The Science Behind 3D Printing: How It Works

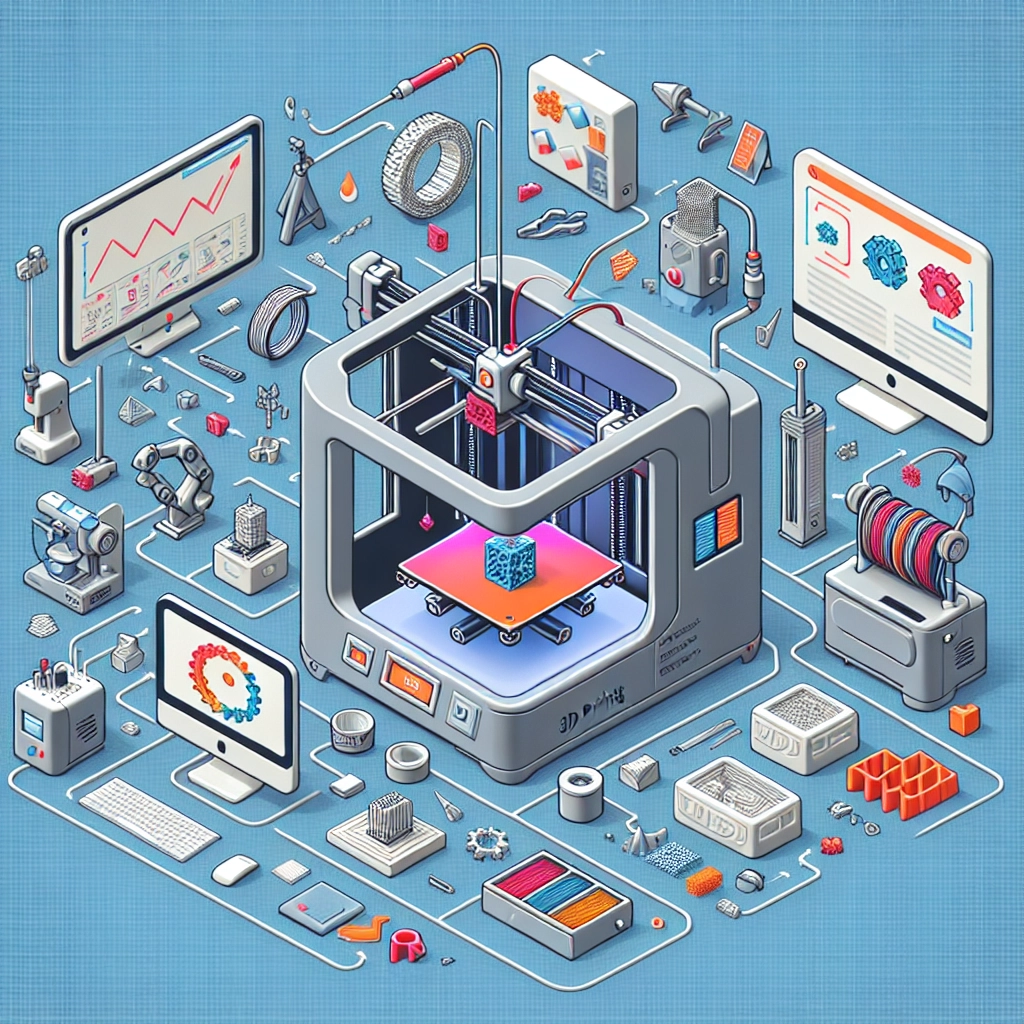

Ah, 3D printing! It seems like every time we turn around, there’s another mind-blowing story about something incredible being created with this amazing technology. From custom prosthetics to houses built layer by layer, 3D printing is transforming industries in ways we never thought possible. But have you ever wondered how this fascinating process actually works? Let’s dive into the science behind 3D printing and discover what goes on behind the scenes.

What is 3D Printing?

At its core, 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. Unlike traditional manufacturing methods that involve cutting away material (subtractive manufacturing), 3D printing builds objects layer by layer. This approach not only allows for more complex designs but also reduces waste, making it an appealing option for many applications.

The Basics of 3D Printing Technology

The 3D printing process begins with a digital 3D model. This model can be created using computer-aided design (CAD) software or 3D scanning technology. Once you have your design ready, it’s time for the magic to happen!

Step 1: Slicing the Model

The first step after finalizing the 3D model is to prepare it for printing. This is where slicing software comes into play. The slicing software takes the 3D model and breaks it down into hundreds or thousands of layers, creating a set of instructions—often called G-code—that tells the 3D printer how to recreate the object layer by layer. Think of it like a recipe: each layer corresponds to a specific step that needs to be followed to achieve the final result.

Step 2: The Printing Process

Once the slice file is ready, it’s time to load it into the 3D printer. Different types of 3D printers use various methods to create objects. Here are a few of the most common techniques:

-

Fused Deposition Modeling (FDM): This is the most popular 3D printing technology, especially for hobbyists. An FDM printer melts thermoplastic filament and extrudes it through a heated nozzle. As the nozzle moves around, it lays down the melted filament layer by layer, allowing it to cool and solidify.

-

Stereolithography (SLA): This technique uses ultraviolet (UV) light to cure liquid resin into solid plastic. An SLA printer projects a laser onto a vat of resin, hardening it layer by layer. The result is often a smoother finish and more intricate details compared to FDM.

-

Selective Laser Sintering (SLS): SLS works by using a laser to fuse powdered material—commonly nylon—into solid structures. The laser scans and sinters the powder, creating a solid layer. This method is great for creating functional parts and prototypes because it produces durable and high-strength components.

Step 3: Post-Processing

After the object is printed, there’s usually a post-processing phase. This can involve removing support structures (for more complex prints), sanding, or painting the object to achieve the desired finish. For SLA prints, extra curing under UV light may be required to ensure the material reaches its full strength.

The Impact of 3D Printing

Now that we’ve covered the basics, you might be wondering how this technology is impacting various industries. The applications of 3D printing are vast and varied! In healthcare, for example, it’s being used to create personalized implants and prosthetics tailored to the patient’s exact anatomy. In aerospace and automotive industries, companies are crafting lightweight parts that reduce fuel consumption. And let’s not forget about education, where students are exploring engineering concepts through hands-on projects fresh out of the printer.

3D printing is revolutionizing how products are designed and created. It offers unparalleled customization and rapid prototyping, allowing businesses to bring their ideas to life faster and more affordably than ever.

The Future of 3D Printing

As technology continues to advance, the possibilities for 3D printing are exciting. From bioprinting organs to constructing entire buildings, the future holds endless opportunities for innovation. With sustainability at the forefront of many minds, the ability to print with recycled materials opens new avenues to reduce waste in manufacturing.

Ultimately, the science behind 3D printing is just beginning to unfurl. It’s clear that this technology is more than just a trend; it’s a game-changer that is reshaping our world. As we continue to explore its potential, it’s fascinating to think about how many of our everyday items might someday come from a 3D printer. Who knows? The next time you pick up a small gadget or a beautiful piece of art, it might just have been brought to life layer by layer in a workshop not too far from you. The future is undoubtedly here, and it’s being printed in three dimensions!