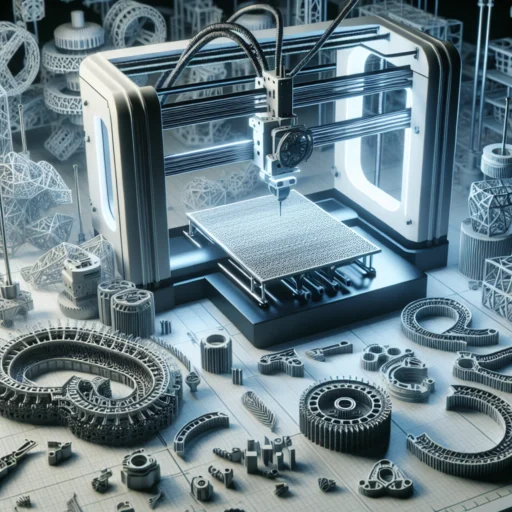

The Impact of 3D Printing on Custom Manufacturing

3D printing, once considered a futuristic wonder, is now a cornerstone of modern manufacturing. This technology, which builds objects layer by layer from digital designs, is transforming custom manufacturing in ways we couldn’t have imagined just a couple of decades ago. Whether it’s showing up in industries ranging from healthcare to aerospace or enhancing the hobbyist’s basement workshop, 3D printing is making waves, and the impact is profound.

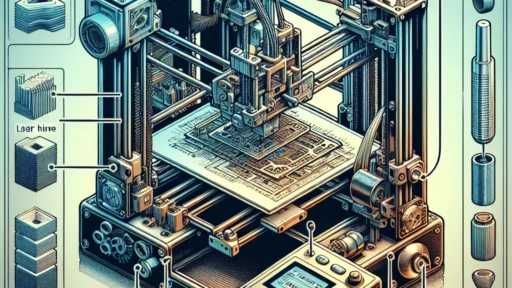

Revolutionizing Prototype Development

One of the biggest advantages of 3D printing is its ability to accelerate the prototyping process. Traditionally, creating a physical prototype could be cost-prohibitive and time-consuming. Designers would need to rely on tooling and molds, which often required significant investment and lead time. With 3D printing, designers can quickly produce detailed prototypes at a fraction of the cost. Imagine needing just a few iterations to iron out design kinks instead of lengthy wait times that could lead to lost opportunities. Rapid prototyping means companies can go from idea to market faster and more efficiently, allowing for greater innovation and adaptability in their product lines.

