Understanding the Different 3D Printer Technologies

The world of 3D printing is a fascinating one that’s constantly evolving. From prototypes to final products, this technology has opened up a realm of possibilities for industries and hobbyists alike. If you’re curious about the different types of 3D printing technologies, let’s dive into the most popular methods and what makes each one unique.

Fused Deposition Modeling (FDM)

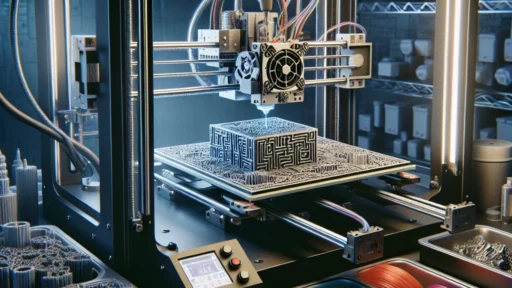

Fused Deposition Modeling, or FDM, is perhaps the most common type of 3D printing technology, especially for those just starting out. Imagine a hot glue gun that extrudes melted plastic instead of glue. That’s FDM in a nutshell!

In FDM, thermoplastic filaments—like PLA, ABS, or PETG—are heated and extruded layer by layer to create a 3D object. It’s widely used for creating prototypes, models, and even some functional parts due to its relatively low cost and ease of use. Plus, there’s a vast array of materials and colors available, giving you freedom and creativity in your projects. However, FDM prints can have visible layer lines, making post-processing necessary for highly detailed finishes.

Stereolithography (SLA)

Moving up the precision ladder, we have Stereolithography (SLA), which employs a different technique altogether. SLA uses a liquid resin that hardens when exposed to a specific wavelength of UV light. This process allows for incredibly high-resolution prints, making it an excellent choice for intricate designs and models.

While SLA printers can produce beautiful, smooth surfaces, they do require a bit more care—especially when it comes to handling the raw resin, which can be toxic. It’s worth noting that SLA prints often need a post-curing process to achieve optimal strength and accuracy, but the detail these machines can achieve is often worth the extra effort. Jewelers, dental professionals, and even some artists frequently turn to SLA for its precision.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) takes the cake when it comes to industrial applications. Instead of using filaments or resin, SLS works with powdered material—usually nylon or polyamide. A laser selectively fuses these powder particles together, layer by layer, until the entire model is complete.

One of the remarkable aspects of SLS is that there’s less need for support structures, unlike FDM or SLA. The unused powder acts as a support, allowing for more complex geometries. However, it’s essential to mention that SLS printers can be quite pricey and generally cater to businesses or serious hobbyists who require durability and strength in their models.

Digital Light Processing (DLP)

Similar to SLA, Digital Light Processing (DLP) uses a light source to cure resin. However, instead of targeting a single point, DLP uses a digital light projector to flash an entire layer of the model at once. This can make DLP prints faster compared to SLA, especially for producing larger objects.

The downside? Like SLA, DLP requires careful handling of the resin but offers comparable quality in terms of detail and finish. This method is gaining traction in various fields, including film, gaming, and jewelry design due to its efficiency and precision.

Bound Metal Deposition (BMD)

Bound Metal Deposition (BMD) is a relatively new player in the 3D printing arena, focusing on metal parts. It works in a similar way to FDM, using a bound metal filament that’s extruded and then heated in a sintering furnace to fuse the metal particles together.

BMD opens doors for manufacturers looking for complex metal parts without the high costs typically associated with traditional metal machining. However, as the technology is still maturing, potential users should consider safety and material availability before diving in.

Conclusion

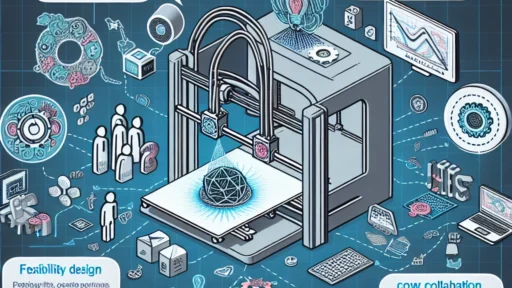

Navigating the different 3D printing technologies can be a bit overwhelming, but understanding the strengths and weaknesses of each method helps you choose the right one for your needs. Whether you’re a hobbyist aiming to create unique models, a professional seeking precision in prototyping, or even looking to dabble in metal printing, there’s a 3D printing technology that suits your goals.

As this technology continues to evolve, who knows what innovations lie ahead? With every layer that’s printed, we move closer to a world where anything you imagine can become a tangible reality. So, are you ready to start creating? Happy printing!