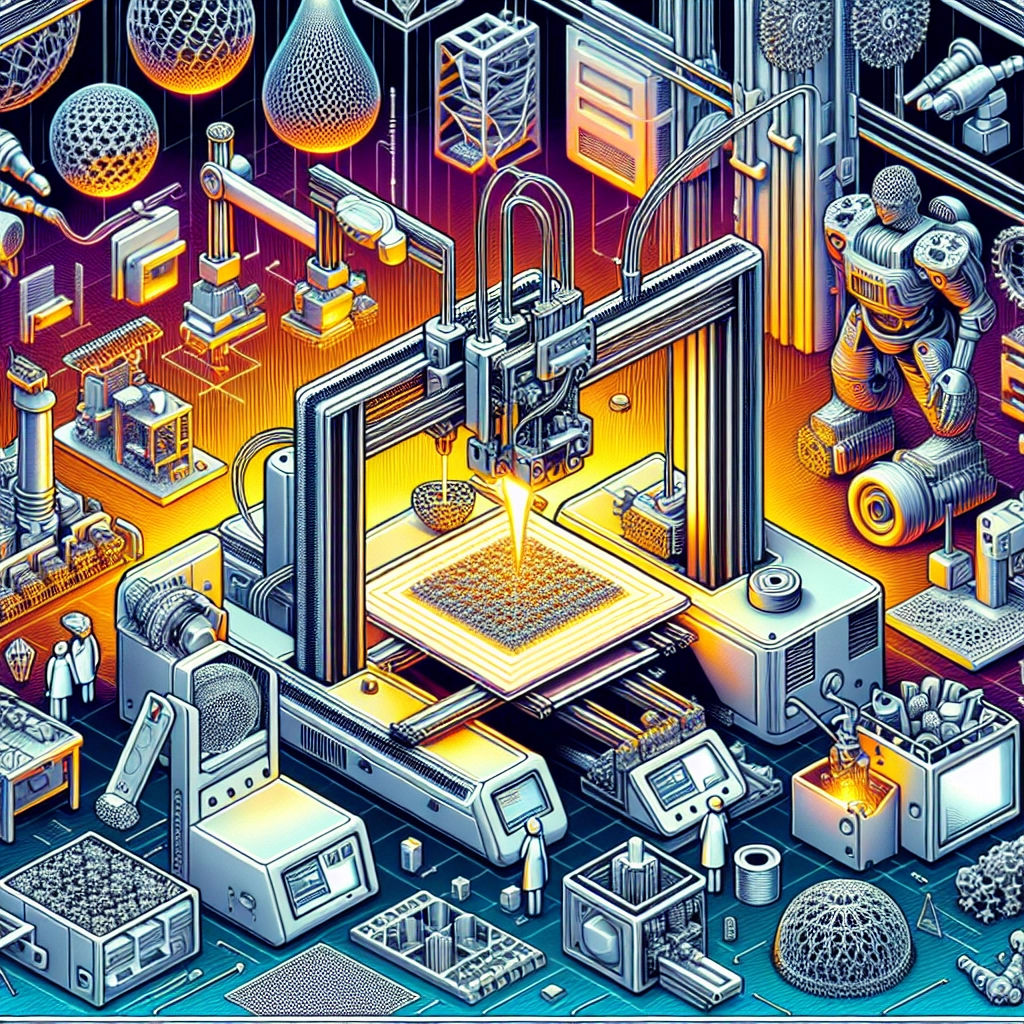

Exploring Advanced 3D Printing Techniques

3D printing has come a long way since the first commercial machines hit the market. It started as a tool for rapid prototyping and is now an integral part of industries as diverse as aerospace, healthcare, automotive, and fashion. But what some might not realize is that the exciting world of 3D printing continues to evolve, thanks to advanced techniques that are pushing the boundaries of what’s possible. Let’s dive into some of these cutting-edge methods and explore how they’re reshaping the landscape of manufacturing and innovation.

Boundless Materials

One of the most thrilling advancements in 3D printing is the expansion of printable materials.

Gone are the days when you were limited to just plastic filament or resin. Nowadays, you can print in metals, ceramics, glass, and even living cells!

Metal 3D Printing has gained traction, especially in the aerospace and automotive sectors, where components made from titanium, aluminum, or stainless steel can lead to significant weight reductions while maintaining strength. This is crucial in industries where every ounce matters. The process typically utilizes Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM), where a laser fuses powdered metal into solid forms.

Bioprinting is another frontier that’s capturing attention. Utilizing living cells, researchers are working toward the ability to create tissues and potentially even organs for transplant. Can you imagine a world where organs are 3D printed to match a patient’s unique biological makeup? We may be closer to that reality than we think.

Speed Meets Precision

While traditional 3D printing techniques tended to take hours (if not days) to produce high-quality prints, advanced methods are drastically improving the speed and accuracy of the process.

Continuous Liquid Interface Production (CLIP) is one such technology that promises to output parts in a fraction of the time traditional stereolithography would require. By curing a resin in a continuous motion—allowing for simultaneous printing of multiple layers—CLIP can produce high-resolution prints within minutes rather than hours. This is exceptionally beneficial for industries that require rapid prototyping or small-batch production.

Additionally, Multi Jet Fusion (MJF) is another game-changer that delivers robust, high-quality nylon parts. MJF utilizes an inkjet array that selectively applies a fusing agent onto a nylon powder bed, which is then heated to create solid parts. The ability to manufacture multiple parts at once means lower costs and quicker turnarounds—a win-win for manufacturers.

Combining Technologies

What if printing wasn’t just about shaping a single object, but about integrating multiple functionalities into one piece? This is where hybrid manufacturing shines. By combining additive and subtractive manufacturing processes, engineers can create highly complex parts that leverage the strengths of both methods. For instance, a part can be 3D printed and then subjected to CNC milling for intricate detail, enhancing the overall quality and precision.

Another fascinating aspect of hybrid technology is the incorporation of electronics into 3D printed objects. Imagine a 3D printed lamp that can adjust its brightness based on the time of day or even a sports shoe with embedded sensors that provide real-time data on your performance. This not only increases functionality but also reduces the need for additional assembly, streamlining the production process.

Sustainability in Focus

As the world seeks more sustainable options, this goes for 3D printing, too. Techniques such as recycled materials and bio-based filaments are gaining traction. Some companies are now using waste products to create new printing materials, drastically reducing environmental impact. Innovations in print technology are allowing brands to upcycle plastic waste into usable filament, promoting a circular economy within the industry.

Furthermore, the precision of 3D printing means that materials are used more efficiently. Traditional manufacturing can create a lot of waste through cutting and machining, while 3D printing builds objects layer by layer, minimizing leftover materials.

The Road Ahead

As we explore these advanced techniques, it’s clear that 3D printing is evolving beyond just a manufacturing method; it’s becoming a revolutionary technology that could influence our way of life. We’re witnessing advancements that make industries more efficient, products more tailored to individual needs, and approaches more sustainable.

It’s an exciting time to be involved in the world of 3D printing, whether as a consumer, a hobbyist, or a professional. As these technologies continue to develop, we can only imagine the challenges and solutions that will emerge. The possibilities seem endless, and who knows—maybe the next breakthrough in 3D printing is just around the corner, waiting to reshape our future.