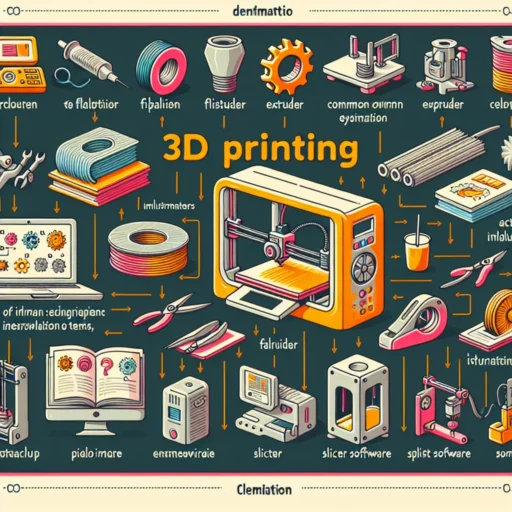

Understanding 3D Printing Terminology: A Glossary for Enthusiasts

Welcome to the exciting world of 3D printing! If you’re new to this innovative technology, you might find yourself a bit overwhelmed by the jargon. But fear not! Whether you’re looking to print your first object or interested in the finer details of additive manufacturing, this glossary will help clear things up. So, let’s dive in!

1. Additive Manufacturing

At the heart of 3D printing is the term "additive manufacturing." This refers to the process of creating an object by adding material layer by layer. Unlike traditional manufacturing methods, which often involve subtracting material from a larger block, additive manufacturing builds up the desired shape, which can lead to less waste and often more complex designs.

