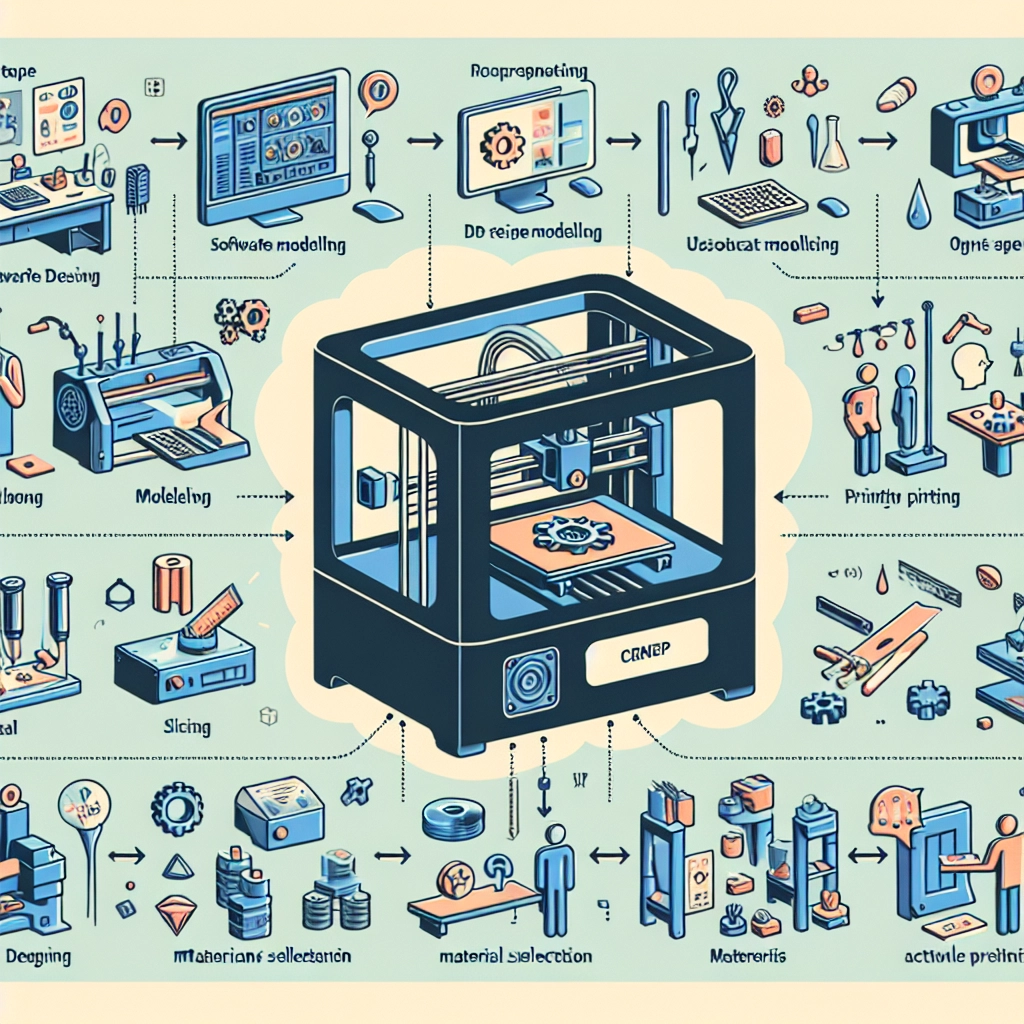

Designing for 3D Printing: Best Practices

As 3D printing becomes an integral part of industries from prototyping to bespoke manufacturing, understanding how to design specifically for this technology is crucial. While it offers fantastic opportunities for creativity and innovation, there are unique constraints and possibilities that come into play. So, whether you’re a veteran designer or a curious newbie, let’s explore some essential best practices to keep in mind when crafting for 3D printing.

Know Your 3D Printer

First and foremost, it’s vital to understand the capabilities and limitations of the 3D printer you’ll be using. Different printers use various technologies (such as FDM, SLA, or SLS) and materials, each with unique specifications. For instance, Fused Deposition Modeling (FDM) printers often require larger clearances and may not handle intricate details as well as SLA or resin-based printers. Familiarize yourself with the printer’s layer height, minimum feature size, and material properties. What might look amazing on paper could end up a frustrating print if you overlook these details.

Design for Support Structures

When designing for 3D printing, you must consider whether parts will need supports during printing. Overhangs greater than 45 degrees typically require additional support, which can be troublesome to remove later on. To mitigate this, design your parts with fewer overhangs or create supports that are easier to remove. Alternatively, you can leverage the slicing software to generate supports automatically, but knowing where they’ll apply and visualizing them in your design can save you time and resources.

Consider Orientation and Layering

The orientation of your model during printing has a massive impact on strength, surface quality, and even print time. Often, the best orientation for a piece isn’t the one that seems most intuitive. Spend some time experimenting with different orientations in your design software or slicing programs. It’s not just about aesthetics; certain orientations can take advantage of the layering process to bolster the structural strength of a print.

Tolerances Matter

When designing for 3D printing, always keep tolerances in mind. Parts that fit snugly or interlock often require adjustments, particularly with materials that might expand or contract during the printing process. A safe bet is to schedule some tolerances into your design, especially for moving parts or assemblies. Generally, around 0.2mm can provide a good balance for most prints, but it’s best to run a few tests to see how specific materials and printers behave.

Optimize Geometry for 3D Printability

The geometric constraints of 3D printing mean not all beautiful designs can be printed effectively. Avoid complex, thin walls or intricate internal structures that can’t be printed. Keeping your geometry simple and functional is crucial. Design with the 3D printing process in mind, opting for features that are easily printable while still achieving the visual or functional outcome you desire.

Use the Right Design Software

Choosing the right design software can also profoundly impact your 3D printing experience. Software like Fusion 360, TinkerCAD, or Blender offer functionalities tailored for 3D printing. Moreover, many of these platforms allow you to export models in various formats, giving you flexibility for different printers. Familiarity with the tools available can enhance your productivity and make the design process smoother.

Test, Test, Test

Finally, don’t forget the importance of prototyping extensively. Even with careful planning and design, nothing beats the insights gained from actual prints. Don’t hesitate to make small test versions of your design or even individual parts to see how they turn out. This step can lead to valuable lessons about materials, adherence, and overall print quality.

Designing for 3D printing is a journey that combines creativity with technical know-how. By following best practices and keeping the nuances of specific printers and materials in mind, you can reduce frustrations and increase the chances of a successful print. So, whether you’re creating a functional prototype or a stunning art piece, remember that experimentation is key, and every print is a learning opportunity. Embrace the process, and happy printing!