The Future of 3D Printing: Trends to Watch

3D printing has come a long way since its inception. What started as a niche technology for prototyping and hobbyists has blossomed into a major player across various industries, from healthcare to aerospace. As we step deeper into the 21st century, the potential for 3D printing continues to expand, opening up exciting possibilities that could reshape how we create, manufacture, and think about products. So, what trends should we keep an eye on as we forge ahead into this dynamic landscape? Let’s dive in!

Customization at Its Best

One of the most remarkable features of 3D printing is its ability to create highly customizable products. Whether it’s tailored medical implants or personalized sneakers, consumers are increasingly demanding items that fit their unique needs and preferences. In the future, we can expect to see more companies adopting mass customization strategies, enabling them to produce personalized goods on a large scale. Imagine walking into a shoe store, having your foot scanned, and then receiving a pair of shoes that perfectly fits your feet—all made right there on-site.

Sustainability Takes Center Stage

As environmental concerns rise, industries are actively seeking sustainable alternatives to traditional manufacturing methods. 3D printing, with its potential to minimize waste, is positioned as a leading contender in this shift. The technology allows for the use of biodegradable materials and offers opportunities to recycle existing products into new ones. We’re already starting to see companies experiment with bio-based filaments made from plant materials. As more industries adopt these practices, we can anticipate a future where sustainability is not merely an afterthought but the foundation of production.

The Rise of Bioprinting

One of the most groundbreaking applications of 3D printing is in bioprinting, which refers to the addition of biological materials and living cells into the printing process. This technology could revolutionize healthcare by enabling the creation of tissues and perhaps even organs for transplantation. Researchers are already making strides in this area, with lab-grown tissues being developed for drug testing and eventually, for patient-specific transplants. As we move forward, the advancements in bioprinting could change the way we approach medical treatment altogether—imagine a world where organ rejection might become a thing of the past!

Advancements in Materials

The capabilities of 3D printing hinge not only on the technology itself but also on the materials used. In the near future, we can expect an exciting expansion of materials suitable for 3D printing, including metals, ceramics, and advanced composites. Metal 3D printing, for example, is already gaining traction in aerospace and automotive sectors due to its strength and lightweight properties. The versatility of new materials will open doors for innovative applications, ensuring that 3D printing remains at the forefront of industrial progress.

Integration with AI and Automation

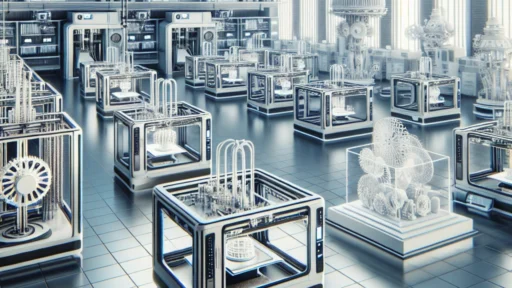

Additive manufacturing isn’t an isolated process anymore. The integration of artificial intelligence (AI) and automation into 3D printing workflows holds immense potential. AI can enhance design processes, analyze data from prints, and even predict failures before they happen. Meanwhile, automated systems can speed up production and maintain consistency across multiple items. This fusion of technologies could lead to faster and more efficient production lines, making 3D printing more competitive with traditional manufacturing methods.

Decentralization of Production

Another trend set to gain momentum is the decentralization of production. 3D printing allows for on-demand manufacturing, which means products can be produced close to where they are needed. This trend could reduce shipping costs and carbon emissions while also increasing responsiveness to market demands. Imagine communities producing what they need locally instead of relying on global supply chains—this could dramatically change economic landscapes and empower local economies.

Education and Skill Development

As 3D printing technologies evolve, so too will the skill sets required to operate them. Educational institutions are starting to incorporate 3D printing into their curriculums, preparing the next generation for careers in this field. Not just limited to engineering or design, these skills will be valuable in fields like medicine, architecture, and even social entrepreneurship. The more people understand and can utilize 3D printing, the more creative solutions we will see emerging.

As the future of 3D printing unfolds, we find ourselves at the intersection of creativity and technology, innovation and necessity. With each new breakthrough, we’re not just changing how we manufacture; we’re changing how we think about making things altogether. It’s a thrilling time to be involved in the world of 3D printing, and we can only imagine the remarkable possibilities that lie ahead. Whether it’s creating bespoke items that fit your lifestyle or advancing healthcare with bioprinting, the future looks bright, indeed!