Getting Started with Resin 3D Printing: A Guide

3D printing has taken the world by storm, and among the various methods available, resin printing has gained a dedicated following for its ability to create stunningly detailed and intricate models. If you’re looking to dive into the fascinating world of resin 3D printing, buckle up! This guide will provide you with everything you need to get started on your creative journey.

What is Resin 3D Printing?

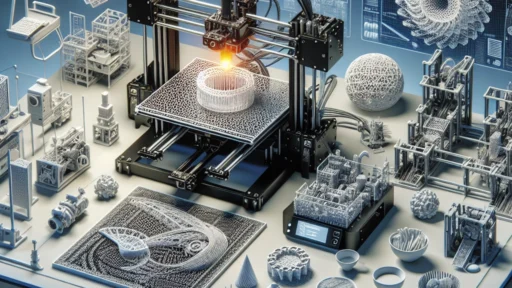

Resin 3D printing is a method that uses photosensitive resin, which hardens when exposed to ultraviolet (UV) light. This process is often termed Stereolithography (SLA) or Digital Light Processing (DLP). Unlike traditional filament-based 3D printing, which extrudes plastic filament layer by layer, resin printing cures layers of liquid resin one at a time, resulting in remarkably smooth finishes and intricate details. This is especially popular among hobbyists creating miniatures, jewelry, and prototypes.

Choosing the Right Printer

If you’re new to resin printing, choosing the right printer can feel overwhelming with all the options available. Here are a few considerations to keep in mind:

-

Print Volume: Depending on what you plan to create, consider the build size. If you’re primarily printing small figures or intricate designs, a printer with a smaller build volume will typically suffice.

-

Printer Type: Most entry-level resin printers will fall into SLA and DLP categories. SLA printers often shine in detail and can handle a variety of resin types, while DLP printers tend to print faster due to using a digital light source to cure an entire layer at once.

-

Price: Resin printers are available at various price points. Entry-level printers can start from under $200, while more advanced machines can cost thousands. Consider your budget and how invested you are in this new hobby.

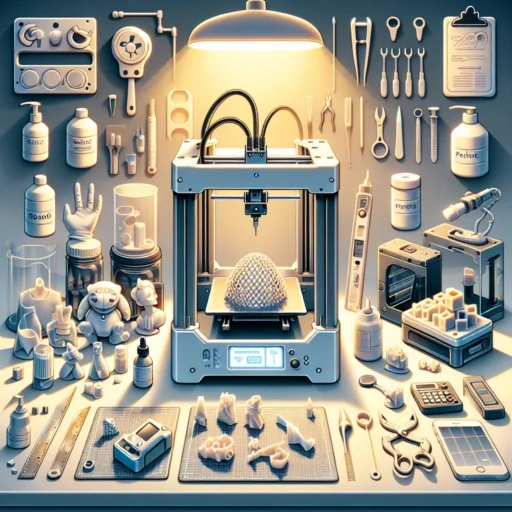

Essential Supplies

Once you have your printer, you’ll need a few essential supplies to get started:

-

Resin: Choose a good quality resin suitable for your printer model. There’s a plethora of options, including standard, flexible, and high-detail resins. Don’t forget to check the manufacturer’s recommendations!

-

Cleaning Supplies: Resin can be messy, so having gloves, paper towels, and possibly a dedicated wash station will help keep your workspace tidy. Isopropyl alcohol (IPA) is commonly used for cleaning prints.

-

Curing Station: After printing, parts will require curing under UV light. Many hobbyists create DIY curing stations, while manufacturers also sell dedicated curing units.

-

Safety Gear: It’s important to prioritize safety when working with resin. Make sure to have gloves, goggles, and a mask to protect yourself from any fumes. Proper ventilation is also key—work in well-ventilated spaces or invest in a fume extractor.

Preparing Your Model

Before printing, you’ll want to prepare your model in software. Most 3D resin printers come with slicing programs, which convert your model into a format the printer can understand. Common software includes Chitubox, Lychee Slicer, and PrusaSlicer. Here’s what to remember:

-

Orientation: The way your model is oriented can greatly affect print success. Angling your model can help minimize the use of support structures and improve finish.

-

Supports: Most prints will need support as resin can sag during printing. The slicing software often includes auto-support features, but manual adjustments can lead to better results.

-

Slice Settings: Experiment with layer height and exposure times. Thin layers (around 0.05-0.1mm) typically yield better detail but take longer to print. Refer to your resin’s guidelines for optimal exposure settings.

Printing and Post-Processing

Now it’s time to hit that print button! Watch as your printer works its magic—there’s something incredibly satisfying about seeing your design come to life layer by layer.

Once the print completes, it’s not over just yet. After removing the model from the printer, rinse it in IPA to remove excess resin and prevent any uncured material from marring your print. After rinsing, proceed to cure your model in UV light, which enhances the material’s strength and detail.

Experiment, Learn, and Have Fun!

As you dive deeper into resin 3D printing, you’ll surely make mistakes along the way—it’s all part of the learning process. Don’t hesitate to experiment with different design choices, resin types, and print settings. Join online communities, watch tutorials, and share your experiences; this is a vibrant and passionate community ready to help you succeed.

With patience and practice, resin printing can unlock your creative potential, allowing you to produce unique pieces that can be cherished or showcased. Happy printing!