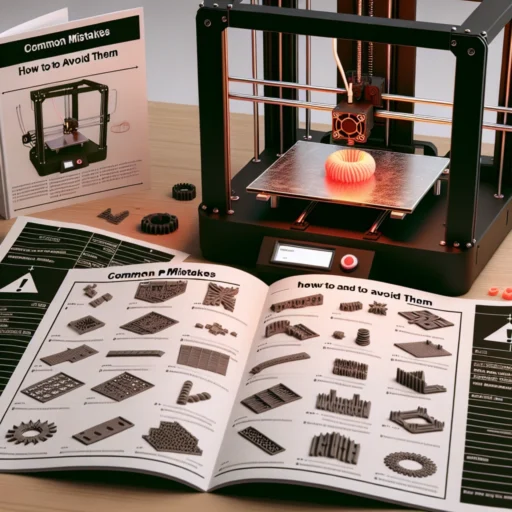

3D Printing Failures: Common Mistakes and How to Avoid Them

3D printing is like having a mini-manufacturing plant right in your home or workspace. The excitement of bringing your imagination to life layer by layer is a thrill that many enthusiasts cherish. But anyone who has ventured into the world of 3D printing knows that the road to a perfect print can be a bit bumpy. It’s easy to run into a host of problems along the way, but don’t let that discourage you! Understanding common mistakes can make all the difference, helping you produce stunning, reliable prints. Let’s dive into some of the most prevalent 3D printing problems and how to navigate them like a pro.

