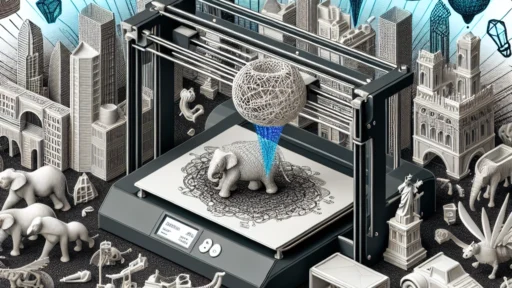

Advanced 3D Printing Techniques for Experienced Users

For those of you who have dipped your toes into the fascinating world of 3D printing, you’re likely familiar with the basics—selecting the right filament, calibrating your printer, and navigating slicing software. But as you progress and seek to push the boundaries of what you can create, advanced techniques become your best friends. Let’s dive into some of these methods that can elevate your 3D printing game!

Multi-material Printing

Imagine creating complex models that incorporate different materials—think rubbery parts alongside rigid structures! Multi-material 3D printing allows you to combine multiple types of filaments into a single print, providing enhanced functionality and aesthetics.

To get started, you might want to invest in a printer equipped with a multi-material upgrade (MMU). Brands like Prusa and Bamboo Labs offer kits that let you load several filaments simultaneously. While the initial setup can be intricate, the results are absolutely worth it. You can create items like flexible joints in toys or even prototypes that mimic the final product closely with varying colors and textures.

Advanced Slicing Techniques

You may already be familiar with slicing software, but have you explored its full potential? Advanced slicing settings can greatly enhance the strength, appearance, and effectiveness of your prints. For instance, playing with infill patterns, layer heights, and wall thickness can dramatically affect how your design looks and functions.

Consider experimenting with adaptive layer height, which allows for different layer resolutions depending on the complexity of the model. This not only saves filament but also reduces print time while ensuring finer details come out crisp and clear. Infill settings can also be optimized; using settings like Gyroid or Honeycomb can provide a good balance between strength and material usage.

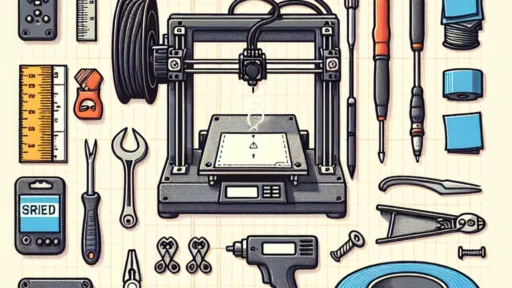

Post-Processing Techniques

Once your print is finished, it’s not game over—post-processing can be the key to achieving those stunning, polished finishes. Techniques like sanding, painting, or applying chemical smoothing can transform your printed design from ‘okay’ to ‘wow’!

For instance, you can use a simple fine-grit sandpaper to smooth out rough edges or layer lines. If you prefer a more advanced approach, consider vapor smoothing with acetone for ABS prints, or using a resin dip for PLA to achieve a glossy finish. Don’t forget about priming and painting; with a little patience and practice, a perfect paint job can make your print look professional.

Toolpath Manipulation

For those really looking to get advanced, manipulating toolpaths can give rise to unique geometries and improved strength. Using dual extrusion or consideration of deposition strategies can yield prints with less stress concentrate. If you have a specific design in mind, tweaking the toolpath can provide you with enhanced performance properties in critical areas of your model.

Software like Fusion 360 allows for custom toolpath design, so if you’re already comfortable with design software, this can be an exciting avenue to explore. Ultimately, this technique might require a bit of understanding in CAD, but the possibilities it brings are endless.

Integrating Electronics and Mechanisms

As 3D printing technology evolves, so does its integration with electronics. Why not happen to create something that lights up or moves? Incorporating LEDs, sensors, or motors into your prints allows for exciting projects like interactive models or even custom robots.

Consider researching basic circuit design or using platforms like Arduino. With a little know-how, you can integrate these components seamlessly into your prints, creating functional and fun projects. Just remember, careful planning during the design phase will save you headaches later on.

Going Beyond with Advanced Materials

As an experienced user, you may wish to experiment with specialty filaments, such as carbon fiber-infused or flexible TPU. Each material brings unique properties that can lead to impressive results. For instance, carbon fiber can create exceptionally strong and lightweight parts, while TPU can allow for flexibility.

When diving into these advanced materials, familiarize yourself with their specific printing requirements, including nozzle sizing and temperature settings. It might be a challenge initially, but the enhanced performance and versatility they offer can truly take your projects to the next level.

Embrace the Adventure

As you navigate through these advanced techniques, keep in mind that experimentation is part of the journey. Don’t shy away from making mistakes; each misstep is a learning opportunity that will only refine your skills further. Whether you’re creating functional prototypes, intricate designs, or innovative pairs of parts, the world of advanced 3D printing is vast and full of possibilities.

So, challenge yourself, share your findings, and connect with the ever-growing maker community. Together, let’s see just how far we can take this incredible technology! Happy printing!