Best Practices for 3D Printing Complex Designs

If you’re diving into the world of 3D printing—especially with intricate or complex designs—you’re in for an exciting ride! From creating beautiful art pieces to engineering prototypes, the possibilities are endless. But navigating the intricacies of 3D printing can feel a bit overwhelming at times. Fear not! Here are some best practices to help you tackle those complex designs like a pro.

Understand Your Model

Before hitting that print button, it’s vital to understand your 3D model. Look it over closely. Is it a multi-part design? Are there moving components? Complex designs often come with their own set of challenges, so you’ll want to familiarize yourself with the ins and outs of your creation. Use your slicer software to view the layer breakdown—it can provide important insights into how the printer will interpret each segment.

Choose the Right Material

When it comes to materials, it’s not a one-size-fits-all scenario. Different types of filament have unique properties that can significantly impact the outcome of your print. For example, if your design has intricate details, you might want to consider PLA (Polylactic Acid) for its ease of use and reliable print quality. On the other hand, if you’re looking for durability and flexibility, ABS (Acrylonitrile Butadiene Styrene) or PETG (Polyethylene Terephthalate Glycol) might be better suited to your project.

Also, don’t overlook specialty filaments like TPU for flexibility or polycarbonate for strength. It’s worth experimenting to find which material works best for your specific design.

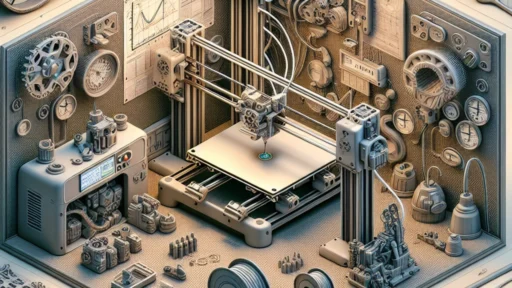

Optimize Your Settings

Every intricate model deserves a customized approach when it comes to printing settings. Pay attention to layer height—lower heights (like 0.1mm instead of 0.2mm) can provide finer detail but will take longer to print. Adjusting the print speed is also crucial; slower speeds often yield better results for complex designs, especially those with lots of overhangs or small details.

Temperature settings also play an important role. A temperature that’s too high can lead to warping or stringing, while one that’s too low may not allow for proper adhesion. Keep a close eye on the balancing act that is print temperature.

Support Structures are Your Friend

With complex designs, support structures can make a significant difference in print success. They hold up parts of your design that might not be able to stand on their own, especially overhangs and bridges. Many slicer software programs offer automated support generation, though it’s worth checking the orientation of your model to minimize the need for supports where possible.

When adding support, look for smart options that are easy to remove post-printing, and explore various support styles in your slicer. Breakaway supports or tree supports might give you cleaner finishes in some cases.

Embrace Orientation

The orientation of your model when you print can greatly influence the strength and detail of the final product. Testing out various angles and positions can lead to improved prints. Sometimes, rotating the model even slightly can make a big difference in how it handles stress and appears visually.

Don’t forget to take into account the direction of the filament flow; it can affect the strength of each layer. Experimenting with your model’s position in the print bed may enhance its durability and aesthetics.

Post-Processing for Perfection

Once you’ve successfully printed your complex design, the fun isn’t entirely over. Post-processing can elevate your print from good to great. This could include sanding, painting, or even hydro-dipping for a unique finish.

Pay attention to how you treat each section of your model, especially if it has intricate details. Getting into tight spaces with sandpaper can be tricky, so tools like files or rotary tools can come in handy for those hard-to-reach areas.

Learn from Each Print

Finally, don’t forget that every print, successful or not, is a learning opportunity. Keep a log of what worked and what didn’t for future reference. Each design brings its own set of challenges, and your experience will only make you a better printer.

3D printing complex designs is an art as much as it is a science—a balance of creativity, technical skill, and a touch of patient experimentation. Embrace the journey, learn from setbacks, and soon you’ll find yourself crafting intricate designs with confidence and flair. Happy printing!