The Future of 3D Printing: Innovations to Watch

Ah, the world of 3D printing—a realm where dreams take shape (pun intended) and imagination meets manufacturing tech! This incredible innovation isn’t just a novelty anymore; it’s reshaping industries from healthcare to construction. Every day, new advancements emerge that promise to push the boundaries of what’s possible. So, what can we expect in the coming years? Let’s dive into some exciting innovations that are set to revolutionize the 3D printing landscape.

Bioprinting: A Leap Towards Custom Healthcare

Imagine a future where the doctor doesn’t just prescribe a treatment but creates a personalized implant or tissue just for you. Bioprinting, a process that uses living cells to print tissues and organs, is quickly progressing toward that vision. Researchers are working tirelessly to perfect this technique, and it’s already making headway in areas like skin grafts for burn patients and dental applications.

In the years to come, we could witness the first successful transplant of a 3D-printed organ. This could dramatically reduce the waiting list for transplants and revolutionize how we approach organ donation. If that’s not exciting enough, think about the implications for drug testing. Instead of relying on traditional methods, pharmaceutical companies might use bioprinted tissues to conduct trials, leading to quicker and more effective drug development.

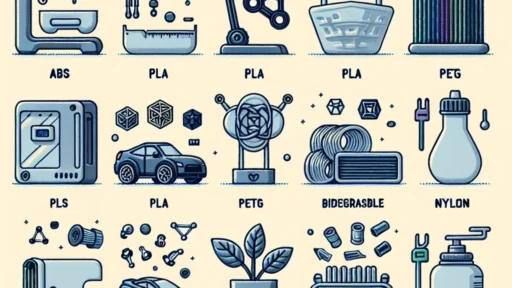

Sustainable Materials: Eco-Friendly Innovations

As concerns around climate change and waste grow, the push for sustainable 3D printing materials is more significant than ever. Innovations in biodegradable and recyclable materials are paving the way for greener manufacturing processes. Companies are beginning to experiment with materials made from plant-based sources, such as algae or cornstarch, turning 3D printing into a more environmentally friendly endeavor.

Moreover, organizations are focusing on recycling wasted 3D printing material. Imagine printing your new coffee mug not from raw plastic but from the remnants of old plastics that would otherwise end up in a landfill. This circular economy approach could help to not only mitigate waste but also change the way we think about our consumption and manufacturing practices.

Construction and Architecture: Building the Future

3D printing isn’t just limited to small objects; it’s making its mark in the construction industry! Imagine entire houses printed in a matter of days instead of months. Companies are developing large-scale 3D printers that can create walls and structures layer by layer. This technology isn’t just faster; it also has the potential to lower costs and reduce material waste.

We’re already seeing projects where entire neighborhoods are being constructed using 3D printing techniques, providing affordable housing solutions in areas that desperately need them. Plus, with the ability to incorporate complex designs with less hassle, architects are being given a new canvas to create astonishing, sustainable buildings. Who wouldn’t want to live in a beautifully designed space that was created quickly and efficiently?

Aerospace and Automotive: Lightweight Solutions

The aerospace and automotive industries are always on the lookout for ways to improve efficiency and performance, and 3D printing is fueling this ambition. Lightweight parts are crucial for fuel efficiency, and 3D printing allows manufacturers to create intricate designs that traditional methods simply can’t achieve. This leads to components that are not only lighter but also stronger, which is a game-changer for everything from aircraft to sports cars.

Even major companies like Boeing and General Motors are investing heavily in metal 3D printing technologies to produce high-performance parts. These advances could lead to significant cost reductions and more efficient production timelines, ultimately benefiting consumers too.

The Rise of On-Demand Printing

One of the most exciting trends in 3D printing is the shift toward on-demand production. Gone are the days of overstocking warehouses and supply chain headaches. With 3D printing, manufacturers can produce items as needed, reducing waste and improving inventory management.

Imagine ordering a part for your car or home appliance, and instead of waiting weeks, it arrives in a day—because it was printed just for you. This level of customization isn’t far off, as more companies embrace the idea of localized, on-demand production. It’ll mean faster deliveries and less waste, which sounds like a win-win, right?

In a world that’s constantly evolving, 3D printing stands out as a beacon of innovation. It’s not just about the technology itself; it’s about the possibilities it unlocks in every sector. As we look ahead, the potential for 3D printing to create a more personalized, sustainable, and efficient world seems boundless. With each development, we inch closer to a future where our imaginations can manifest into reality, layer by layer. So, whether you’re an entrepreneur, a hobbyist, or just curious about tech, keep your eyes on this incredible field—it’s going to be a thrilling ride!