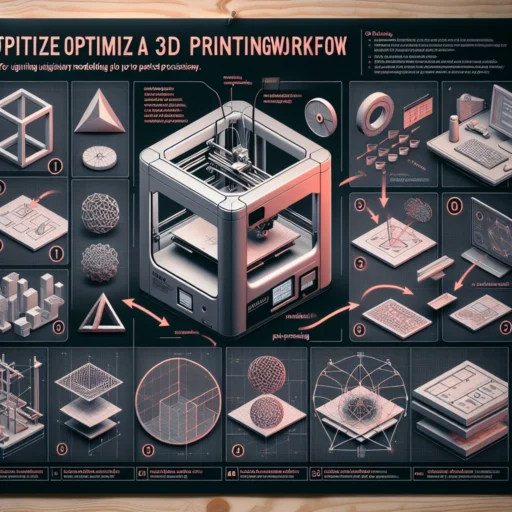

How to Optimize Your 3D Printing Workflow

3D printing has taken the world by storm! From creating intricate prototypes to crafting personalized gifts, it’s an incredible tool that can empower anyone, whether you’re a hobbyist or a seasoned pro. But as exciting as it is, the process can sometimes feel a bit overwhelming. Long print times, failed prints, and endless tuning can put a damper on your enthusiasm. Fear not! Here are some handy tips to help you streamline and optimize your 3D printing workflow, so you can focus more on creating and less on troubleshooting.

1. Start with a Good Model

The foundation of a great print is a solid digital model. Whether you’re designing your own or downloading from a repository, ensure that the model is well-optimized. Look for STL files that are manifold and free from errors. Software like Meshmixer or Netfabb can help you analyze and repair models if necessary. A clean model will significantly reduce print time and minimize the chances of failure.

