A Guide to Troubleshooting Common 3D Printer Issues

3D printing has revolutionized the way we think about design and manufacturing. Whether you’re a novice tinkerer or a seasoned pro, there’s nothing quite like watching your digital creations come to life layer by layer. But, as with any technology, things can get a little tricky sometimes. If you’ve found yourself staring at a tangled mess of filament or a crooked print, you’re certainly not alone. Fear not! Let’s dive into some common 3D printer issues and their straightforward solutions.

1. Print Not Sticking to the Bed

Ah, the classic. Your print starts but quickly peels away from the print bed like it’s auditioning for a role in a dramatic soap opera. This issue often stems from improper bed adhesion, and there are a few things you can do to encourage that print to stay put.

-

Level the Bed: First off, ensure that your print bed is properly leveled. A good rule of thumb is that a piece of paper should fit snugly between the nozzle and the bed without too much resistance.

-

Adjust the Temperature: If you’re using PLA, for instance, check that your bed temperature is set between 50-60°C. Different materials have different requirements, so check the specs for what you’re using.

-

Use Adhesives: Sometimes, a little extra help is needed. From glue sticks to specialized 3D printing adhesives, applying a thin layer can significantly improve stickiness.

2. Strings and Oozing

This is the spaghetti monster of the 3D printing world. If you find thin strands connecting parts of your print, you’re dealing with unwanted stringing.

-

Retraction Settings: This is where tweaking your retraction settings plays a game-changing role. Increasing the retraction distance or speed can significantly reduce the risk of stringing.

-

Temperature Check: Lowering your nozzle temperature can help as well. When the filament is too hot, it can ooze out more easily. Experiment with settings to find that sweet spot!

3. Layer Misalignment

So you’ve got a beautiful design, but it appears your printer decided to throw the print party a little skewed. Layer misalignment can happen for several reasons, and it’s often the result of mechanical issues.

-

Check Belts and Pulleys: Make sure all your belts are tight and your pulleys are secure. Loose belts can lead to misalignment, so adjust them as necessary.

-

Motor Issues: If your stepper motors are obstructed or not functioning correctly, you may notice layer misalignment. Check for debris or any strange noises coming from your printer that might indicate a mechanical issue.

4. Under-extrusion

Under-extrusion makes it seem like your printer is on a diet—your prints come out with gaps or weak structures.

-

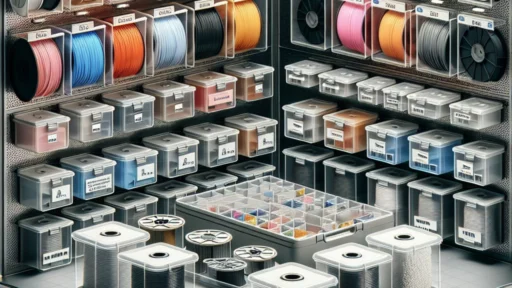

Check Filament: Ensure you’re using good quality filament. Cheap or old filament can become moisture-laden or brittle, leading to inconsistent printing.

-

Extruder Settings: Check your extruder settings as well. If the temperature is too low, the filament might not melt properly. Increase the temperature slightly and see if it helps.

-

Clog Inspection: Lastly, inspect your nozzle for any clogs. Use a cleaning needle or a needle to clear any blockages that might be inhibiting proper flow.

5. Failed Prints

Nothing is more disheartening than dedicating hours to a print only to find it has failed, often partway through. While thoroughly frustrating, troubleshooting can help salvage the situation or prevent it in the future.

-

G-code Issues: Always double-check your G-code. Use slicing software that’s well-suited to your printer and ensure settings align with your machine’s capabilities.

-

Temperature Fluctuations: Abnormal temperature changes can cause prints to fail mid-process. Ensure your printer is in a stable environment away from drafty windows or heat sources.

-

Material Quality: Sometimes the issue stems from the filament itself. Ensure it’s fresh and properly stored to avoid moisture absorption.

Final Thoughts

3D printing can sometimes feel like an art form and a science experiment all rolled into one, and encountering issues is part and parcel of the adventure. The good news? With a bit of patience and troubleshooting, you can solve these common problems and watch your creations flourish. Each fix brings you one step closer to mastering your 3D printer, so embrace the learning journey and remember, even the most seasoned pros encounter hiccups along the way. Keep experimenting—every layer you print is a step toward your ultimate masterpiece!