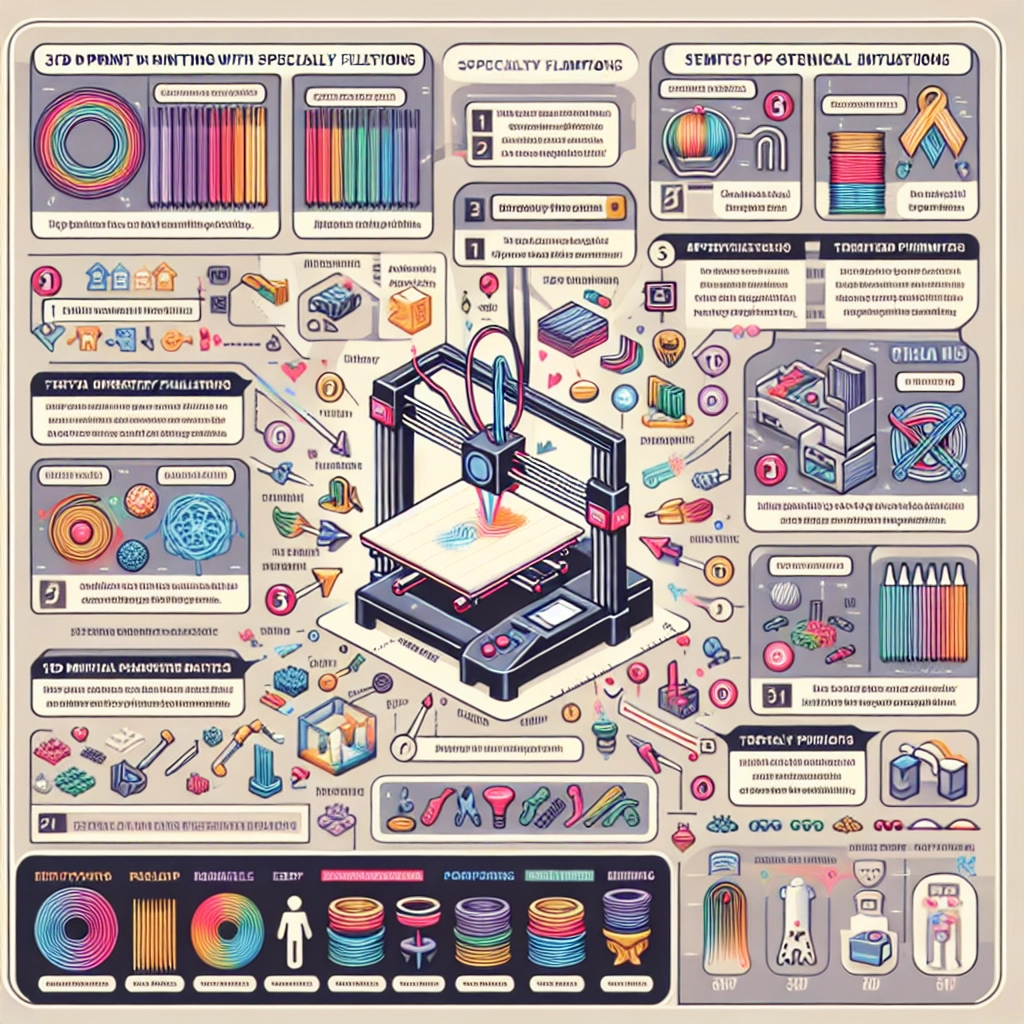

Tips for 3D Printing with Specialty Filaments

3D printing opens up an exciting world of possibilities, especially when you start experimenting with specialty filaments. These materials can elevate your prints in terms of durability, flexibility, aesthetics, and even unique properties like heat or chemical resistance. If you’re eager to take your 3D printing game to the next level, here are some helpful tips focused on making the most of those special filaments.

Understand Your Filament

Before you dive into printing, it’s crucial to know what you’re working with. Specialty filaments come in a variety of types, including but not limited to:

- ABS (Acrylonitrile Butadiene Styrene): Known for its toughness and impact resistance. It’s also great for functional parts.

- PETG (Polyethylene Terephthalate Glycol-modified): A fantastic mix of strength and flexibility, often used for food-safe applications.

- TPU (Thermoplastic Polyurethane): A flexible filament perfect for creating rubber-like objects, great for phone cases or any protective gear.

- Nylon: Renowned for its strength, it can be tricky to print but is incredibly durable.

- Composite Filaments: These mix base materials with other substances like wood or metal, providing a unique finish and surface texture.

Spend some time researching the specific filament you intend to use. Familiarize yourself with its temperature requirements, bed adhesion characteristics, and suggested print speeds. Manufacturers often provide guidelines, so keep that information handy!

Adjust Your Settings

Every filament has its sweet spot when it comes to printing settings.

-

Temperature: Specialty filaments usually have specific temperature requirements. For example, ABS requires higher temperatures than PLA. Make sure you calibrate the nozzle temperature and, if necessary, the heated bed to achieve optimal adhesion.

-

Print Speed: Slower speeds can often yield better results with more challenging materials like Nylon or TPU. If you’re experiencing issues, try reducing the speed gradually until you find a balance.

-

Layer Height: A smaller layer height can lead to finer details, which is particularly important if you’re using materials with added textures like wood or metal composites.

Consider Bed Adhesion

Materials like Nylon and TPU might not adhere as well as more common options like PLA. To help with bed adhesion:

-

Use a Heated Bed: Keeping the print bed hot can significantly help with sticking issues. For Nylon, a bed temperature of around 70-80 degrees Celsius usually works well.

-

Apply Adhesives: Tape (like painter’s tape), glue sticks, or specialized adhesives can provide extra grip for tricky filaments. Experiment a bit to see what works best for your material.

-

Rafts and Brims: Using a raft or brim can increase the surface area in contact with the bed, supporting better adhesion, especially for tall or slender prints.

Keep Things Clean

Specialty filaments often require more care in terms of cleanliness. For example:

-

Avoid Moisture: Many advanced materials are hygroscopic, meaning they absorb moisture from the air. Keep them sealed in airtight containers with desiccants when not in use. If your Nylon filament feels dusty or brittle, it might need to be dried out.

-

Maintenance: Regularly check your printer’s nozzle for clogs, especially when switching between different types of filaments. A clogged nozzle can cause inconsistent flow and lead to print failures.

Experiment and Iterate

A big part of the joy of 3D printing is experimentation. Try different settings, temps, and situations. No two filaments are the same, and you may find that your unique setup requires a bit of tweaking to maximize results.

-

Test Prints: Always initiate your journey with specialty filaments with a small test print to ensure settings yield good results before going all out on large projects.

-

Document Your Findings: Keep notes of what works and what doesn’t with each filament. This not only helps improve your skills but also builds a valuable reference for future projects.

3D printing with specialty filaments can be a rewarding creative process that leads to stunning, functional pieces. By understanding your materials, adjusting settings correctly, ensuring proper bed adhesion, maintaining cleanliness, and taking the time to experiment, you’ll unlock the full potential of these unique materials. So grab your printer, unleash your imagination, and get ready to create some extraordinary prints!