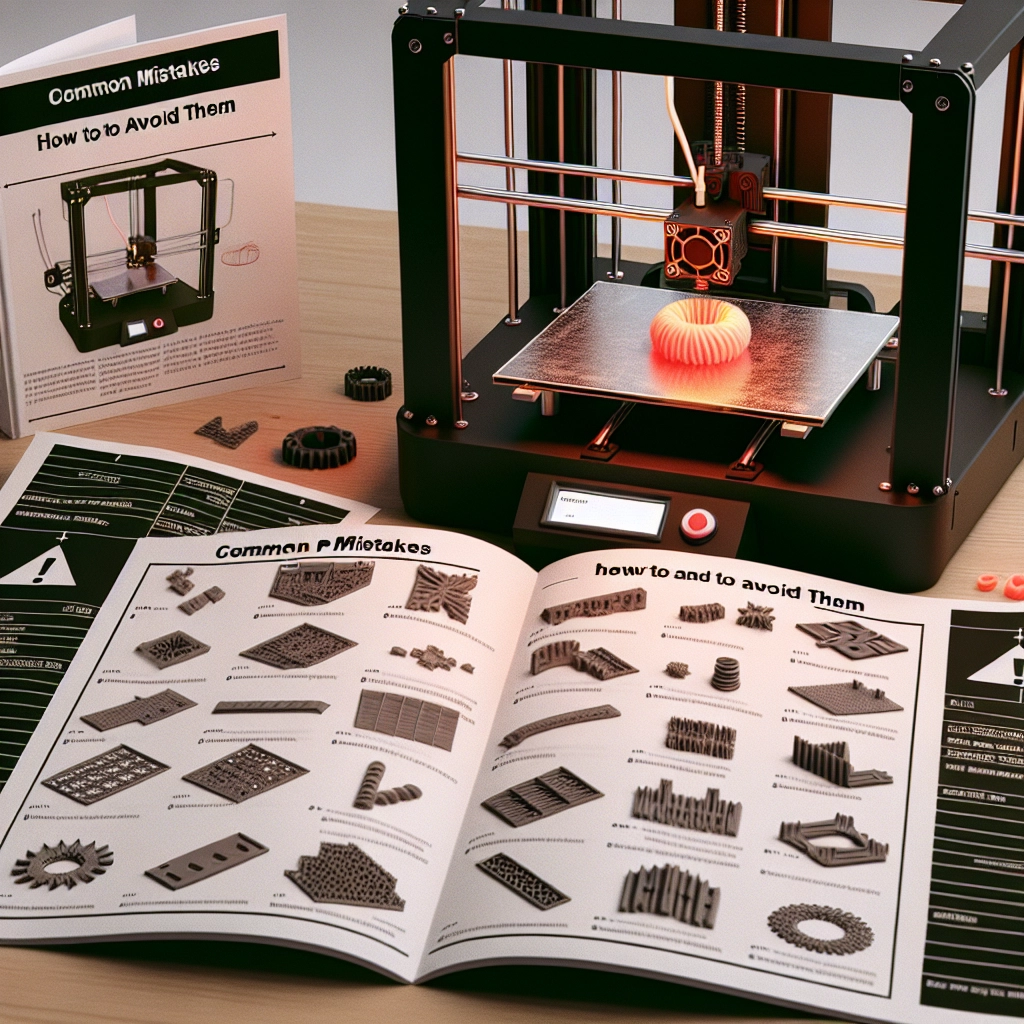

1. Bed Adhesion Issues

One of the most frustrating issues new 3D printers face is trouble with bed adhesion. You may find your designs curling or detaching from the print bed, which can lead to a real mess.

How to Avoid It:

To achieve that all-important first layer, ensure that your print bed is perfectly leveled. Many printers come with auto-leveling features these days, but if your model doesn’t, you might have to manually adjust it. Additionally, applying a thin layer of glue stick, blue painter’s tape, or even hairspray can help improve adhesion. Just remember to clean the bed regularly to avoid dust build-up!

2. Stringing and Oozing

Ever pulled a piece out of the printer only to find nasty webs of filament hanging off of it? That’s stringing, and it’s a common issue that can ruin an otherwise fabulous print.

How to Avoid It:

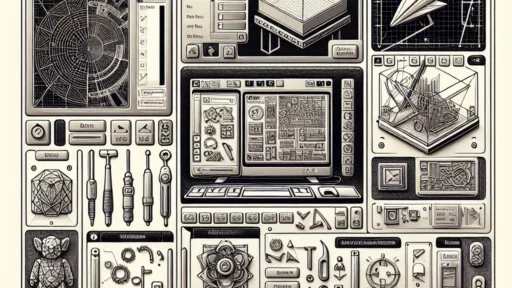

To combat this pesky problem, try adjusting your retraction settings in your slicer software. Increasing the retraction distance can help minimize oozing while allowing your print nozzle to move more smoothly. Lowering the printing temperature can also minimize stringing since the filament will flow less freely. You might also consider enabling “combing mode” to keep the nozzle within the bounds of your filament’s previous path.

3. Inconsistent Layer Heights

When your print starts to look like it’s going up and down in height, it’s not an art piece—it’s a problem! Inconsistent layer heights can lead to an unsightly finish and structural issues.

How to Avoid It:

This often occurs due to a worn or damaged Z-axis lead screw or an improperly aligned X and Y axes. First, make sure your printer’s axes are properly calibrated. Regular maintenance should include checking for wear, tightening loose parts, and cleaning the lead screws. A well-maintained printer is a happy printer!

4. Warping

Nobody likes a warping print! This happens when corners of your print start lifting off the bed, leading to a totally botched job. Warping is particularly common when using materials like ABS.

How to Avoid It:

To reduce warping, you may want to try a heated bed, which can keep the base of your print warm and prevent quick cooling. Additionally, using an enclosure for your printer can help maintain a consistent temperature around your print. For stiffer materials, consider sticking with PLA, which is much less prone to warping.

5. Clogs and Jamming

Nothing halts a printing session like a pesky clog! Your filament can get jammed in the hot end, causing a frustrating interruption in your work.

How to Avoid It:

Regular cleaning of your nozzle and ensuring you’re using quality filament will minimize the chances of jams. A common trick is to perform a cold pull, where you heat up the nozzle, pull the filament out, and, as it pulls away, it brings debris with it. Also, keep a close eye on your filament diameter to ensure it’s consistent and not leading to clogs.

6. Poor Print Quality

Finally, let’s talk about those prints that just come out looking drab. Poor print quality can stem from various issues, including incorrect settings, bad filament, or subpar calibration.

How to Avoid It:

Pay attention to your slicer settings, and ensure you’re using the correct parameters for the specific filament type. Experiment with print speeds; sometimes slowing down can result in a smoother finish. And of course, using higher-quality filament can genuinely elevate your print game.

With these tips in your back pocket, you’re well on your way to turning 3D printing frustrations into glorious successes! Each hiccup along the way is an opportunity for learning—after all, every expert was once a beginner. Embrace the journey, enjoy the process, and remember that persistence pays off. Your next print could just be the masterpiece you’ve been dreaming about!