Understanding the Printing Process: From 3D Model to Reality

In today’s tech-driven world, the phrase "I can print that!" takes on a whole new meaning. Gone are the days when printing simply referred to laying down ink on paper. With the rise of 3D printing, the landscape of manufacturing, prototyping, and even personal projects has transformed. But what does it really take to get from a 3D model on a screen to a tangible object in your hand? Let’s dive into the fascinating realm of 3D printing.

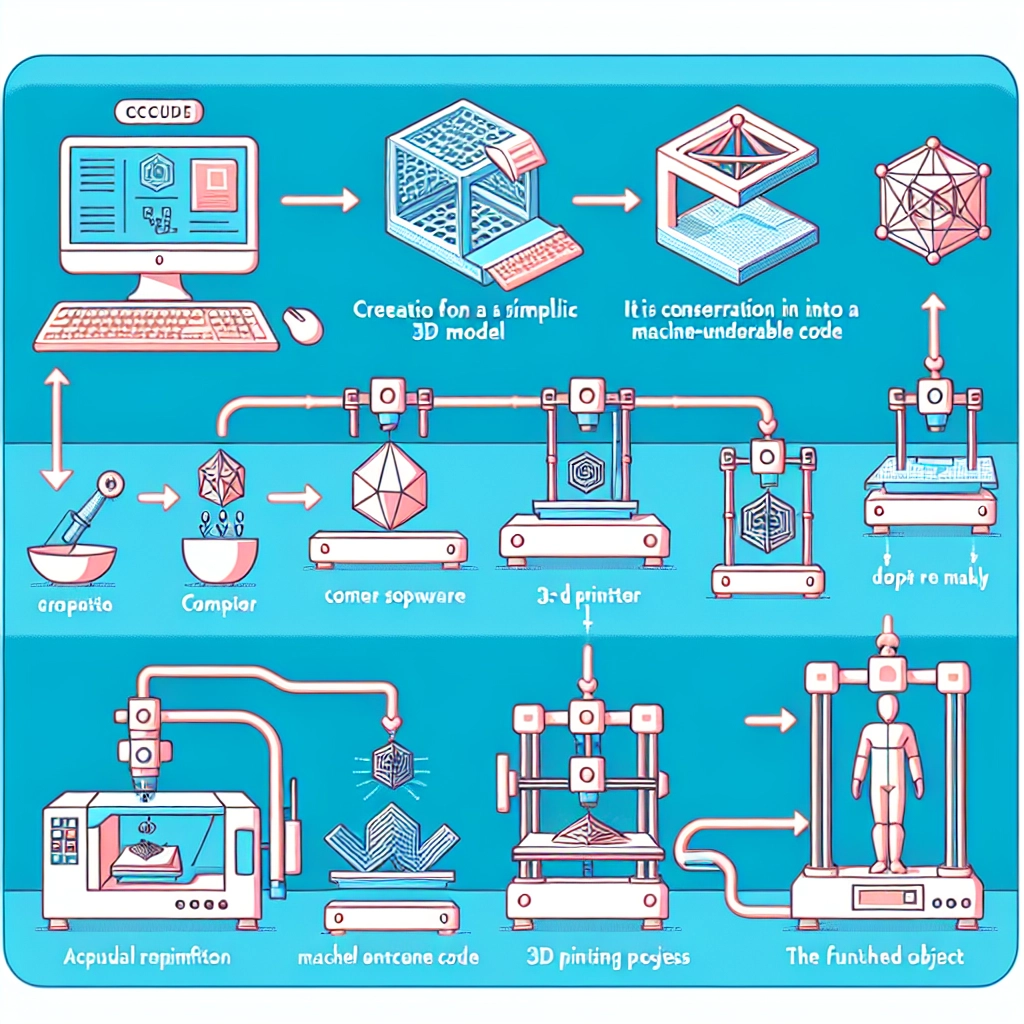

The Beginnings: Designing a 3D Model

Every great printed object starts with an idea, but before anything can be printed, it needs to be designed in three dimensions. The process typically begins with Computer-Aided Design (CAD) software, which allows designers to create detailed models that dictate every curve, angle, and texture of the final product. This design phase is a combination of creativity and technical know-how, as even the slightest miscalculation can lead to a failed print.

There are also numerous platforms and online repositories, such as Thingiverse or MyMiniFactory, where you can find pre-made designs. If you’re new to 3D modeling, these platforms can be a treasure trove of inspiration and ready-to-print files. And who knows, you might just want to customize these designs to add your personal touch!

Slicing the Model: Preparing for Print

Once the model is complete, it’s time to prepare it for printing through a process called “slicing.” This is where specialized software takes your 3D model and breaks it down into thin horizontal layers, creating a set of instructions known as G-code that the 3D printer will follow. Think of it as a recipe book for your printer, detailing every movement it needs to make to construct your object layer by layer.

During this slicing stage, you can also configure a variety of settings: layer height, print speed, fill density (how solid or hollow your object will be), and even support structures for any overhangs in your design. Each of these options can significantly influence not only the quality of the final print but also the time it takes to produce it.

The Printing Process: Layer by Layer

With the G-code ready, it’s time to hit print and let the magic happen. Depending on the type of 3D printer used, you might witness different printing technologies come into play. The most common method is Fused Deposition Modeling (FDM), where plastic filament is melted and extruded through a nozzle, gradually building each layer from the bottom up.

Alternatively, there’s Stereolithography (SLA), which uses a laser to cure liquid resin into solid layers. There’s also Selective Laser Sintering (SLS), which involves sintering powdered materials together, typically used in more industrial applications. Each of these processes has its own strengths and weaknesses, and the choice often depends on the intended application of the printed object.

As the printer continues to lay down layer after layer, you can witness the gradual transformation of digital creation into a physical reality. This is where real magic seems to occur; watching nothing turn into something is a truly mesmerizing experience!

Post-Processing: Refining Your Print

After the print completes, there’s often some post-processing work to be done. While the printer does an excellent job at creating the initial form, it might require a bit of finishing to look its best. This can include removing support structures, sanding down rough edges, or even painting to add color and details.

For some projects, particularly in the world of prototyping, post-processing can also mean functional tests to ensure the part meets its intended specifications. After all, the beauty of 3D printing lies not just in aesthetics but also functionality!

Bringing It All Together

3D printing represents a remarkable bridge between imagination and reality. It allows us to experiment, prototype, and create things we might not have thought possible just a few years ago. From group projects like custom jam jars for a local market to complex engineering applications in aerospace—a diverse set of gifts flows from 3D printing capabilities.

As we continue to explore this technology, who knows what incredible creations are yet to come? Whether you’re a hobbyist, a professional, or just curious, the world of 3D printing invites you to step into a future where your only limit is your imagination. With each layer laid down, you’re not just creating a physical object; you’re cultivating innovation and creativity one print at a time. So grab your design software or explore some ready-made models; the 3D world is waiting for you to bring your ideas to life!