3D Printing with Flex Filaments: What You Should Know

If you’ve dipped your toes into the world of 3D printing, you’ve probably stumbled upon a plethora of materials that can be used to create everything from intricate models to practical tools. One category that has gained traction in recent years is flexible filament, or “flex filaments.” These materials are unique and offer a whole new realm of possibilities for makers and hobbyists alike. So, what do you need to know about 3D printing with flex filaments? Let’s dive in!

What Are Flex Filaments?

Flex filaments are materials designed to be elastic and rubbery, allowing your printed objects to bend and withstand stress without breaking. Common types of flex filaments include Thermoplastic Polyurethane (TPU) and Thermoplastic Elastomer (TPE). They can be used for creating items such as phone cases, wearable accessories, custom gaskets, and toys that require some flexibility—essentially anything that benefits from a bit more give.

Benefits of Using Flex Filaments

Versatility

One of the most exciting aspects of flex filaments is their versatility. You can create both soft, squishy items and denser parts that maintain their shape. This material choice opens the door to a wide range of applications. Need a custom-sized shoe insert or a phone case that cushions your device? Flex filaments have you covered.

Enhanced Durability

Unlike more brittle filaments like PLA, flexible filaments are resistant to impacts and can handle some level of deformation without snapping. This makes them ideal for products that require longevity and toughness, along with a touch of elasticity.

Vibrant Finishes

Many flex filaments come in bright and vibrant colors, allowing you to add personality to your creations. You can even find glow-in-the-dark options that can add a playful element to your printed models.

Challenges with Flex Filaments

While flex filaments are fantastic, they do come with their own set of challenges that you’ll need to navigate.

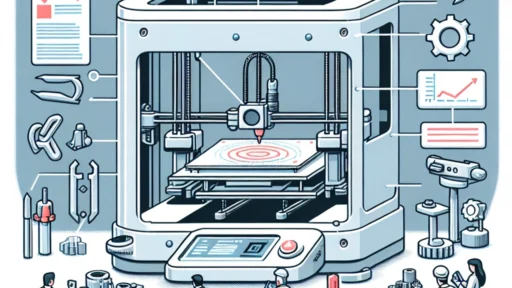

Print Settings

Getting the correct print settings is crucial when working with flex filaments. You may find that the standard settings you use for rigid materials like PLA don’t translate well. You’ll need to lower your print speed, adjust the temperature, and ensure you have adequate retraction settings to prevent jams.

Extruder Compatibility

Not all printers are created equal. Many standard extruders may struggle with flex filaments due to the way they handle filament feeding. If you have a direct-drive extruder, you’re in luck! These setups have an easier time pushing flexible materials through the nozzle. If you’re using a Bowden extruder, you might run into issues with feeding, so be prepared to make some adjustments.

Stringing and Warping

During the printing process, you may notice some stringing or warping with flexible filaments, especially if the temperature is too high. Finding the right balance through trial and error can help improve your print quality, but it may take some patience as you stumble through the learning curve.

Tips for Working with Flex Filaments

Start with Smaller Prints

If you’re new to using flex filaments, it’s wise to start with smaller prints before tackling more complex designs. This will help you get a feel for material behavior without investing too much time or filament.

Test and Tune Your Settings

Don’t be afraid to experiment! Calibrate your printer settings incrementally, adjusting temperature, speed, and retraction until you find the sweet spot for your specific filament. It’s a game of trial and error, but the payoff is worth it when you get that perfect print.

Use a Quality Nozzle

Consider using a hardened steel nozzle, especially if you’re working with abrasive flex filaments. This upgrade can prolong the lifespan of your nozzle and ensure smoother filament flow.

Store Properly

Flex filaments can absorb moisture from the air, which may negatively affect print quality. Store them in airtight containers with desiccants to keep them in pristine condition for future projects.

With a touch of creativity and some experimentation, you’ll find that flex filaments can truly elevate your 3D printing game. From pragmatic everyday items to fun and unique designs, the possibilities are limited only by your imagination. So gather your materials, tinker with those settings, and get ready to explore a vibrant, flexible new world of 3D printing!