The Evolution of 3D Filaments: What You Need to Know

In the age of innovation, 3D printing has emerged as one of the most thrilling technologies of our time. It’s like wielding magic; with a few clicks, you can bring ideas to life. However, while you might be acquainted with the impressive mechanical arms of a 3D printer, it’s the humble filament that often takes the spotlight (or the plate, in this case). The evolution of 3D filaments has been nothing short of fascinating, paving the way for new materials and techniques that change the way we create. So let’s dive into this colorful world and explore everything you need to know about 3D filaments!

The Basics of 3D Filaments

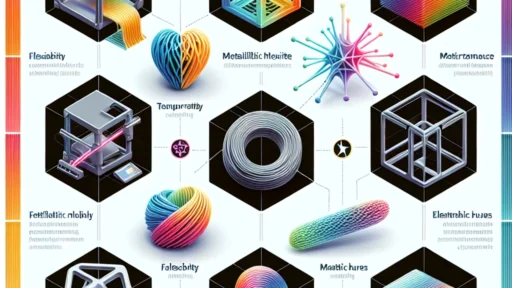

Before we dive into the nitty-gritty, let’s cover the essentials. A 3D filament is a material used in FDM (Fused Deposition Modeling) printers, the most common type of 3D printing technology. Think of filament as the ‘ink’ for your printer. These filaments come in various materials—each with unique properties that make them suitable for different projects. The most popular ones include PLA, ABS, PETG, and TPU.

- PLA (Polylactic Acid) is derived from renewable resources, like corn starch, making it biodegradable, easy to print, and excellent for beginners.

- ABS (Acrylonitrile Butadiene Styrene) is durable and heat-resistant, perfect for functional parts but a bit tricky to print due to its tendency to warp.

- PETG (Polyethylene Terephthalate Glycol) offers a sweet spot between PLA and ABS, boasting good strength, flexibility, and printability.

- TPU (Thermoplastic Polyurethane) is the go-to for flexible prints, allowing you to create rubbery pieces like phone cases or complex designs.

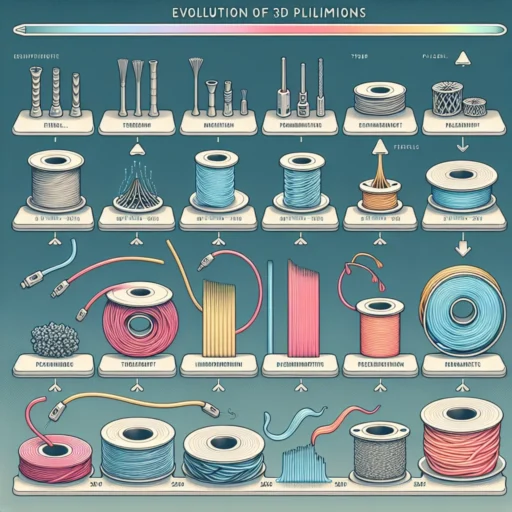

Early Days of 3D Printing Materials

When 3D printing first made waves in the early 1980s, the available materials were quite limited. The first commercially available materials were mostly specialty plastics, but there was a strong push for better versatility in the 1990s and early 2000s. The introduction of ABS and PLA in this era opened doors for not only hobbyists but also industries looking for rapid prototyping solutions.

PLA quickly became the darling of the 3D printing community. It’s non-toxic, emits low odors when printing, and can yield beautifully detailed models. As printers became more accessible and affordable, we saw a surge in creativity among makers who wanted to experiment with different types of filaments.

The 2010s: A Surge in Diversity

Fast forward to the 2010s, and the world of 3D filaments exploded! Companies began to experiment with composite filaments, incorporating materials like wood, metal, and carbon fiber into the mix. This innovation allowed 3D-printed objects to not only look intriguing but also offer functional advantages, such as increased strength or a unique aesthetic.

For instance, wood-filled filament contains tiny dust particles, lending a wooden appearance to prints, while metal composites can create objects with a metallic sheen—perfect for artists and designers. Carbon fiber filament introduced a whole new level of strength-to-weight ratio, capturing the attention of engineers and professionals in aerospace and automotive industries.

Today and Beyond: Sustainable Options

In the last few years, the trend has shifted towards sustainability. With a growing awareness of plastic waste, manufacturers are investing in eco-friendly filaments. Recycled plastics and biopolymers are emerging as viable options for conscientious consumers. Furthermore, various companies are producing filaments that are specifically designed to be recyclable, which is a game-changer for the environment.

Another exciting trend is the development of smart materials that can change properties after printing. Think about color-changing filaments or filaments that can conduct electricity—how cool is that?

What’s Next for 3D Filament Technology?

As the industry pushes forward, we can only imagine what the next decade will hold for 3D filaments. We’re on the brink of breakthroughs in material science, which could lead to filaments that are lighter, stronger, and even multi-functional. The prospect of printing intricate electronics or medical implants is an exciting frontier that’s being explored right now.

So, whether you’re a seasoned maker or just stepping into the world of 3D printing, the evolution of filaments presents endless opportunities. With each new filament type, we’re not just improving our ability to create; we’re also fostering a community of innovation and collaboration. The journey of 3D filaments is a reflection of how creativity knows no bounds, and as this technology continues to evolve, we’re in for thrilling times ahead. Embrace the change, experiment with new materials, and who knows—you might just create something extraordinary!