The Role of 3D Printing in Manufacturing and Production

In a world that continually pushes the boundaries of innovation, 3D printing stands out as a true game-changer for manufacturing and production. If you haven’t been keeping up with the latest trends, you might still think of 3D printing as just a novelty or a hobby for tech enthusiasts. However, its transformative effect on industries is nothing short of revolutionary. So, let’s dive into how this technology is reshaping the landscape of manufacturing—impacting everything from design to distribution.

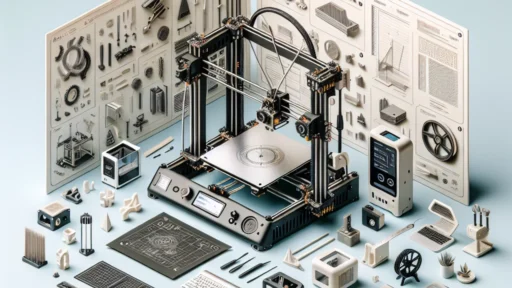

The Basics of 3D Printing

At its core, 3D printing, or additive manufacturing as it’s often called, is the process of creating three-dimensional objects from a digital file. Think of it like a very high-tech glue gun, building an object layer by layer. Instead of subtracting material (like traditional manufacturing methods), 3D printing adds material until the object is formed. This method can use various materials, ranging from plastics and metals to ceramics and food!

What’s particularly exciting about 3D printing is its flexibility and design freedom. Unlike traditional manufacturing processes like injection molding or machining, which can require significant setup time and are limited by the capabilities of the machinery, 3D printing allows for rapid prototyping and the creation of complex geometries that would be impossible to achieve otherwise.

Customization at Scale

One of the standout features of 3D printing is its ability to facilitate customization at scale. Imagine a healthcare provider that needs a tailor-made prosthetic limb or dental device. With traditional manufacturing, creating a customized solution can be not just time-consuming but also cost-prohibitive due to the complexities involved. 3D printing, however, enables rapid production of customized items without the need for extensive tooling.

This capability isn’t just confined to healthcare. The automotive and aerospace industries have also started utilizing 3D printing for bespoke parts. In these industries, where each milligram of weight can make a huge difference in fuel efficiency, manufacturers can produce lightweight, specialized components quickly and cost-effectively.

Reducing Waste

Environmental sustainability is a growing concern across all industries, and this is where 3D printing shines yet again. Traditional manufacturing processes often involve subtracting material, leading to significant waste. In contrast, 3D printing is inherently more materials-efficient, as it generates objects layer by layer, using only the necessary amount of material.

Moreover, on-demand production can reduce inventory waste—companies can produce parts only when they’re needed. This shift can significantly lower storage costs and reduce the carbon footprint associated with transporting goods around the globe.

Speeding Up Production

The speed at which products can go from concept to physical output is astonishing in the world of 3D printing. Designers can quickly iterate and test their creations in real time without lengthy delays. Prototyping becomes a breeze as teams can go through multiple iterations in mere days or even hours.

Even in more established manufacturing processes, 3D printing is being integrated into traditional workflows as a way to streamline production. By allowing for rapid prototyping, businesses can reduce their time to market dramatically, enabling them to stay one step ahead of their competitors.

Challenges and Future Outlook

Despite all the benefits, 3D printing does come with its challenges. Speed and cost can still be barriers, particularly for larger production runs. The technology is advancing rapidly, but not every industry has fully embraced it yet. There are also concerns regarding patenting and intellectual property, as the ease of replication can lead to potential violations.

However, as material science continues to evolve and printing techniques improve, the future of 3D printing in manufacturing looks incredibly promising. Industries are actively exploring innovative materials and techniques to solve existing challenges, while new applications are constantly emerging.

A Transformative Journey

As we reflect on the impact of 3D printing in manufacturing and production, it’s clear that it’s not just a passing trend. From optimizing supply chains to creating personalized solutions, the potential is enormous. While there are hurdles to overcome, the ongoing advancements in 3D technology are paving the way for a more efficient, sustainable, and customized future.

As we move forward, industries that embrace these innovations will undoubtedly find themselves at the forefront of not only technological advancement but also in revolutionizing how we think about production and design. After all, in a world increasingly driven by customization and sustainability, 3D printing isn’t just building objects—it’s building the future.