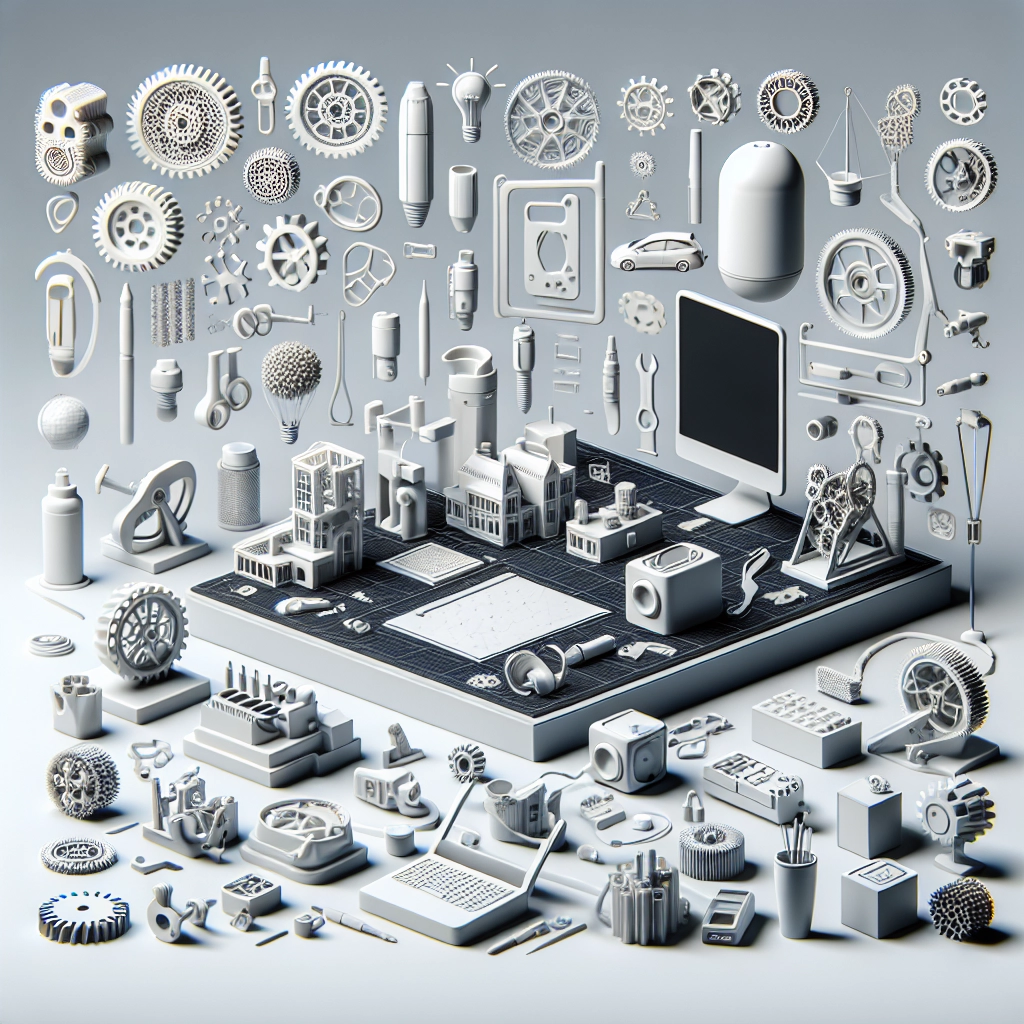

Creating Functional Prototypes with 3D Printing

In the world of design and innovation, the phrase "fail fast, learn quickly" reigns supreme. This radical approach encourages designers and engineers to get their ideas off the drawing board and into the real world as quickly as possible. One of the tools that has revolutionized this prototyping process is 3D printing. As we dive into this exciting topic, the potential of 3D printing to create functional prototypes will become clear, along with tips on making the most out of this technology.

The Power of Prototyping

Prototyping is a crucial step in any design process. It allows creators to visualize their ideas, identify potential flaws, and make necessary adjustments before committing to full-scale production. Traditionally, prototyping could be a time-consuming and expensive endeavor, often requiring specialized tools and materials. Enter 3D printing, which has dramatically reduced both the cost and time involved in prototyping.

The beauty of 3D printing lies in its ability to convert digital models into tangible objects quickly. Designers can experiment with different shapes, sizes, and features without the overhead of traditional manufacturing techniques. From automotive parts to intricate medical devices, the flexibility of 3D printing makes it an invaluable resource across various industries.

How to Create Functional Prototypes with 3D Printing

Step 1: Design Your Model

Before you can print anything, you need to have a digital model ready to go. Software like Fusion 360, SolidWorks, or even free options like TinkerCAD can help you draft your 3D model. Pay attention to the specific features you want to test; functional prototypes should incorporate the core mechanics or usability elements of the final product. You don’t need to design something perfect—being able to iterate is part of the prototyping process.

Step 2: Choose the Right Material

Once you have your design, it’s time to select the material for your prototype. Different 3D printing technologies use various materials, each with unique properties. For example, if you need something lightweight but sturdy, consider using PLA or PETG filaments. If your prototype must withstand higher temperatures or mechanical stress, materials like ABS or nylon are more suitable.

The choice of material can significantly impact the functionality of your prototype, so think carefully about what you need in terms of durability, flexibility, or even transparency, depending on your application’s needs.

Step 3: Print Your Prototype

With your model designed and the right material selected, it’s time to hit print! You can either purchase a 3D printer and do it yourself or utilize a service that specializes in 3D printing. If you’re using a service, be sure to provide them with clear instructions and specifications. Many online services allow you to upload your model, choose your materials, and will have it shipped directly to you.

During the printing process, keep an eye out for common issues such as warping or layer separation, especially if it’s your first time with a specific material. Familiarizing yourself with your printer’s quirks can save you a lot of headache.

Step 4: Test and Iterate

Once you have your prototype, it’s time to put it through its paces. Testing is where the magic happens. This stage can involve physical stress tests, usability studies, or even getting feedback from users. Document how the prototype performs, noting any discrepancies between your expectations and real-world results.

Often, you may find that you’ll need to make tweaks to your design after testing. That’s perfectly okay! The objective of prototyping is to refine your idea until it meets your goals.

Step 5: Repeat

The key to functional prototyping is iteration. Don’t be discouraged if your first prototype doesn’t hit the mark—each version should bring you closer to the final product. The adaptability of 3D printing means you can continuously tweak and improve your designs with rapid turnaround times.

A Bright Future Ahead

As 3D printing technology continues to evolve, the possibilities for functional prototypes are expanding. From speedier print times to innovative materials that mimic the properties of metals and plastics, the future looks bright. Whether you’re a seasoned engineer or a hobbyist tinkering away in your garage, embracing the power of 3D printing can help you transform your ideas into reality.

So why not take the leap? Dive into the world of 3D printing, and experience firsthand how creating functional prototypes can streamline your creative process and propel your projects to great heights. With the right tools, materials, and mindset, the only limit is your imagination. Let’s get printing!