3D Printing Failures: Learning from Mistakes to Improve Your Skills

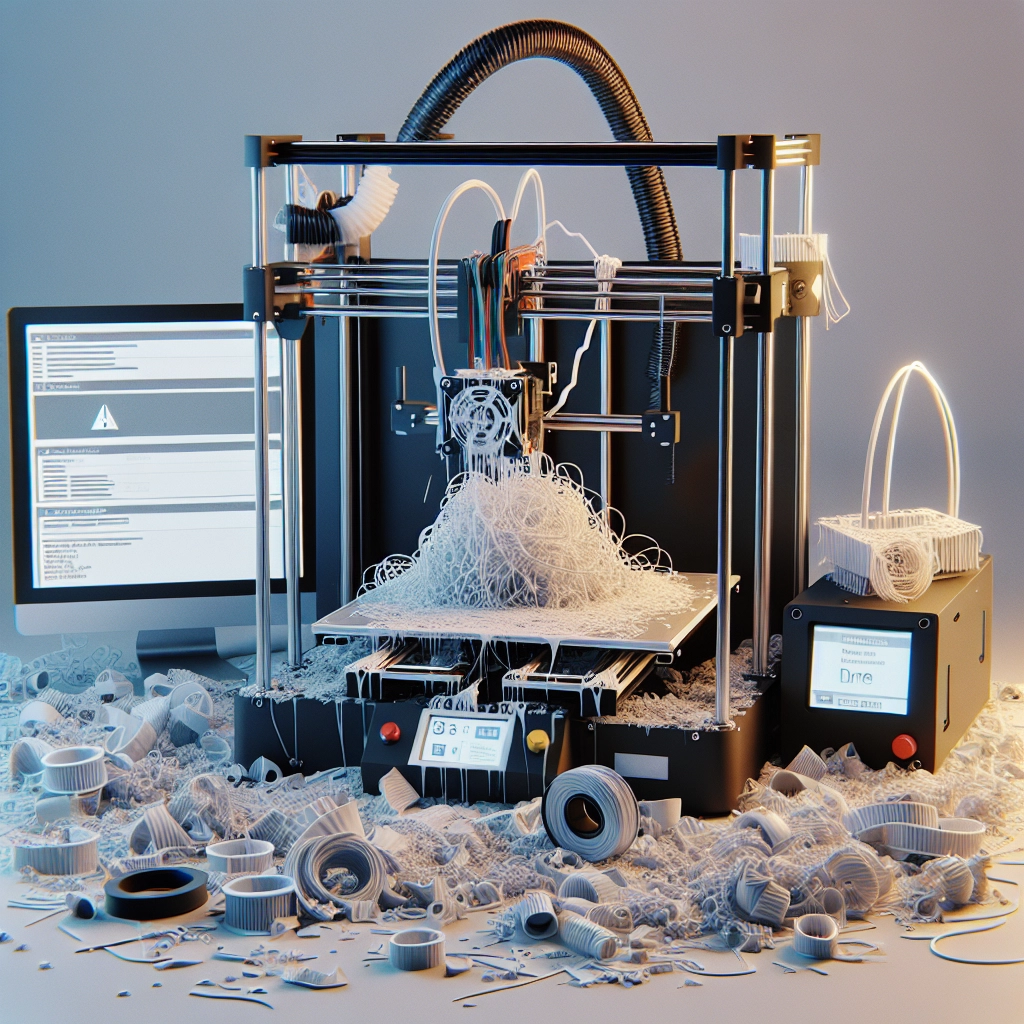

If you’ve dipped your toes into the world of 3D printing, you know it’s a thrilling realm filled with endless possibilities. Turning digital designs into tangible objects can feel like a little miracle each time the printer whirs to life. Yet, for many of us, the process isn’t always smooth sailing. In fact, encountering failures is practically a rite of passage in 3D printing. Instead of letting these hiccups discourage you, why not lean into them? Learning from mistakes can supercharge your skills and transform setbacks into a pathway for growth.

Common 3D Printing Failures

Let’s start by shining a light on some common issues that can lead to frustrating outcomes. Whether you’re a rookie or a seasoned enthusiast, these failures might sound all too familiar:

-

Warpage: Nothing disrupts a focused printing session quite like that moment you notice your print has warped. This often happens when the base cools unevenly, causing the material to lift from the build platform. Larger prints are particularly susceptible.

-

Stringing: If you’ve seen thin strands of plastic reminiscent of spider webs lingering between parts of your print, you’ve just encountered stringing. This usually happens when the extruder nozzle moves without retracting the filament properly.

-

Layer Separation: Imagine a beautiful print that starts to look more like a jigsaw puzzle than a cohesive object. Layer separation occurs when the layers of filament fail to bond properly, often due to insufficient temperature or cooling issues.

-

Clogged Nozzle: A classic nemesis, the clogged nozzle can halt your printing session as quickly as it began. If your printer starts to spit out weak, under-extruded plastic — or worse, nothing at all — it’s likely time to address that pesky blockage.

-

Poor Bed Adhesion: We all want our prints to stick around! When prints don’t adhere properly to the print bed, it can feel like they have a mind of their own. This is particularly annoying and often leads to prints that are either incomplete or entirely failed.

Turning Failures into Learning Opportunities

So, what can we do when these inevitable failures pop up? The first step is to realize that every misstep is an opportunity to learn and improve. Here’s how you can turn those pesky problems into powerful lessons:

1. Analyze and Diagnose

Each failure is a puzzle waiting to be solved. Start by examining your print carefully to identify issues. Was the print temperature correct? Does the filament look like it’s melting properly? Taking notes will help you track the patterns underlying your failures.

2. Research Solutions

Once you’ve pinpointed your problem, dive deep into the wealth of online resources available. Forums, YouTube tutorials, and blogs dedicated to 3D printing are treasure troves of information. Chances are, someone else has faced the same problem and found a solution you hadn’t considered!

3. Experiment and Test

3D printing is all about experimentation. Don’t shy away from trying out different printer settings, adjusting temperature, or even switching to a different type of filament. Printing with smaller, test objects can save you material and time while you’re working through the kinks.

4. Join a Community

There’s an entire community of 3D printing enthusiasts who are eager to share their experiences and insights. Joining online communities, local maker spaces, or clubs can provide not only support but also a network of helpful individuals who can offer their wisdom.

5. Keep a ‘Failure Journal’

In the same way that athletes learn from their mistakes, keeping a journal to document your printing journey can be incredibly beneficial. Documenting the failures, what you learned, and what adjustments you made afterward will create a personal knowledge base to guide you through future projects.

3D printing is as much about creativity as it is about precision. Although the path may be fraught with mishaps, these failures can lead to amazing breakthroughs and discoveries in your printing journey. Each imperfect print brings you one step closer to becoming a pro, and as you refine your skills, you’ll be able to tackle increasingly complex designs with confidence.

In the end, embracing your failures is a cornerstone of mastery. So fire up that printer, give it another shot, and don’t forget to learn from every misstep along the way. Remember, the most successful 3D printing artists didn’t start as experts; they thrived through trial and error—and so will you!