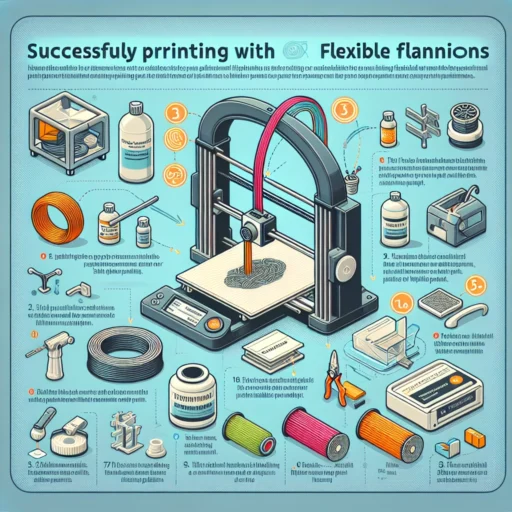

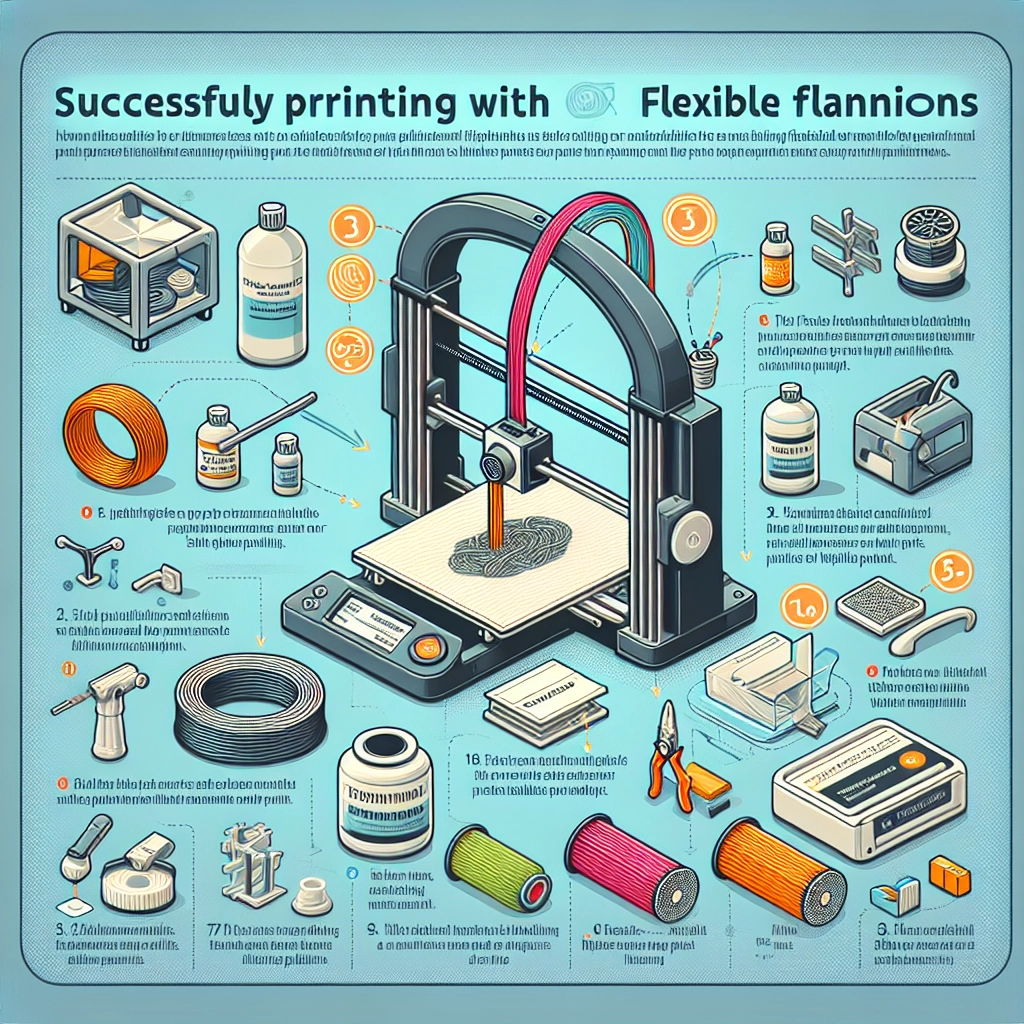

How to Successfully Print with Flexible Filaments

If you’ve dipped your toes into the wonderful world of 3D printing, you’ve probably heard some buzz about flexible filaments. They sound like a lot of fun, right? Imagine creating items that can bend and stretch—like phone cases, toys, or even custom-fit wearable tech! However, getting the perfect print with these materials can be a bit tricky. Don’t fret, though! With a little knowledge and patience, you can master the art of printing with flexible filaments.

Understanding Flexible Filaments

Flexible filaments, such as TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer), offer a unique set of properties. They combine the robustness of standard filaments with the pliability you’d associate with rubber or silicone. This means that the final products are not only durable but also have some elasticity. Whether you’re printing grippy handles or custom gaskets, the possibilities are limitless!

Choosing the Right Printer Settings

One of the most significant challenges when printing with flexible filaments is ensuring your settings are just right. Here are some key parameters to focus on:

-

Temperature Settings: Start by checking the manufacturer’s recommendations for print temperature. Most flexible filaments print well at temperatures between 210°C and 250°C, but you’ll want to experiment. If you notice stringing or a loss of shape, try adjusting the temperature incrementally.

-

Print Speed: Slower is usually better with flexible filaments. Speeds of around 20-30 mm/s often produce the best results. Quick movements can lead to issues like under-extrusion or poor adhesion.

-

Retraction Settings: Flexible materials are prone to oozing, which can create messy prints. Keep retraction distances short (around 1-3 mm) and set the speed low. This helps reduce stringing without creating pressure build-up in the extruder.

-

Layer Height: A layer height of 0.1 to 0.2 mm is typical for flexible filaments. Thinner layers can help with detail and surface quality, so feel free to experiment a bit here.

Choosing the Right Printer

Not all 3D printers are ready to handle flexible filaments effectively. Here are a few features to look for in your machine:

