The Importance of Bed Adhesion in 3D Printing

3D printing has transformed the way we think about manufacturing, prototyping, and creativity. Gone are the days when you needed expensive equipment or advanced skills to turn your ideas into tangible objects. With a 3D printer, anyone with a vision can bring their concepts to life. But there’s a crucial step in this process that can make or break your project: bed adhesion.

You might be wondering, "What exactly is bed adhesion, and why is it so important?" Let’s dive deep into the nitty-gritty of bed adhesion and why it serves as the foundation (quite literally!) for successful 3D printing.

What is Bed Adhesion?

At its core, bed adhesion refers to how well the first few layers of your print stick to the print bed. This is essential because if those initial layers don’t adhere properly, your print could warp, shift, or even fail entirely. Just imagine all that time, energy, and filament gone to waste because of poor bed adhesion—frustrating, right?

The print bed serves as the launchpad for your creation. A solid foundation helps ensure that your model remains stable throughout the printing process, allowing each layer to build upon the last. With proper bed adhesion, you can achieve cleaner lines, finer details, and an overall high-quality print.

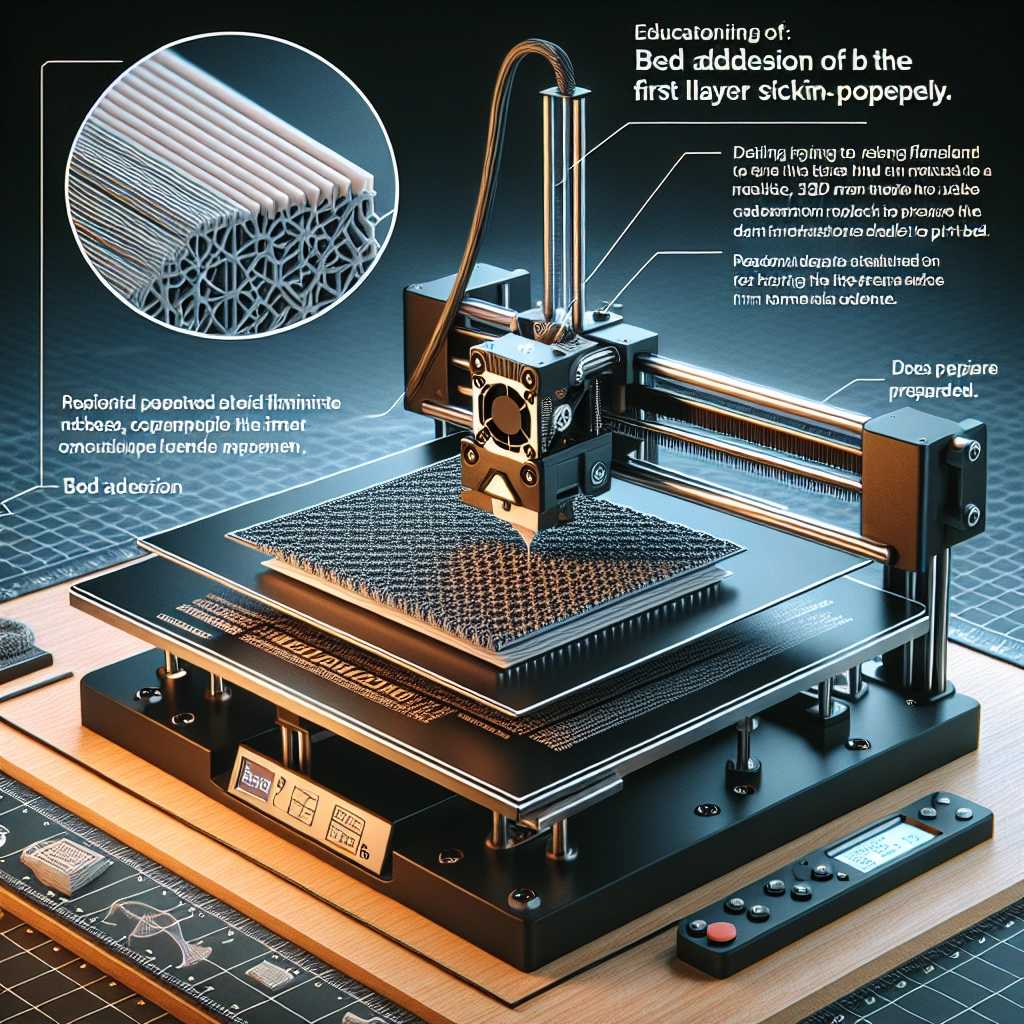

Factors Influencing Bed Adhesion

Several factors come into play when it comes to ensuring good bed adhesion. Let’s break them down a bit:

1. Print Surface Material

The type of print bed material can drastically affect bed adhesion. Common options include glass, aluminum, and various textured surfaces. Glass can be great for certain materials, while textured surfaces might work better for others. Experimenting with different surfaces is part of finding what works best for your specific 3D printer and project.

2. Temperature Settings

Another critical component is temperature. Most filaments have an optimal printing temperature range, and adhering to these recommendations can help your material bond better with the print bed. If your bed isn’t heated, you might notice that certain materials—like ABS—are more prone to warping. A heated bed can mitigate this issue and help keep the layers cozy and snug during the printing process.

3. First Layer Settings

Let’s not overlook the importance of the first layer! Adjusting your first layer height, speed, and extrusion settings can make a significant difference in how well the print adheres. Slowing down the first layer speed or increasing the extrusion will help squish that filament down better, leading to improved adhesion.

4. Filament Choice

Different filaments react differently to bed adhesion techniques. PLA is generally easier to work with compared to ABS, which might require some additional help, like using a glue stick or painter’s tape. Knowing the quirks and advantages of your filament can guide you in choosing the best bed adhesion method.

Bed Adhesion Techniques

Feeling a bit overwhelmed? Don’t worry; there’s a plethora of techniques you can try to improve bed adhesion. Here are a few popular methods:

-

Brims and Rafts: Adding a brim or raft helps create an extra layer of material around your print, increasing the surface area that sticks to the bed. This is particularly useful for models with small footprints.

-

Glue Sticks and Tape: Simple household items like glue sticks, blue painter’s tape, or even hairspray can work wonders for adhesion. A light coating on your print bed can help your print stick while also making cleanup a breeze.

-

Adhesive Sprays: For a more professional touch, consider using adhesive sprays specifically designed for 3D printing. They often provide reliable adhesion without the hassle of cleaning up afterward.

-

Leveling the Bed: Not to be overlooked, ensuring your print bed is level is crucial for achieving proper adhesion. An unlevel bed can lead to uneven extrusion and inconsistent adhesion.

The Bottom Line

Proper bed adhesion might seem like a small detail, but it can have a gigantic impact on your 3D printing success. Whether you’re creating prototypes, toys, or even intricate art pieces, ensuring that your prints stick correctly to the bed is foundational for both quality and efficiency.

So, the next time you set out to create something amazing with your 3D printer, don’t forget to pay attention to your bed adhesion. With the right techniques and a little practice, you’ll be churning out stunning prints in no time. Remember, each print is a learning experience, and with patience and persistence, you’ll find that perfect balance for your setup! Happy printing!