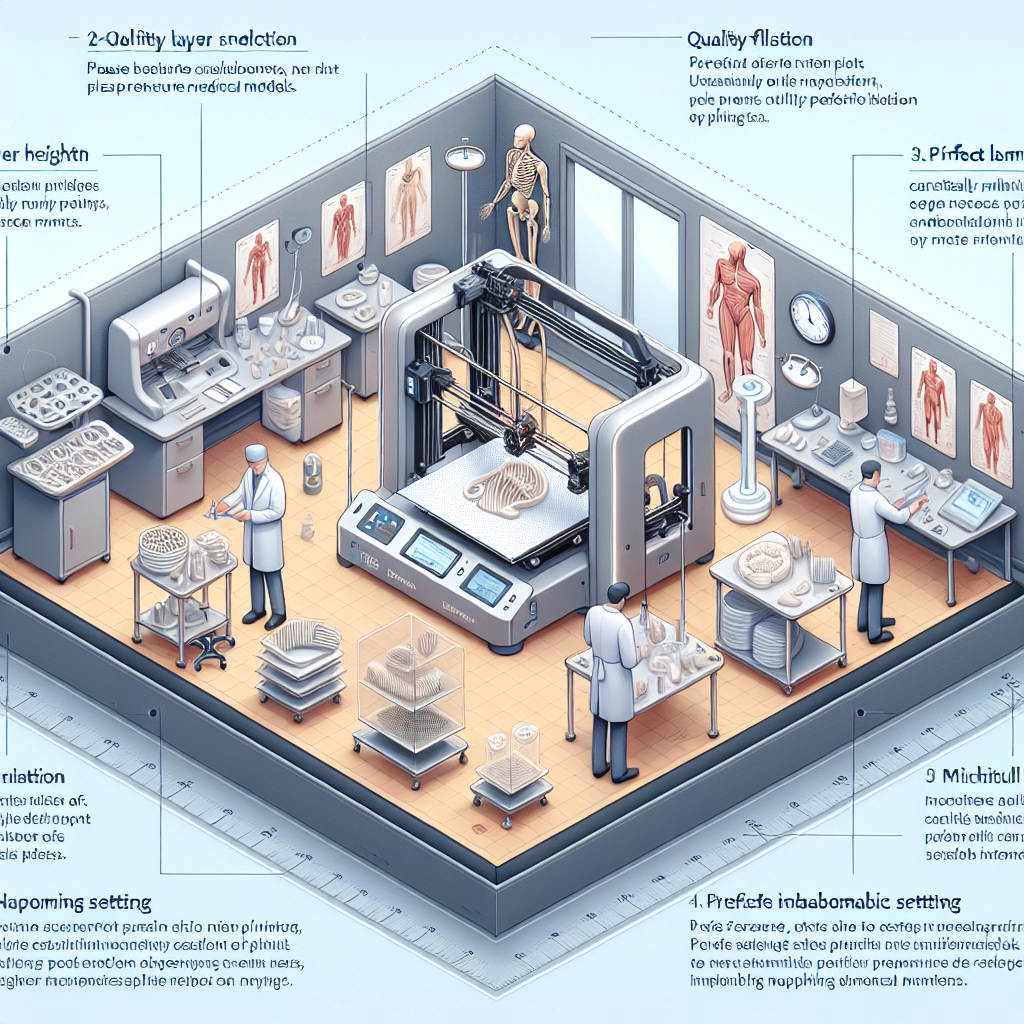

Optimize the Printing Process

When it comes to the actual 3D printing, optimization is key. This means adjusting parameters like layer height, print speed, and infill density based on the material you’re using.

For medical models, a finer layer height may be advantageous for capturing intricate details, while a higher infill density might be necessary for parts that need added strength. Don’t forget to consider the orientation of the print, as it can significantly affect structural integrity and surface finish.

Post-Processing with Care

Once your model is printed, the work isn’t done yet. Post-processing can make or break the final output. Depending on your choice of material, you may need to sand, paint, or treat the model to achieve the desired finish. This is particularly important for surgical models, where realism can significantly enhance the experience for both surgeons and patients.

If your model requires assembly or integration with other components (like electronics for interactive training tools), take care to ensure all parts fit together accurately.

Collaboration is Key

Lastly, never underestimate the power of collaboration in the 3D printing process. Engaging with healthcare professionals throughout the design and printing phases can yield invaluable insights that improve the model’s utility. Whether you’re sharing iterations with surgeons, medical educators, or patients, feedback will help ensure that the final product meets the specific needs of its intended audience.

3D printing medical models is not just a technological endeavor; it’s a way to bridge the gap between complex medical procedures and human understanding. By following these best practices, you can create models that are not only functional but also profoundly beneficial for the patients and healthcare professionals who rely on them. Embrace the journey and keep exploring the remarkable possibilities that lie within the realm of 3D printing!