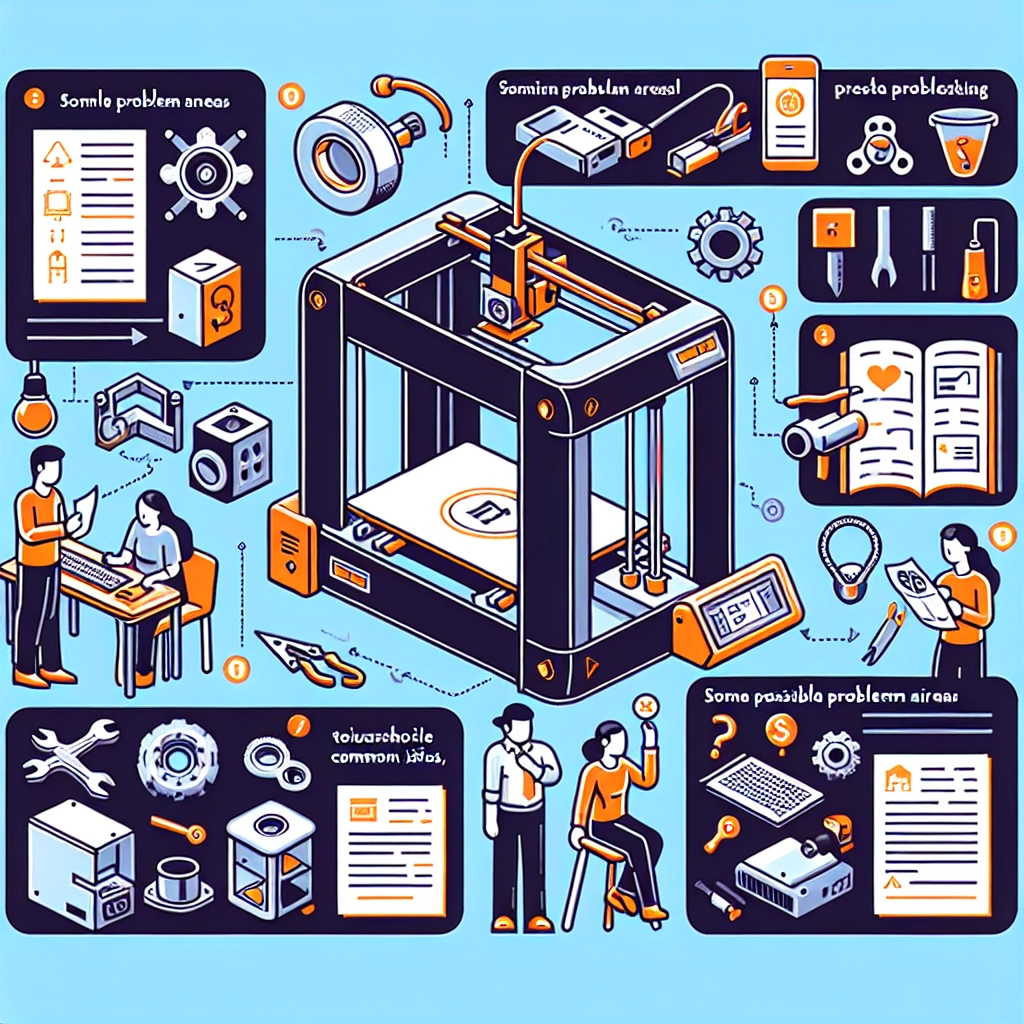

Troubleshooting Common Issues in 3D Printing

Welcome to the fascinating world of 3D printing! Whether you’re a seasoned pro or just starting your journey into this innovative field, it’s not uncommon to run into a few bumps along the way. The beauty of 3D printing lies not just in the creation process, but also in the learning journey — each misstep can teach us something new. So, let’s deep dive into some common issues you might face while 3D printing and how you can easily troubleshoot them!

1. Warping

One of the most notorious problems in 3D printing is warping. This typically occurs when the corners of your print begin to lift from the print bed as it cools, leading to an uneven or unusable print.

Solutions:

- Heat it up: Ensure your print bed is heated to the right temperature for the filament you’re using (usually around 60°C for PLA, 100°C for ABS).

- Use a raft: Adding a raft in your print settings can create a stable base that helps minimize warping.

- Bed adhesion: Consider using glue stick, hairspray, or specialty build surfaces to improve adhesion.

2. Under-Extrusion

Under-extrusion happens when your printer doesn’t extrude enough filament during the print, leading to gaps and weak structures. This issue can be frustrating, especially when you’re aiming for that perfect finish!

Solutions:

- Check the nozzle: Clogged or partially blocked nozzles can restrict the flow of filament. Make sure to clean it regularly.

- Filament quality: Sometimes the filament itself may be the problem. Ensure that you’re using high-quality filament—cheap alternatives may lead to more problems.

- Adjust settings: Review your slicer settings for the extrusion multiplier; increasing this can help if you notice consistent under-extrusion.

3. Stringing

Have you ever finished a print only to find fine strings and wisps of filament all over your model? Yup, that’s stringing, and it can make your beautiful prints look messy.

Solutions:

- Retraction settings: Adjust the retraction distance and speed in your slicer settings. Increasing retraction distance can help reduce stringing.

- Temperature tweak: Lowering the printing temperature can also minimize oozing. When filament is too hot, it becomes more runny and prone to stringing.

- Final pass: If you still notice some strings, consider using a heat gun or a lighter, carefully, to remove them after printing.

4. Layer Separation

This issue can be disheartening. You may notice layers of your print beginning to separate or delaminate. This weakness can compromise your model’s integrity and functionality.

Solutions:

- Check temperature: Ensure that your printing temperature is hot enough for the filament you’re using. If it’s too low, layers won’t bond well.

- Printing speed: Slowing down the print speed can give each layer more time to adhere before the next one is laid down.

- Filament quality: Consistently high-quality filament can prevent this issue from arising in the first place.

5. Nozzle Clogs

Ah, the dreaded nozzle clog! If you find your printer is just not extruding anymore, it could be time to check for a clog. This is particularly likely after lengthy prints or if you’ve switched filaments without cleaning your nozzle.

Solutions:

- Cold pull: Performing a cold pull with your filament can often clear minor clogs pretty easily. Essentially, you heat up the nozzle, then pull the filament out slowly to take any debris with it.

- Nozzle cleaning: Utilize a needle or small drill bit designed for unclogging nozzles if necessary. For persistent issues, consider replacing the nozzle entirely.

6. Over-Extrusion

While under-extrusion leaves gaps, over-extrusion can create unsightly blobs and a bulging print. It’s vital to find that happy medium!

Solutions:

- Recalibrate your steps-per-mm: Ensure your extruder calibration is accurate. A discrepancy here can lead to too much filament being fed.

- Adjust flow rate settings: Reducing the flow rate in your slicer can alleviate the issue, helping to balance things out for cleaner prints.

3D printing is about experimenting and adjusting. Each machine behaves a little differently and might require a unique approach. Don’t get discouraged by these common issues; instead, view each challenge as a stepping stone to becoming a better 3D printer.

As you tackle these issues one by one, you’ll likely build not only your skill set but also your confidence in this incredible form of technology. Happy printing!