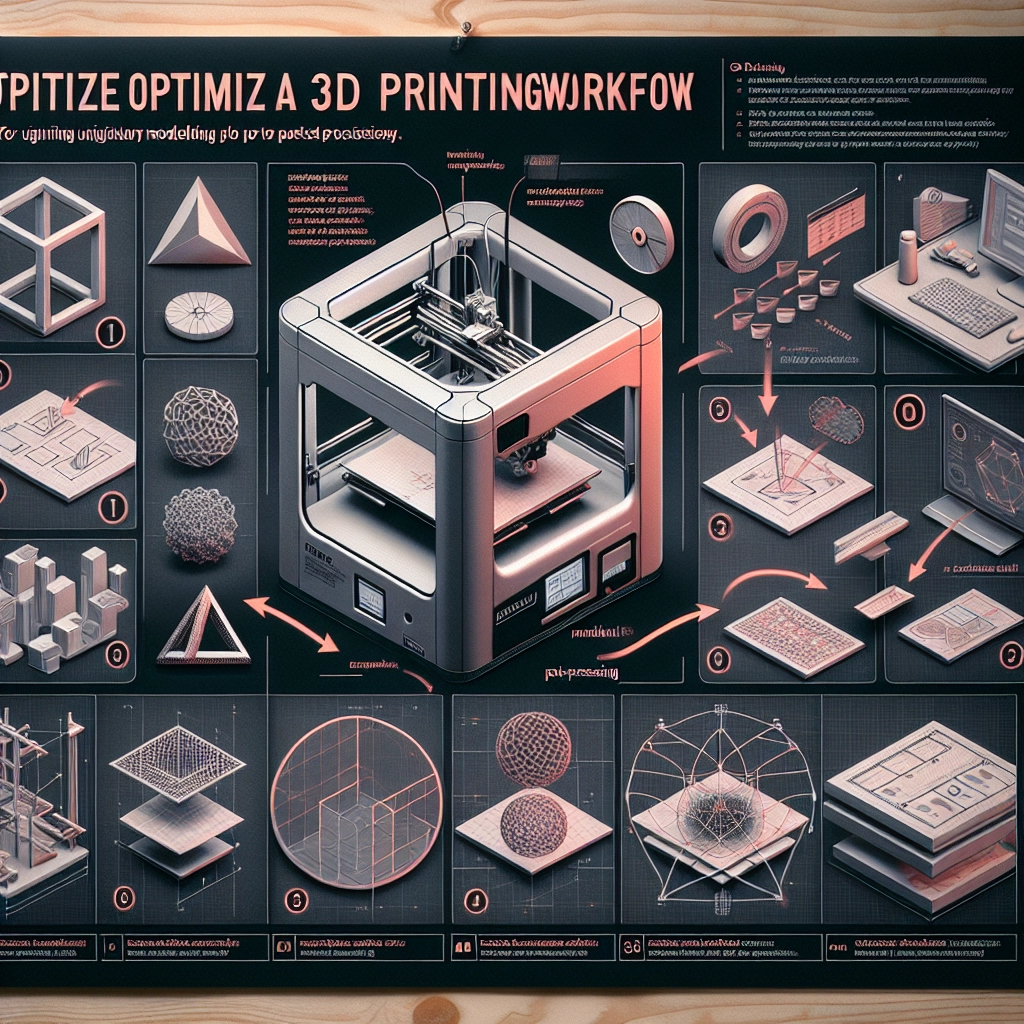

2. Choose the Right Settings

Every printer has its quirks, but finding the settings that work best for your specific model can make a world of difference. Spend some time experimenting with layer height, print speed, and infill density. Lower layer heights typically offer better detail but can increase print time, whereas higher speeds can compromise quality. Balancing these settings based on the purpose of your print will yield the best results.

3. Use a Reliable Slicing Software

Slicing software converts your 3D model into instructions your printer can understand. It affects everything from time to filament usage, so it’s essential to choose one that suits your machine and your skills. Programs like Cura, PrusaSlicer, and Simplify3D offer advanced features that can optimize prints, like adaptive layers and custom supports, not to mention some offer fantastic community support and tutorials to help you get the hang of the nuances.

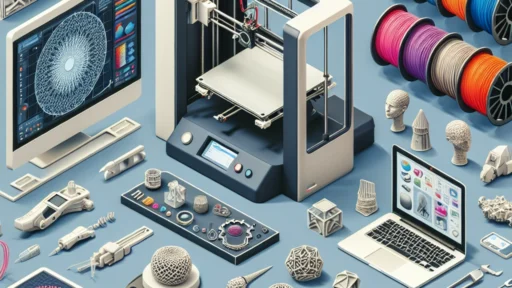

4. Maintain Your Printer

A well-maintained printer is a happy printer! Regularly check for wear and tear on belts, nozzles, and hot ends. Cleaning the nozzle prevents clogs, and ensuring guides and rails are free of dust and debris keeps things running smoothly. Also, lubricate moving parts as needed. This hands-on attention can greatly increase reliability and decrease the likelihood of failed prints.

5. Use Quality Materials

Not all filament is created equal. Investing in quality materials can greatly affect your results. Look for reputable brands and make sure you’re using the right filament for your project. Some materials, like PLA, are user-friendly and great for beginners, while others like ABS or PETG require more experience due to their different printing conditions, but they can produce durable, long-lasting prints.

6. Monitor Print Progress

Nothing’s worse than walking away from a print only to come back to a tangled disaster! Consider setting up a camera or using a monitoring tool. Some printers even come with built-in Wi-Fi capabilities that allow you to check prints remotely. This can save you heartache and material as you’ll have a better chance of catching issues before they turn into print failures.

7. Utilize Print Profiles

Once you find a successful configuration for a particular material and design, save that as a print profile. This will create a workflow that allows for quick access to optimized settings wherever you need them. Over time, you’ll compile a library of profiles that work wonders for whatever project comes your way, making future prints much more efficient.

8. Keep Things Organized

Last but certainly not least, organization is crucial! From keeping your digital files organized in folders to having a neat workspace, everything should have its place. A cluttered environment can lead to distractions and mistakes, not to mention it can make it harder to find that perfect filament or tool when you need it.

Embrace the Learning Curve

3D printing is as much about creativity as it is about technique. Each print is an opportunity to learn. Optimizing your workflow isn’t just about speeding things up; it’s about discovering what works best for you and your projects. With each layer you print, you’ll grow not only as a maker but also as a problem solver. So keep experimenting, keep pushing your boundaries, and most importantly, keep enjoying the process. Your next awesome creation is just a print away!