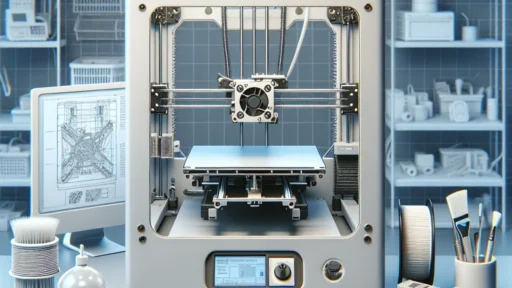

3D printing has revolutionized the way we think about manufacturing and creativity, rapidly moving from the realm of hobbyists to professional applications. Central to this innovation is the choice of filament material; each type comes with its own set of properties, advantages, and challenges. Three of the most popular filaments are PLA, ABS, and PETG. Whether you’re just starting your printing journey or looking to refine your techniques, understanding the distinctions between these materials can help you make better choices for your projects.

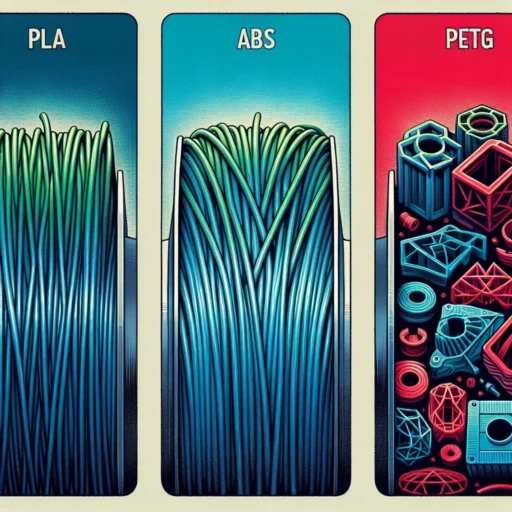

PLA (Polylactic Acid)

PLA is the go-to filament for beginners. Made from renewable resources like corn starch and sugarcane, it’s biodegradable and considered one of the more environmentally friendly options available. One of the standout characteristics of PLA is its ease of use. It adheres well to the build plate, typically doesn’t require a heated bed, and produces minimal warping. These factors make it ideal for novice users.

In terms of aesthetic appeal, PLA can achieve excellent detail and finishes, making it suitable for printing objects like prototypes, decorative pieces, and even some functional parts, particularly ones that won’t be subjected to high stress. However, while it performs well under typical conditions, PLA has a lower heat resistance compared to other materials. Exposure to temperatures above 60°C can cause it to deform, which limits its applicability for certain industrial applications.

Moreover, PLA prints at lower speeds, generally around 50-70 mm/s, which helps maintain print quality. And let’s not forget the vibrant colors! With a wide array of hues and even specialty filaments that can mimic wood, metal, and other materials, PLA is perfect for artistic projects.

ABS (Acrylonitrile Butadiene Styrene)

Next up is ABS, a staple in the 3D printing community, especially for those looking for strength and durability. ABS is petroleum-based, which means it isn’t biodegradable, but its toughness makes it suitable for functional parts and products that need to withstand mechanical stress—think automotive components or electrical housings.

One of the unique properties of ABS is its ability to withstand heat, making it a better choice for items that may be exposed to higher temperatures. However, working with it comes with its own set of challenges. Unlike PLA, ABS tends to warp when cooled, necessitating a heated bed during printing to help mitigate this issue. It also produces fumes when melted, so it’s advisable to print in a well-ventilated area.

Additionally, ABS can be smoothed using acetone, which helps create a glossy finish and can significantly improve the visual aesthetic of the final print. When it comes to speed, ABS can be printed at a range of speeds, but many find a sweet spot around 40-70 mm/s to achieve a fine quality.

PETG (Polyethylene Terephthalate Glycol-Modified)

If you’re looking for a middle ground between PLA and ABS, PETG is your best friend. This filament brings together the best characteristics of both materials—strength and ease of use. PETG is durable, impact-resistant, and exhibits good thermal properties, making it suitable for functional and mechanical parts, yet it retains enough flexibility to prevent snapping.

One of PETG’s standout benefits is its excellent layer adhesion and reduced warping tendencies compared to ABS, which helps in producing larger models without the concerns of deformation. It still does require a heated bed, but the temperatures are generally forgiving, usually between 70-80°C. Plus, PETG is less prone to fumes compared to ABS, making it a bit safer for home use.

PETG also boasts impressive clarity, providing that sleek, glossy finish that many users love. The trade-off? While it can print at faster speeds—around 50-80 mm/s—getting the right balance of print settings, including cooling and extrusion, is crucial to avoid issues like stringing, which can take away from the finished product’s appearance.

Choosing the Right Filament

With these options, how do you decide which filament is right for your project? It all boils down to your specific needs. If you’re new to 3D printing and want to create small prints with attention to detail, PLA is a safe bet. For industrial and functional projects requiring greater durability, ABS might be your choice. And when you require a balance of strength and ease of printing, don’t overlook PETG.

Ultimately, trial and error is part of the 3D printing adventure. Each material can open new avenues for creativity and utility, and understanding their unique properties informs not just your projects but your entire printing journey. As you explore quick prints, intricate designs, or robust prototypes, remember that the right filament can make all the difference. Happy printing!