Understanding Different Types of 3D Filaments and Their Uses

If you’re diving into the world of 3D printing, you’re probably aware that choosing the right filament is just as important as having a good printer. With various types of 3D filaments available, each comes with its unique characteristics, uses, and considerations. Whether you’re a hobbyist looking to create intricate models or a professional aiming for functional prototypes, understanding the different types of filaments can help you make the right choice for your project. Let’s explore some of the most popular filaments, what makes them unique, and when to use each one.

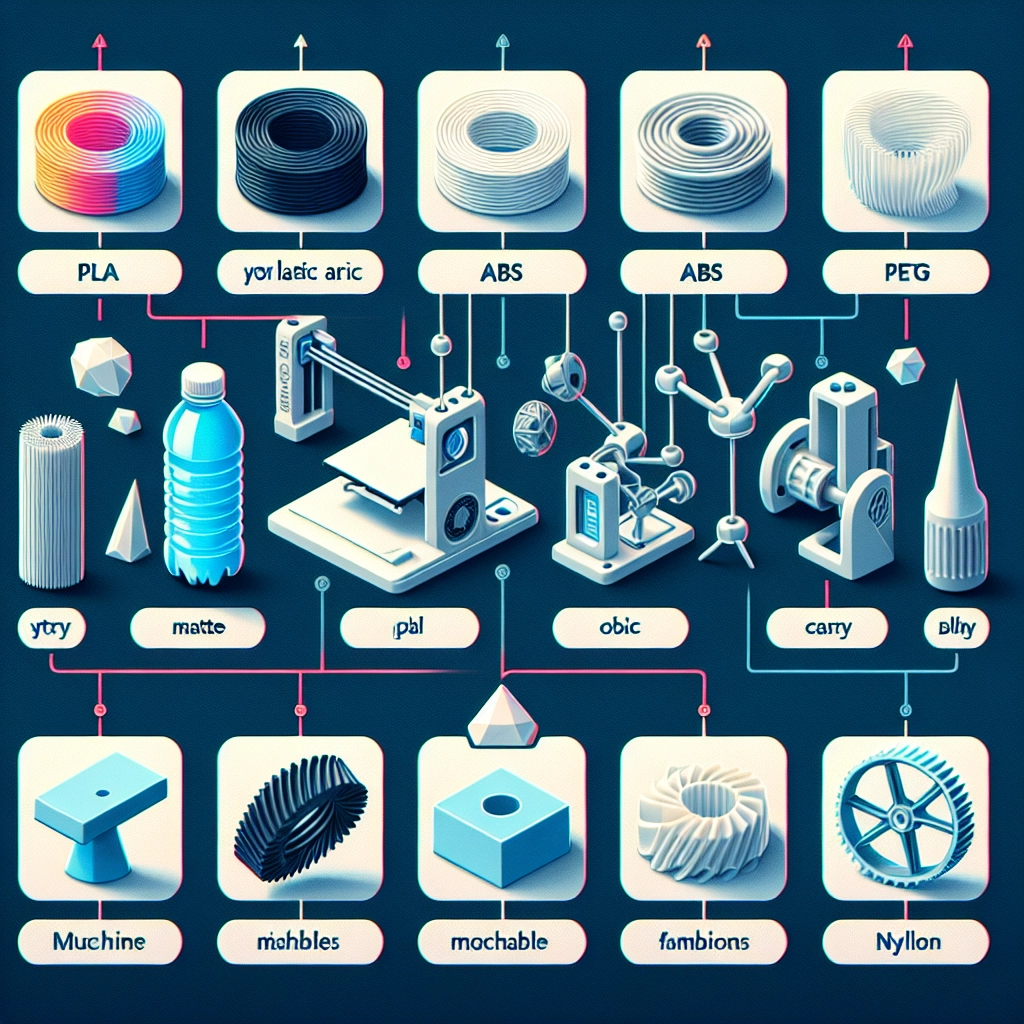

1. PLA (Polylactic Acid)

PLA is often the go-to filament for beginners and seasoned printer users alike because it’s user-friendly and widely available. Made from renewable resources like corn starch, it’s biodegradable, making it a great eco-friendly option.

Uses

- Prototyping: PLA prints have a fine detail and smooth finish, making them ideal for visual prototypes.

- Educational Projects: Its ease of use makes it perfect for classrooms and workshops.

- Artistic Creations: Artists often choose PLA for sculptures and other artistic work because it’s versatile and comes in various colors and finishes.

Considerations

While PLA is easy to print, it has a lower melting point, so it’s not suitable for high-temperature applications. It can also be brittle, which may be a concern for functional parts.

2. ABS (Acrylonitrile Butadiene Styrene)

ABS is a favorite among those needing tougher and more heat-resistant parts. It’s the material behind classic LEGO bricks, which testifies to its durability.

Uses

- Functional Parts: ABS is great for items that need to withstand wear and tear, like gears or enclosures.

- Post-Processing: It’s ideal for models that require sanding or acetone smoothing for a cleaner finish.

- Automotive Applications: Its chemical resistance makes it suitable for car parts and other automotive components.

Considerations

ABS can be challenging to print for beginners—it’s more prone to warping as it cools than PLA. Some users also express concerns about the fumes when printing, so ensure proper ventilation when working with it.

3. PETG (Polyethylene Terephthalate Glycol)

PETG combines the strengths of both PLA and ABS, making it a popular filament for a variety of applications.

Uses

- Food Containers: Because it’s food-safe, many people use PETG for making food storage solutions and utensils.

- Mechanical Parts: Its durability and flexibility make it suitable for functional parts that need to endure stress.

- Outdoor Applications: PETG’s UV resistance makes it an excellent choice for items exposed to sunlight.

Considerations

PETG is easier to print than ABS but can be prone to stringing. You might need to adjust your print settings a bit to avoid those pesky strands in your prints.

4. TPU (Thermoplastic Polyurethane)

If flexibility is what you’re after, then TPU is your go-to filament. Known for its rubber-like qualities, it’s incredibly versatile.

Uses

- Wearable Items: From phone cases to custom shoes, TPU is great for designs that benefit from elasticity.

- Gaskets and Seals: Its softness and flexibility make it suitable for creating snug seals.

- Custom Toys: Many people use TPU to make soft, squishy toys that are safe for children.

Considerations

Printing with TPU requires careful setup; it may need a direct drive extruder for best results. Also, it’s worth noting that printing speed should be kept low to avoid jams or issues.

5. Nylon

Nylon is another high-performance filament that offers exceptional strength and durability. It’s able to withstand a good amount of stress, which makes it ideal for functional applications.

Uses

- Mechanical Parts: Perfect for gears, bearings, and other components that require high strength.

- Structure Components: Nylon can be used in structures that require flexibility and toughness.

- Textiles: It can even be used to create semi-flexible items like fabric and ropes.

Considerations

Nylon can absorb moisture from the air, affecting its printability and the quality of the final print. It also requires higher print temperatures and is best suited for those with some experience.

In Summary

Each type of 3D filament has its own set of strengths and weaknesses, making it crucial to choose the right one for your specific needs. Whether you prioritize ease of use, durability, or flexibility, there’s a filament that matches your project perfectly. As you explore the possibilities of 3D printing, allow your creativity to guide you in selecting the material that will bring your ideas to life. Happy printing!