-

Direct Drive Extruders: Printers with direct drive extruders pull the filament directly from the spool into the hot end, making them more suitable for flexible materials. If your printer has a Bowden setup, consider upgrading or modifying your extruder system.

-

Good Cooling: Flexible filaments benefit from adequate cooling, as this helps maintain the shape during printing. Make sure your printer has a reliable cooling fan, and consider adding auxiliary cooling if necessary.

Preparing Your Build Surface

Another important aspect of printing with flexible materials is the build surface. A good adhesion prevents warping and helps your prints stick well during the process.

-

Choose the Right Surface: Glass, PEI sheets, or even blue painter’s tape can work well for flexible filaments. Using a layer of glue stick or hairspray can also help enhance adhesion.

-

Level Your Bed: A level bed is crucial. If your nozzle is too far from the build plate, you risk ruining your print before it even starts. Spend some time leveling your bed, and don’t hesitate to check it before every print.

Post-Processing and Finishing Touches

Once you’ve successfully printed your flexible object, a few finishing touches can elevate it even further:

-

Cleaning Up: Remove any excess material, like strings or artifacts, using scissors or a craft knife. Just be careful not to damage your print.

-

Testing Flexibility: Make sure to flex your printed object gently. This will give you a feel for its properties. If it feels brittle or doesn’t flex well, you might need to tweak your settings in future prints.

-

Storing Your Filament: Flexible filaments can absorb humidity, which can affect print quality. Store your filament in airtight containers with desiccants to keep them dry and ready for the next print.

Successfully printing with flexible filaments is both a challenge and a rewarding experience. While it may take a few attempts to nail down the perfect settings for your specific printer and use case, the versatility you gain from being able to create flexible, durable items makes it all worthwhile. So roll up your sleeves, adjust those settings, and let your creativity flow! With a little patience, you’ll be turning ideas into tangible projects in no time. Happy printing!