3D Print Failures: Learning from Mistakes

3D printing is an exciting frontier of technology that allows us to turn imagination into reality with a few clicks and a spool of filament. But all that glitters is not gold. For every perfect print, there are often many that fall flat—quite literally. Experienced makers know that a part of the 3D printing journey involves failure. So, let’s dive into the world of 3D print failures, explore common pitfalls, and learn how these hiccups can help us improve our printing game.

The Reality of 3D Printing

If you’re new to the 3D printing world, you might envision gallant robots crafting flawless objects. The reality, however, is a bit messier. Sure, there are breathtaking successes, but many prints come off the bed resembling something out of a horror movie. The good news? Each failed print is a lesson waiting to be uncovered.

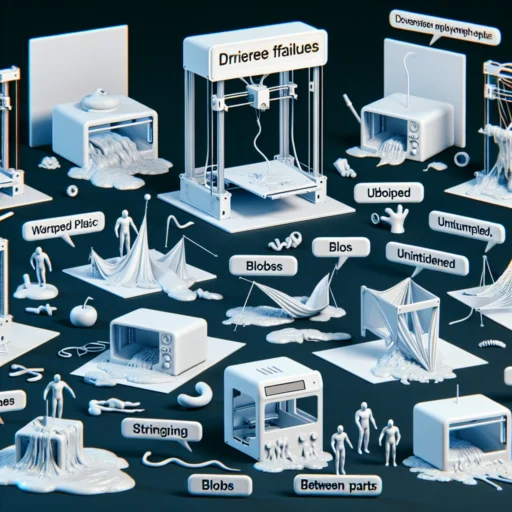

Common 3D Print Failures and Their Causes

1. Warping

One of the most dreaded issues is warping. You start off strong, but halfway through the print, it begins to lift from the print bed. This can happen for several reasons: a temperature difference between the print bed and the surrounding air, or the adhesive used isn’t strong enough to hold the material in place.

Tip: Preheat your bed and ensure it’s clean and properly adhered. Using materials like blue painter’s tape or specialized adhesives can help lock your print in place.

2. Stringing

Ah, the infamous cobweb effect! While you may want to replicate a spider’s web in your home decor, the chances are you didn’t intend for that to happen with your 3D print. Stringing occurs when the print head moves from one point to another, creating fine strands of plastic that resemble spaghetti.

Tip: To reduce stringing, try increasing the retraction settings in your slicer software. This means pulling the filament back into the nozzle while traveling, which helps to minimize excess flow.

3. Layer Separation

Imagine a beautiful sculpture that looks like it’s shedding layers like a snake in summer. Layer separation usually occurs when the individual layers of a print fail to bond together strongly enough. This can happen due to a variety of factors, including low printing temperature, improper layer height, or a lack of infill.

Tip: Adjust your nozzle temperature or experiment with layer height for better adhesion. Increasing the print speed slightly can also help in certain cases, as the filament has less time to cool before the next layer is added.

4. Overextrusion

If your print looks like it has gone through a bubble bath, you might be dealing with overextrusion. This happens when too much material is pushed through the nozzle, leading to a gooey, messy print. It could be due to incorrect steps/mm settings, too high a temperature, or improperly calibrated slicing settings.

Tip: Check your printer’s calibration and refer to your filament manufacturer’s specifications regarding temperature and flow rate. Adjusting your flow rate down a notch can work wonders.

5. Underextrusion

On the flip side, a print can also suffer from underextrusion, where not enough filament is being extruded, leading to gaps and holes that make your print look less than stellar.

Tip: Regular maintenance and calibration of your printer are essential. Make sure your nozzle isn’t clogged and that the filament feeds smoothly from the spool.

Embracing the Learning Curve

Mistakes are part of the journey, and frankly, they can be just as rewarding as the successes. Every failed print offers insights and valuable lessons. Instead of viewing failures as setbacks, consider them stepping stones to mastery.

It’s also worth connecting with the vibrant community of 3D printing enthusiasts online. Platforms like Reddit, Facebook groups, and specialized forums teem with individuals ready to share their own war stories and tips.

Moreover, documentation can be an invaluable tool. Keep a journal of your prints, noting what’s worked and what hasn’t. This not only allows you to track your progress but also helps in retracing your steps when trying to troubleshoot future issues.

As you embark on your 3D printing adventure, remember that every expert was once a beginner, tangled in the web of trial and error. Embrace your mistakes as you refine your skills because in the world of 3D printing, every failure brings you one step closer to creating something truly magnificent. So fire up that printer, learn from your setbacks, and make magic happen!