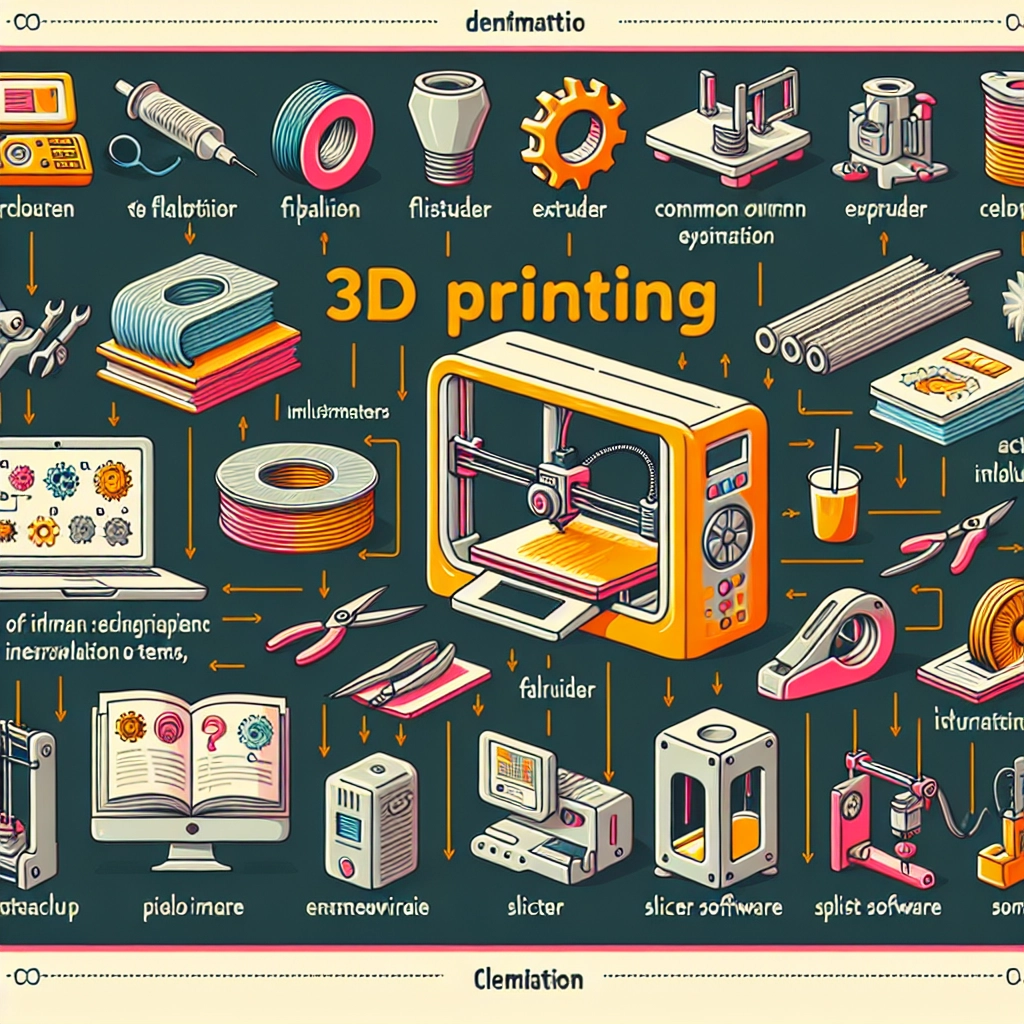

2. Filament

This is the material used in FDM (Fused Deposition Modeling) printers—think of it as the "ink" for your 3D printer. Filaments come in various types, with the most popular being PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene). Each filament type has its own properties, influencing how projects turn out.

3. Slicing Software

Before your model can be printed, it needs to be converted into a format that the 3D printer understands. This is where slicing software comes into play. It takes your 3D model (usually in STL or OBJ format) and divides it into thin horizontal layers, creating a set of instructions for the printer. Popular slicing programs include Cura and Simplify3D.

4. STL File

An STL file is a common file type used for 3D printing. It stands for "Stereolithography" and contains a representation of a 3D object in a format that slicing software can read. When creating designs, you’ll likely export your final model as an STL file to prepare for printing.

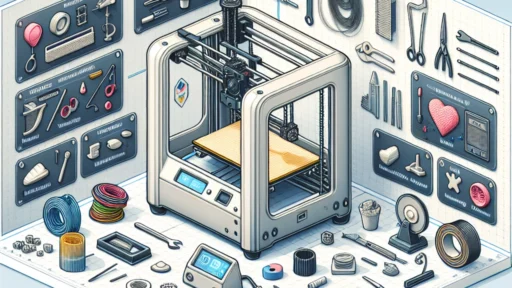

5. Extruder

The extruder is a vital component of FDM 3D printers. It heats up the filament and then pushes it through a nozzle to create the layers of the object. Extruder design can affect print quality, speed, and even the types of filaments you can use.

6. Bed Adhesion

This term refers to how well your print sticks to the printing bed. Good bed adhesion is crucial; otherwise, your object might warp or detach during the printing process. There are various techniques and materials for improving bed adhesion, such as using a heated bed, applying glue, or sticking down a layer of blue tape.

7. Resolution

Resolution in 3D printing refers to how finely the printer can create details in the object. Measured in microns, a lower number indicates a higher resolution. While high resolution can produce detailed prints, it often comes at the cost of increased print time. So, it’s a balancing act based on what you’re creating!

8. Post-Processing

Once your print is complete, there may still be some work to do. Post-processing involves any steps taken to finish your print after it comes off the printer. This can include sanding, painting, or assembling multiple components. It’s a chance to add that final touch of polish to your creation.

9. Supports

When printing complex models, you might need to use supports. These are temporary structures made from the same or different material that hold up overhanging parts of the model during printing. Once the print is complete, you can remove these supports for a cleaner look.

10. Resin

For those using SLA (Stereolithography) printers, resin is the material of choice. Unlike filament, resin is a liquid that hardens when exposed to UV light. This process allows for highly detailed prints, but it also requires careful handling since resin can be toxic and messy.

11. Calibration

Before you start printing like a pro, you need to calibrate your printer. Calibration involves adjusting various settings—like bed level and extruder temperature—to ensure the printer produces the best possible results. It might feel tedious, but trust us; it’s worth the effort!

12. Print Speed

This is how fast your printer deposits filament or cures resin, measured in millimeters per second (mm/s). Higher print speeds can reduce time but may compromise print quality. Finding the sweet spot for your specific project and printer is essential to achieving great results.

Exploring the world of 3D printing can be a thrilling adventure. By familiarizing yourself with these terms, you’re on your way to mastering the basics of this transformative technology. As you continue to learn and experiment, keep in mind that 3D printing is not just about the final product; it’s about enjoying the process of creation. Embrace the trial-and-error journey, and don’t hesitate to connect with fellow enthusiasts who share your passion. Happy printing!