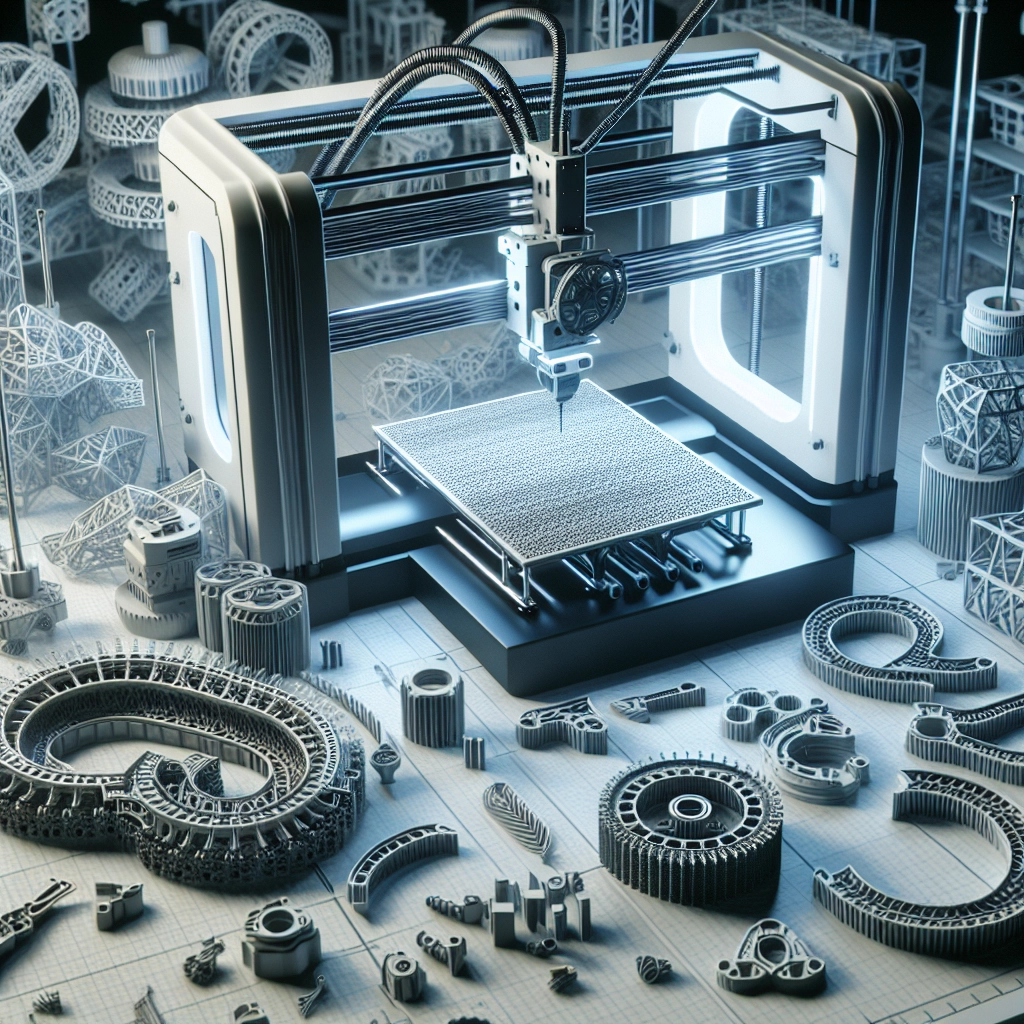

Customization Like Never Before

Gone are the days when "one-size-fits-all" ruled the manufacturing world. Today, customization is king, and 3D printing plays a vital role in this paradigm shift. With the ability to create objects tailored to individual specifications, customers can get exactly what they want. This has profound implications across different sectors.

Take the healthcare industry, for example. Medical professionals can now produce customized implants and prosthetics that fit a patient’s unique anatomy perfectly. This not only enhances comfort but also improves overall functionality. Additionally, consumers can access personalized products ranging from custom phone cases to bespoke jewelry designs. This level of personalization has turned consumers into co-designers, fostering a closer relationship between brands and their buyers.

Reducing Waste and Enhancing Sustainability

Sustainability is a hot topic these days, and for good reason. With growing concerns about our planet, 3D printing drastically reduces waste, effectively changing the narrative around manufacturing processes. Traditional manufacturing often entails subtractive processes, where materials are cut away to create a product, leading to significant material waste. 3D printing, however, is additive; it builds up from nothing, using only the material needed for the final product. This approach not only conserves resources but also enables the use of recycled materials and bioplastics, making it a more environmentally friendly option.

The Democratization of Manufacturing

One of the most intriguing effects of 3D printing is the democratization of manufacturing. Small businesses and even individuals can now step into the manufacturing arena without needing extensive resources or capital. Startups can create products with low upfront costs, allowing them to experiment and innovate in ways that were previously limited to larger corporations. The barrier to entry has all but vanished, fostering a vibrant ecosystem of makers, crafters, and entrepreneurs who can design and produce goods from their homes or small workshops. Makerspaces and community 3D printing hubs are popping up in cities around the globe, driving local innovation and creativity.

Challenges and Considerations

While the benefits of 3D printing are plenty, it’s important to acknowledge that the technology isn’t without its challenges. Intellectual property concerns are rising as more people gain access to design files and printing capabilities. There’s also the question of quality control and the standardization of 3D printed products, especially when safety is concerned—particularly in medical or aerospace applications.

Moreover, while 3D printing is fantastic for certain applications, it may not be the most efficient method for mass production. There are still scenarios where traditional manufacturing methods like injection molding might be more appropriate. The key is finding the right balance and knowing when to integrate 3D printing into the mix.

Looking Ahead

As advancements in materials and printing technologies continue to unfold, the future of custom manufacturing looks bright. We’re at the brink of a manufacturing revolution, one where flexibility, sustainability, and personalization can thrive. Industries that embrace these changes are likely to lead the charge in the coming years, pushing the boundaries of what’s possible with 3D printing.

In sum, 3D printing is not just a passing trend; it’s an unstoppable force reshaping how we think about manufacturing. Whether you’re a small business owner, an aspiring maker, or a curious consumer, the implications of this technology touch our lives in more ways than we may realize. Embracing this change could very well pave the way for a future where creativity and innovation know no limits.