Understanding the Impact of Filament Density on 3D Prints

If you’re diving into the world of 3D printing, one term you often hear but might not fully grasp is “filament density.” It sounds technical, right? But understanding this concept is crucial for every maker, tinkerer, or budding inventor. Whether you’re crafting a miniature model or a larger functional part, filament density can significantly influence the quality, strength, and appearance of your prints. So, let’s break it down into bite-sized pieces!

What is Filament Density?

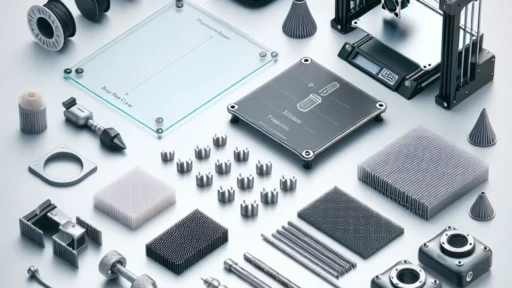

Simply put, filament density refers to the mass of a given volume of filament. It’s measured in grams per cubic centimeter (g/cm³). Different types of filament—like PLA, ABS, PETG, or TPU—have varying densities, which means that a certain length of each can weigh differently. For instance, a spool of PLA will typically be lighter than an equal volume of ABS because of its lower density.

When 3D printing, you might not think too much about density beyond selecting your material. However, it plays a substantial role in how your design turns out.

Why Does It Matter?

1. Strength and Durability

Filament density can directly impact the strength of your printed objects. Higher density materials, like nylon or PETG, often produce sturdier parts. This is great for functional items that need to withstand stress or wear and tear, like mechanical components or outdoor creations. Conversely, while lighter materials such as PLA might be easier to print and provide impressive detail, they may lack the toughness needed for more demanding applications.

2. Print Settings

Density influences not just the mechanical properties, but also how you approach printing settings. For example, if you’re working with a denser filament, you might need to tweak the nozzle temperature, bed adhesion, and layer height to yield the best results. A misunderstanding of density without corresponding adjustments might lead to under-extrusion or poor layer adhesion, resulting in a failed print—nobody wants that!

3. Cost Efficiency

Using denser filament can sometimes lead to more economical prints over time. Sure, the initial cost may be higher for quality materials, but if they result in more durable prints with fewer failures, you could save money in the long run. Think about it: fewer completed projects ending up in the recycling bin means less wastage and more creativity!

Wall Thickness and Infill Density

When you’re designing a model, keep in mind the interplay of wall thickness and infill density. Thicker walls provide more strength, but the choice of filament density can change how much infill you might need. For example, with a denser filament and thick walls, you might be able to use a lower infill percentage without sacrificing structural integrity. Conversely, for lighter filaments like PLA, you might need a higher infill percentage to achieve the same strength. It all comes down to striking a balance that caters to your specific project.

The Aesthetic Factor

Let’s not overlook the visual aspect of your prints! Filaments with varying densities can yield drastically different surface finishes and appearances. Denser materials often provide a glossy finish, while lighter materials tend to have a matte look. Depending on your project’s needs, you might choose a filament based not just on strength, but how it looks once printed. Fast-printed prototypes don’t always need to look perfect, whereas artistic models might demand something more visually appealing.

Experimentation is Key

The landscape of 3D printing is continually evolving, with new materials and blends hitting the market frequently. So, if you encounter a new filament type with a different density, don’t shy away from experimenting! Every printer and model can react differently to various filaments. Keep a keen eye on your settings as you go, and don’t be afraid to document your process.

In the 3D printing community, sharing experiences can help everyone grow, and who knows? Your findings might help someone else avoid a frustrating failure.

As we’ve explored, understanding filament density can significantly impact the types and quality of prints you create. From strength to aesthetics, each filament offers unique characteristics that can elevate your projects. Armed with this knowledge, you can make informed choices that not only boost your creativity but also enhance the durability of your prints. So, whether you’re crafting a fun decorative piece or a highly functional component, remember to take filament density into consideration. Happy printing!