What You Need to Know About 3D Printer Maintenance

If you’ve jumped into the world of 3D printing, you’re likely familiar with the excitement of creating your own designs, prototypes, and even miniatures. However, just like any other piece of technology, 3D printers require maintenance to ensure they function at their best. Regular upkeep can drastically extend the life of your printer and improve the quality of your prints. So, let’s dive into some essential tips and tricks for keeping your 3D printer in tip-top shape!

Cleaning the Print Bed

One of the simplest but most important maintenance tasks you can perform is cleaning the print bed. Dirt, dust, and leftover filament can lead to uneven prints or adhesion issues. Depending on the material of your print bed, you’ll want to use different cleaning agents. For a glass bed, isopropyl alcohol (IPA) on a soft cloth works wonders. For a BuildTak or PEI surface, warm soapy water might be the way to go—just ensure it’s completely dry before printing again. Regularly cleaning the print bed ensures your prints stick better, leading to fewer failed projects.

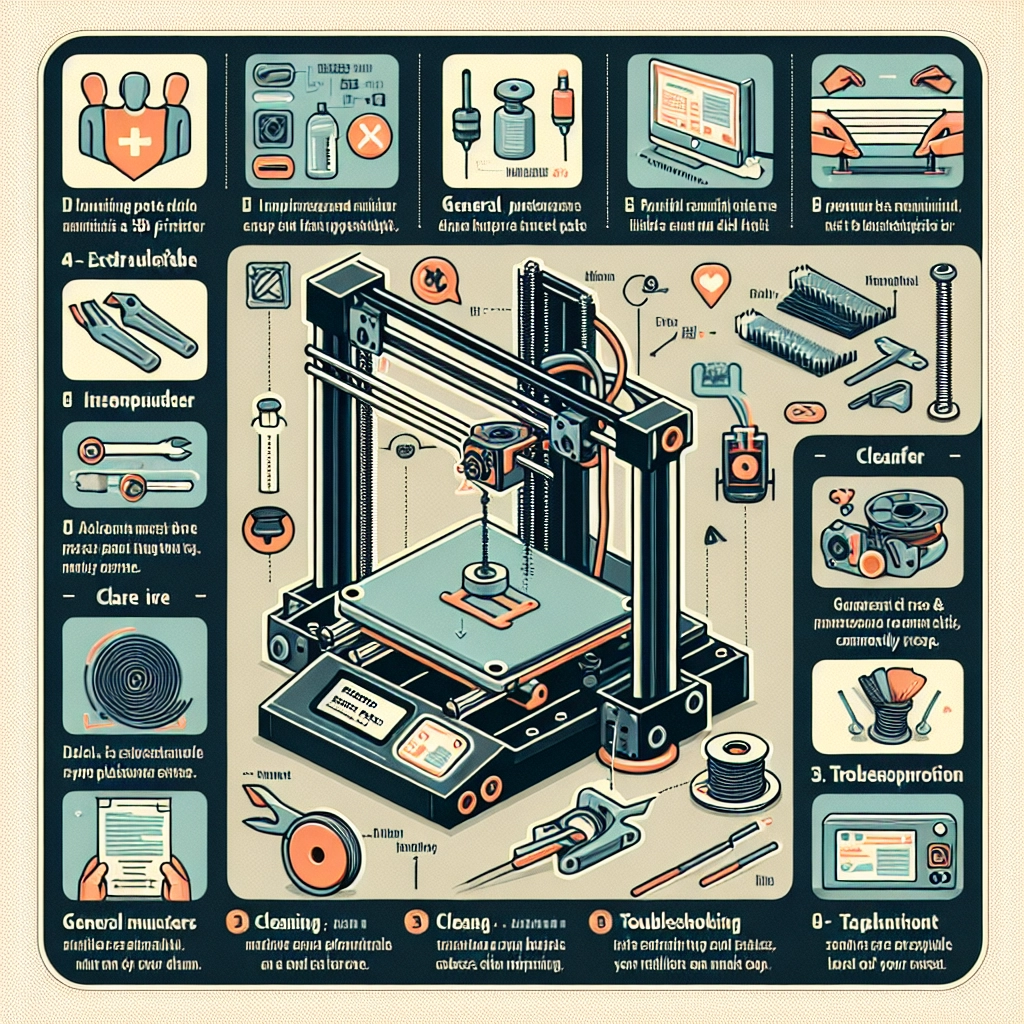

Checking the Nozzle

Your printer’s nozzle is where the magic happens, and keeping it clear is crucial for smooth operation. It’s not uncommon for residue or filament clogs to develop, especially if you’re changing materials frequently or using specialty filaments. Regularly inspecting your nozzle for blockages can save you a headache later. If you suspect a clog, a simple cold pull method (where you heat the nozzle to the melting point of the filament and pull it out) can effectively clear any debris. For a deeper clean, you may need to remove the nozzle and soak it in acetone.

Lubrication and Movement

Your 3D printer’s moving parts, like the rails and lead screws, should be lubricated regularly to keep everything running smoothly. A little bit of machine oil goes a long way in preventing wear and tear. This is especially true for printers that see heavy use. Make it a point to add lubrication monthly, or every few prints if you’re frequently churning out projects. Just be careful not to over-apply it; a thin layer is usually enough.

Calibrate, Calibrate, Calibrate

Calibration is one of those tasks that’s easy to overlook, but it’s integral to maintaining print quality. From leveling the print bed to ensuring the extruder is correctly calibrated, each step is crucial for achieving great results. A poorly calibrated printer can lead to all sorts of print issues like misalignment, stringing, and layer separation. Periodically check your bed leveling, even if you think it’s fine. As a rule of thumb, many hobbyists recommend checking it every few weeks or after any major movement or transport of the printer.

Firmware and Software Updates

Just like with any tech, keeping your firmware and slicing software up-to-date can have a significant impact. Manufacturers often release updates that improve performance, fix bugs, and sometimes even add new features. Take a moment to check for any available updates periodically. And remember, before updating firmware, back up your current settings, just in case!

Extrusion and Temperature Checks

Materials behave differently based on their temperature, and ensuring your printer is correctly set for the filament you’re using can save you lots of frustration. If you often switch between materials, take the time to double-check that the temperature settings match what’s recommended. Additionally, watch for signs of under-extrusion or over-extrusion, which can indicate clogs or misalignments. If your prints look messy or aren’t adhering properly, adjusting your temperature settings could resolve those pesky issues.

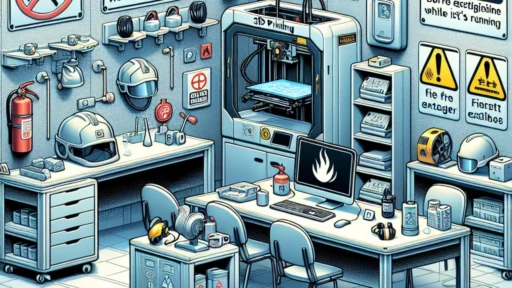

Keeping the Workspace Clean

Lastly, remember that a clean workspace is just as important as maintaining the printer itself. Dust and debris can migrate into your printer, affecting performance and print quality. Regularly clean around your setup, and try to keep the area dust-free. Also, store your filament in airtight containers or vacuum-sealed bags to keep moisture at bay.

Final Thoughts

3D printer maintenance may seem daunting at first, but once you get into the routine of it, you’ll find it doesn’t take much time at all—yet the benefits are huge! Taking these small steps can lead to smoother operation, better print quality, and a longer lifespan for your prized machine. So, roll up your sleeves and show your 3D printer a little love; you’ll be amazed at how much of a difference it makes in your printing experience! Happy printing!