Getting Started with Multi-Material 3D Printing

If you’ve been following the dazzling world of 3D printing, you’ve likely stumbled upon the term "multi-material 3D printing." Sounds fancy, doesn’t it? But what does it really mean, and how can you get started with it? Let’s dive in!

What is Multi-Material 3D Printing?

At its core, multi-material 3D printing refers to the process of using multiple types of materials in a single print job—think of it as creating a more colorful and functional masterpiece! Instead of being limited to one filament (like the common PLA or ABS), you can combine various materials, each with different properties.

Why is this useful? Well, imagine printing a phone case that’s not only sturdy but also has some flexible parts for grip. Or crafting a prototype that combines rigid and soft elements, like a housing with buttons that need flexibility. The possibilities are practically endless!

Types of Multi-Material Printing

There are a few different methods for achieving multi-material 3D prints, each with its own strengths:

-

Fused Deposition Modeling (FDM)

This is the most common type for home users and small businesses. Here, two or more extruders come into play. Each extruder heats a different filament and lays it down layer by layer. Your printer will work its magic to switch materials at the right time.

-

PolyJet Printing

Often used for more professional applications, PolyJet technology uses droplets of photopolymer resin that are cured by UV light, allowing for incredibly high detail. This method can even layer different materials within a single print job, meaning you can mix rigid and flexible materials or even color them differently.

-

Binder Jetting

While less common for personal users, binder jetting involves using a binder material that selectively binds powder particles to form a solid part. This method can incorporate different materials, which makes it suitable for industrial applications.

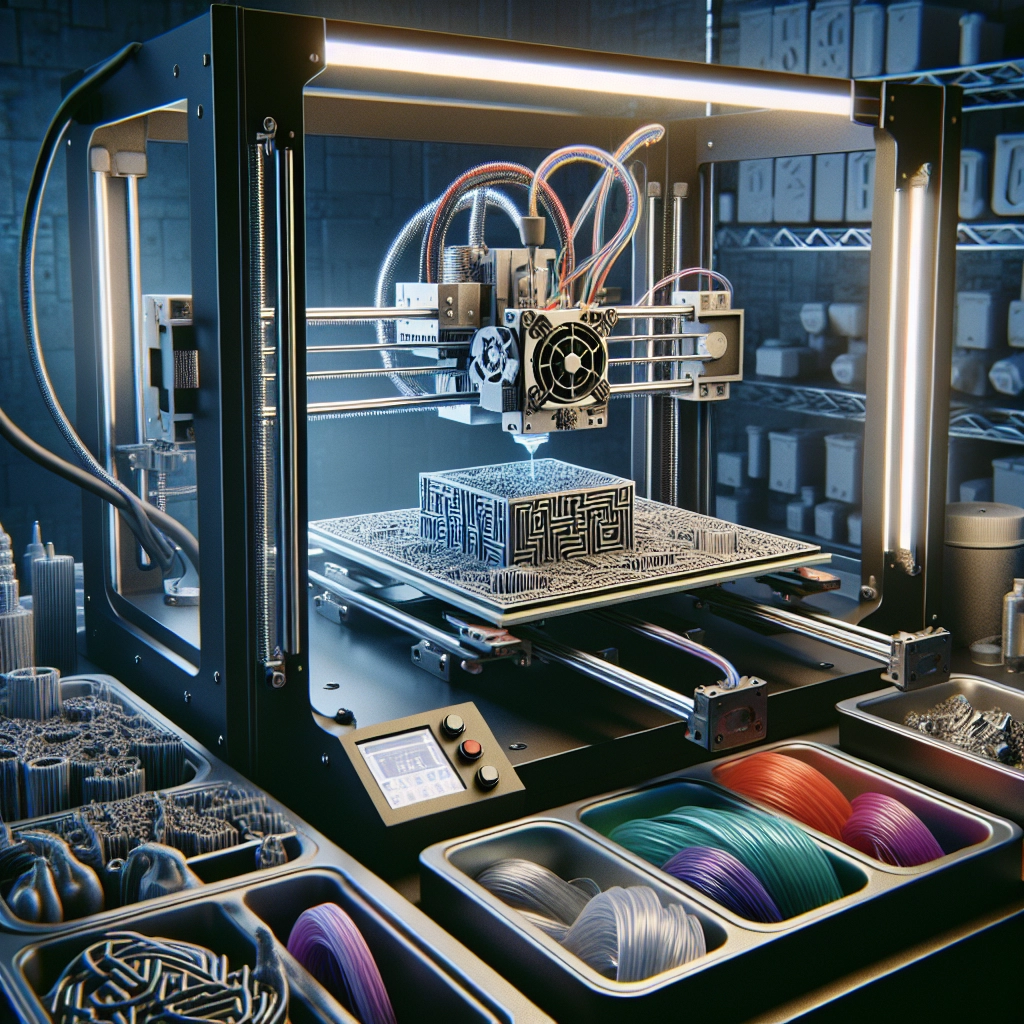

Essential Gear and Setup

To launch into the world of multi-material printing, you’ll need a few essential tools and setups:

1. The Right Printer

Not all 3D printers can handle multiple materials. If you’re considering multi-material printing, look for printers with dual extrusion capabilities. Brands like Prusa, Ultimaker, and MakerBot offer great options.

2. Compatible Materials

You’ll also need an array of filaments that work well together. For FDM printers, many people opt for PLA, PETG, or TPU filaments. It’s essential to ensure that the materials you choose can adhere to each other well and don’t warp or degrade during printing.

3. Slicing Software

Slicing software plays a pivotal role in multi-material 3D printing. Programs like Cura or Simplify3D allow you to designate which extruder will lay down which material, and they will help optimize settings for the best outcome.

Best Practices for Multi-Material Printing

To help ensure a successful print, here are a few handy tips:

-

Calibration is Key: Always calibrate your printer before starting a multi-material project. Each material may require different nozzle temperatures and settings, so precision is imperative.

-

Test Prints: Start with small test prints to find the optimal temperatures, speeds, and adhesion properties. This practice will save you a lot of frustration down the line.

-

Consider Supports: Depending on your design, you may need to include supports, especially for complex geometries. Make sure your slicing software can handle support for each material properly.

-

Design for Compatibility: When creating models, consider how different materials will work together. For example, a hard shell with a flexible button will need to be designed with precise tolerance to function well.

Where to Find Inspiration

The internet is teeming with resources for multi-material printing! Check out community forums, YouTube channels dedicated to 3D printing, or sites like Thingiverse for stunning models that make use of multiple materials. You might just discover your next project!

Exploring the realm of multi-material 3D printing can be a thrilling journey, opening doors to endless creativity. With the right tools, a bit of practice, and some adventurous spirit, you’ll be on your way to crafting exciting projects that boast a variety of textures, colors, and functionalities. So, roll up your sleeves, bring out that printer, and start playing with imagination! Who knows what amazing things you’ll create?