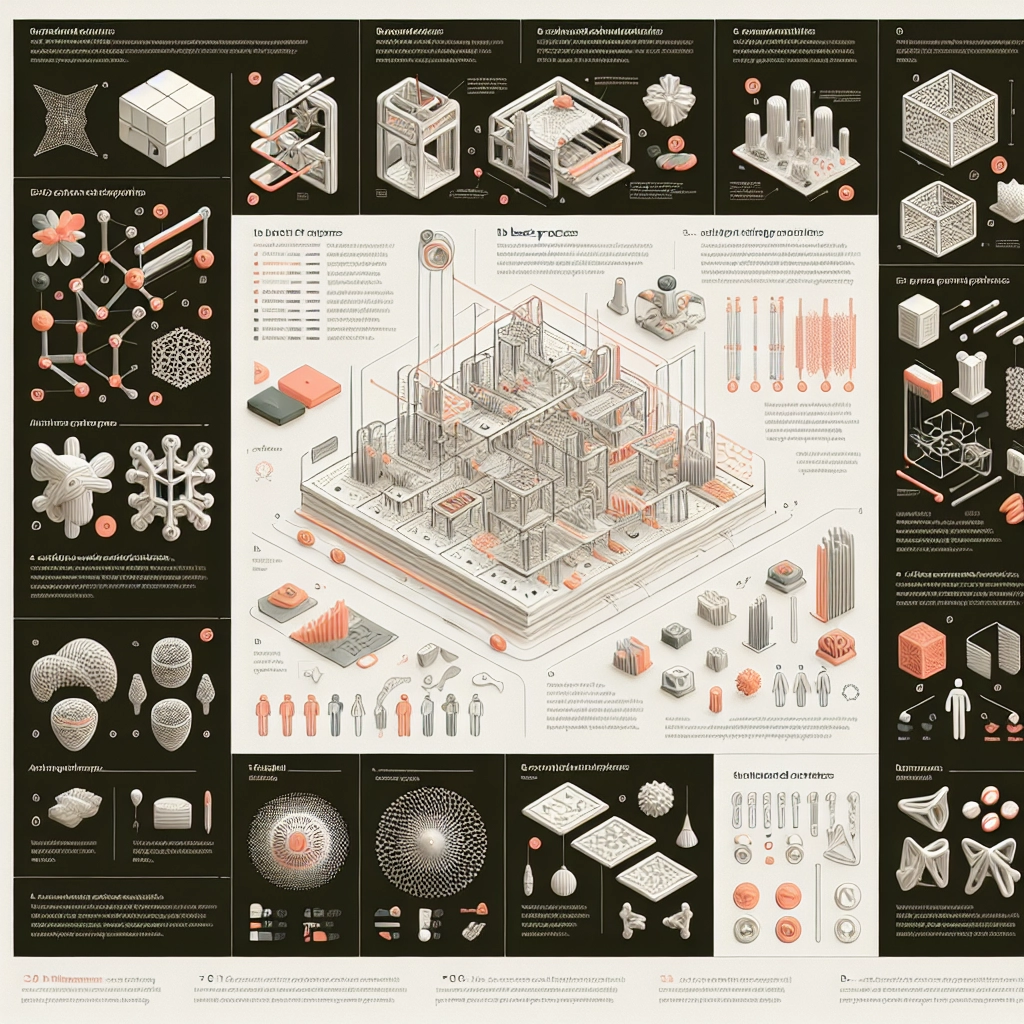

The Art of Designing for 3D Printing: Best Practices

3D printing has revolutionized the manufacturing landscape, allowing designers and creators to turn their wildest ideas into tangible realities. However, jumping straight into designing can be overwhelming—there’s a learning curve that goes beyond just hitting the print button. Whether you’re a hobbyist, an engineer, or someone looking to create a unique gift, understanding the art of designing for 3D printing is essential to producing successful prints. Let’s explore some best practices that will make your 3D design experience smooth and enjoyable.

Understand Your 3D Printer

Before diving into design, it’s critical to have a grasp of the specific 3D printer you’ll be using. Different printers have varying capabilities, materials, and constraints. For example, a consumer-grade FDM (Fused Deposition Modeling) printer typically uses filament and has specific limitations when it comes to speed, layer height, and resolution. On the other hand, SLA (Stereolithography) printers use resin and can produce much finer detail but come with their own set of challenges, such as post-processing requirements.

Start by consulting your printer’s specifications. Familiarize yourself with its build volume, layer resolution, and tolerances. Knowing your machine’s limits will help you design appropriately from the get-go.

Design for Printability

Now, let’s talk design. It’s easy to get carried away with creativity, but it’s equally essential to think about printability. Here are a few tips:

-

Overhangs: Most FDM printers struggle with overhangs. If your design has parts that extend without support, consider adding supports in your design or making adjustments with angles less than 45 degrees.

-

Bridging: Similar to overhangs, bridges—areas where the printer must span gaps without any support—need careful consideration. You can minimize the need for support by keeping bridges short and the distance they need to cover within 20mm if possible.

-

Wall Thickness: Ensure your walls are thick enough for stability, usually around 1.2mm, depending on the material and printer settings. Thin walls could lead to failures during printing.

-

Avoiding Small Features: If you’re designing something intricate, keep in mind that very small details may not print well and could get lost in the process. A size of at least 0.5mm for features is generally recommended for FDM printing.

Choose the Right Material

The material you choose for your design can impact its aesthetic and functionality. Common materials include PLA, ABS, PETG, and TPU, each with its own set of properties. PLA is often favored by beginners because of its ease of use and biodegradability, while ABS offers greater durability for items that need to withstand heat.

Think strategically about what you plan to do with your printed object. For example, if you’re creating a functional part, you might opt for a more resilient material like ABS. Conversely, if you’re making an artistic piece, there are myriad colorful PLA filaments that can help your work pop!

Leverage Software Tools

There are endless design tools available, each featuring various functionalities to help streamline your workflow. Popular options like Tinkercad, Fusion 360, and Blender can cater to different levels of skill and project complexity. Tinkercad is fantastic for beginners, while Fusion 360 offers an advanced suite of capabilities for more experienced designers.

Don’t forget to take advantage of software that allows you to visualize your design in a 3D space and run simulations to predict how your model will behave during the print process. These tools can catch potential flaws before you invest time and materials!

Test, Adjust, Repeat

3D printing is as much about experimentation as it is about skill. Don’t be discouraged if your first print doesn’t turn out perfectly. Each failure provides valuable learning opportunities that lead to better designs. Consider doing smaller test prints to hone specific aspects of your design, such as fitting or the function of movable parts.

Embrace the iterative process; tweaking your design based on test results is a fundamental part of perfecting it. Over time, you will refine your skills, and getting from concept to creation will feel more seamless.

Final Thoughts

Designing for 3D printing is an exhilarating journey filled with creativity and innovation. By keeping in mind your printer’s specifications, focusing on printability, selecting suitable materials, utilizing the right software, and iterating through your designs, you can embrace the full potential of 3D printing. It’s about unlocking your imagination and bringing ideas to life, one layer at a time. So grab your software, fire up your printer, and let your creativity soar!