The Integrative Future of 3D Printing and Manufacturing

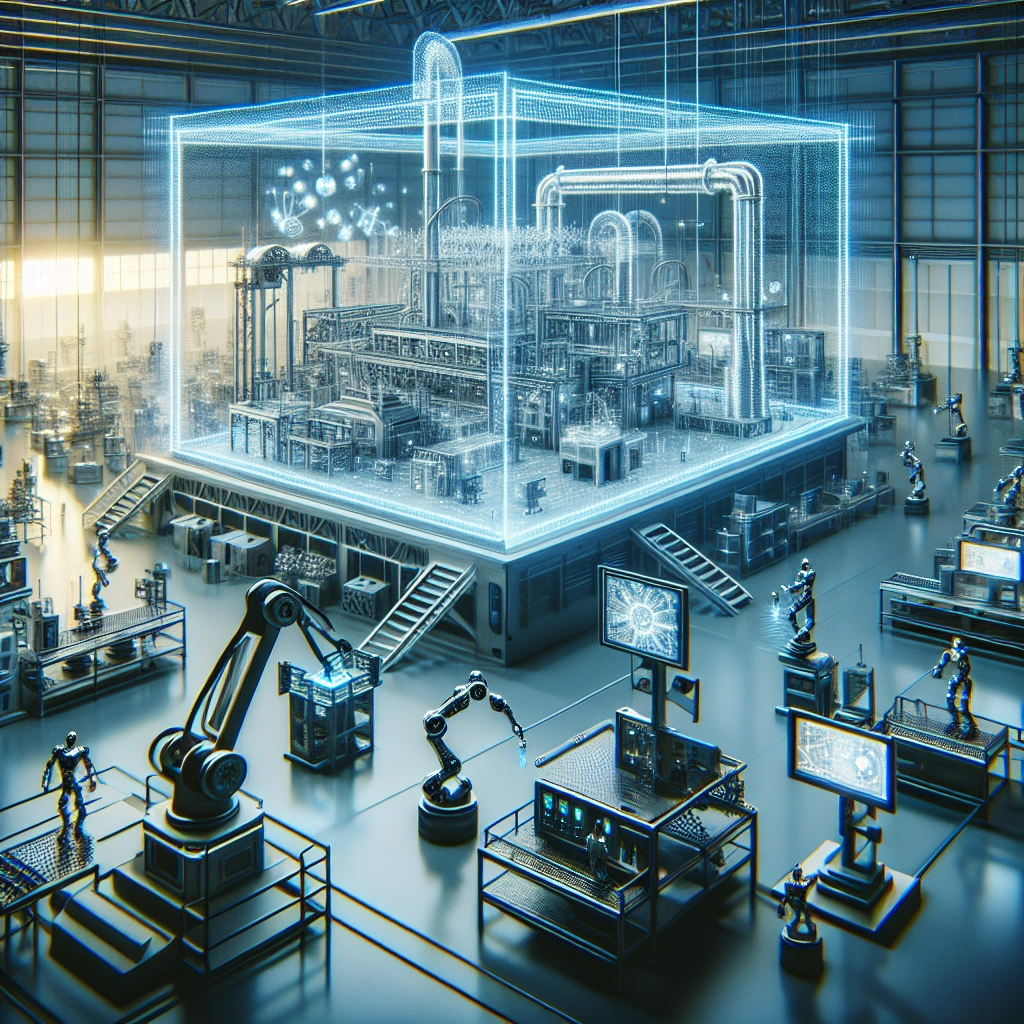

Imagine a world where the lines between design, production, and logistics blur into one seamless process. Welcome to the future of manufacturing, where 3D printing isn’t just a trend but a transformative force reshaping the entire landscape. This revolutionary technology blends creativity with practicality, and its integration into traditional manufacturing practices is set to redefine the way we think about production.

A Brief Snapshot of 3D Printing

3D printing, or additive manufacturing, has come a long way since its inception in the 1980s. Initially relegated to the realm of prototyping, this technology has evolved dramatically, making it possible to create finished products on demand. Using digital designs, 3D printers build objects layer by layer from materials like plastics, metals, and even biological substances. The result? A highly customizable production process that can cater to specific needs and reduce waste—talk about efficiency!

Bridging the Gap Between Design and Production

Traditionally, manufacturing involves different stages: design, prototyping, production, and distribution. Each of these stages can be silos, with potential delays and communication issues spread across departments. Here’s where 3D printing steps in to change the game. With integrated software solutions, designers can quickly transition from a digital concept directly into a physical product, effectively collapsing the timeline between ideation and realization.

For instance, companies like Nike and Adidas are already tapping into this advantage. They utilize 3D printing to produce unique shoe designs tailored to individual customer needs. Imagine being able to customize your footwear based on your favorite colors, patterns, or even specific ergonomic features—all thanks to an efficient, integrated 3D printing system.

Mass Customization: The New Normal

The future of 3D printing doesn’t just stop at bridging design and production; it opens doors to the era of mass customization. Do you remember the days when customization meant choosing between a few colors or styles? Those days are gone. Today, consumers value personalization and uniqueness, and 3D printing caters to that demand beautifully.

One great example is the healthcare industry, where 3D printing is revolutionizing the way medical devices are produced. Surgeons can now print patient-specific implants and prosthetics that fit perfectly, improving outcomes and reducing recovery times. Instead of relying on a "one size fits all" approach, tailored solutions become a viable standard, leading to better patient care and satisfaction.

Sustainability at Its Core

Integrating 3D printing into manufacturing also paves the way for sustainable practices. Traditional manufacturing methods often involve substantial waste generation and high energy consumption. In contrast, 3D printing minimizes waste by only using the necessary material to create the desired object, reducing the environmental footprint significantly.

Companies are increasingly adopting biocompatible and recycled materials in their 3D printing processes, enhancing their sustainability efforts. Take, for example, the use of recycled plastics in the production of consumer goods. As society becomes increasingly conscious of environmental impact, businesses leveraging 3D printing can align themselves with eco-friendly values, appealing to a growing market of sustainable consumers.

Challenges on the Horizon

While the potential of an integrative future powered by 3D printing is exciting, it’s essential to address some challenges. One major hurdle is the need for skilled labor. As companies adopt more sophisticated 3D printing techniques, workers must be trained in both the technology and its intricacies.

Another challenge lies in regulatory frameworks. In industries like healthcare and aviation, ensuring safety and compliance remains a top priority. Manufacturers will need to navigate complex regulations while ensuring their 3D-printed products meet necessary quality standards.

The Future is Collaborative and Adaptive

As we look ahead, the integration of 3D printing and manufacturing will undoubtedly lead to more collaborative environments. Engineers, designers, and manufacturers will need to work closely together, pushing the boundaries of creativity and functionality. The 3D printing technology is not just a tool; it’s a catalyst for innovation.

In a world that’s constantly evolving, the synergy between 3D printing and traditional manufacturing ignites a spark for new possibilities. From optimizing products for individual consumers to creating eco-friendly solutions, the future appears brighter than ever. Ultimately, it’s not just about what can be made but how we can make things more sustainable, personalized, and efficient as we move forward. The journey is just beginning, and it’s one we’ll all be a part of.