Understanding the Science Behind 3D Printer Filaments

In our tech-savvy world, 3D printing has become more accessible and exciting than ever. Whether you’re a hobbyist crafting intricate models or a professional creating prototypes, the foundation of any 3D printing project lies in the filament you choose. But how much do you really know about the science behind these fascinating materials? Let’s dive into the nitty-gritty of 3D printer filaments and discover what makes them tick.

The Basics: What Are 3D Printer Filaments?

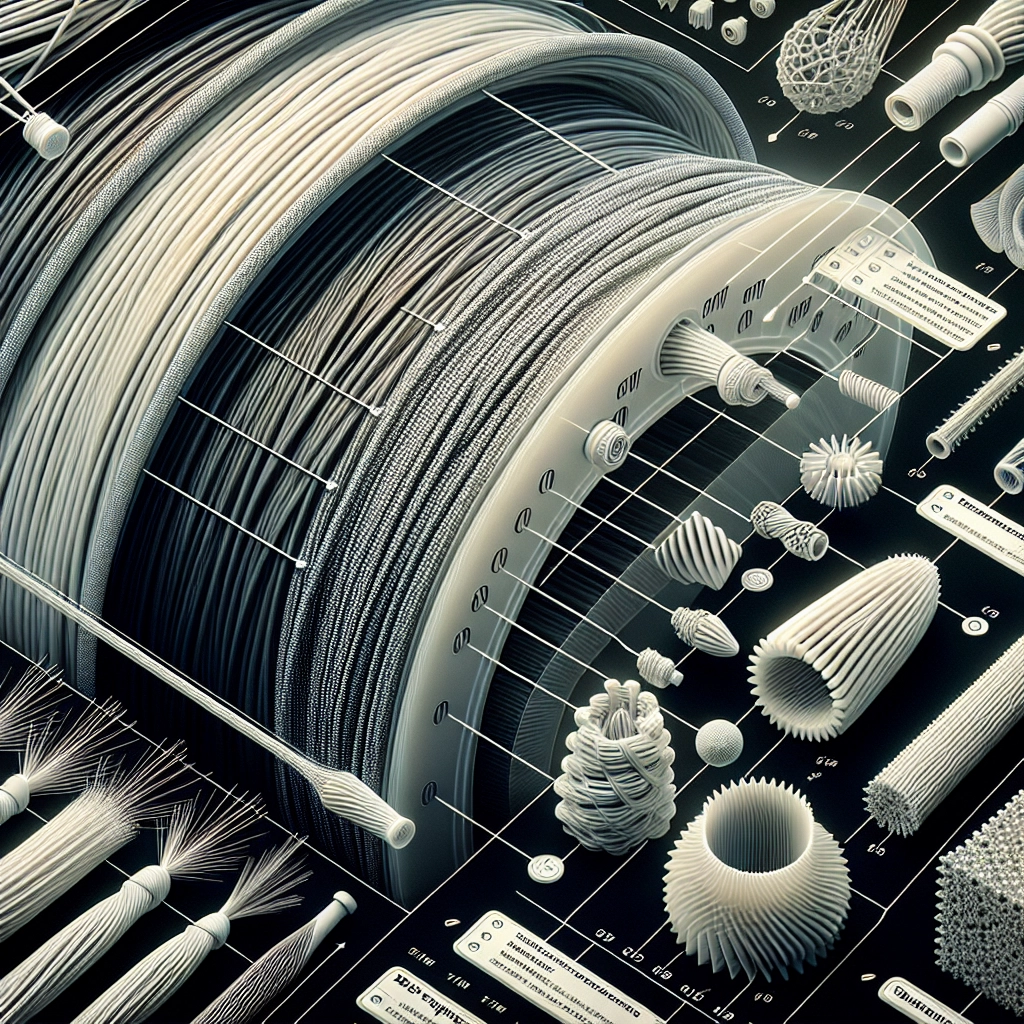

At its core, filament is the material that 3D printers extrude to create objects. Most common 3D printers use a process called Fused Deposition Modeling (FDM), where a filament is heated to its melting point and then deposited layer by layer to form a three-dimensional object. Filaments typically come in several types, each made from different materials that define their properties, uses, and printing experiences.

Types of Filaments

PLA (Polylactic Acid)

PLA is often the go-to filament for beginners. Made from renewable resources like corn starch or sugarcane, this eco-friendly option is relatively easy to print with. It has a lower melting temperature than other materials, meaning it doesn’t require a heated bed. Plus, it offers vibrant colors and a pleasing finish, making it perfect for detailed models and prototypes.

However, while PLA is great for indoor use, it has one significant drawback: heat sensitivity. If you leave a PLA creation in a hot car or near a heat source, it can warp. This makes it less viable for functional parts that might face temperature variations.

ABS (Acrylonitrile Butadiene Styrene)

Next up, we have ABS, a sturdier option favored by more experienced users. Known for its flexibility and impact resistance, ABS is the material you’ll often find in LEGO bricks and durable consumer products. It requires a heated bed to prevent warping during the printing process and produces a more pungent smell while printing compared to PLA.

Although ABS offers great durability, it can be a bit tricky to work with due to its tendency to warp and its need for higher temperatures. Proper ventilation is crucial during printing to mitigate the strong fumes.

PETG (Polyethylene Terephthalate Glycol-Modified)

PETG is like the best of both worlds for those who want the ease of PLA with some strength characteristics of ABS. It’s robust, flexible, and resistant to moisture, making it a popular choice for functional parts. Plus, it has excellent adhesion, which reduces the likelihood of warping.

This filament does introduce a slight learning curve, especially when it comes to printer settings. Still, its compatibility with various projects (from bottles to mechanical parts) makes it a reliable choice.

TPU (Thermoplastic Polyurethane)

If you’re looking for flexibility, TPU is the way to go! This rubber-like filament is ideal for creating items requiring elasticity, such as phone cases or wearable accessories. Because of its soft nature, printing TPU can be challenging, often requiring slower speeds and specific settings to ensure a successful print.

However, its unique properties can open up a world of creative possibilities for those willing to put in the extra effort!

Nylon

Nylon filaments bring a whole new level of durability and strength, making them perfect for functional prototypes, gears, or even certain automotive parts. The downside? Printing with nylon can be a hit or miss for beginners, as it typically needs specific temperature settings and is notorious for absorbing moisture from the air, which can affect print quality.

The Role of Additives

While the primary filament types cover the basics, many filaments on the market come infused with additives or blends to enhance properties. For example, some PLA filaments are infused with wood or metal particles, giving them a unique texture and look. Others might include glow-in-the-dark properties or flexibility enhancements.

These additives can give your projects a unique spin, but it’s wise to check compatibility and settings before diving into a new blend.

The Trends of Tomorrow

As 3D printing technology continues to evolve, so does the filament landscape. We’re seeing innovations such as biodegradable filaments, composites that can mimic metal or ceramic, and even filaments compatible with medical applications. This opens new avenues for creativity and practicality, transforming the way we think about production and design.

Understanding the science behind 3D printer filaments can take your projects from basic to extraordinary. No matter your experience level, knowing the strengths and weaknesses of each type can help you make the best choice for a striking result. Each filament tells its own story and opens a door to limitless possibilities—so why not explore them? After all, in the world of 3D printing, your imagination is the only limit!