The Future of 3D Printing: Trends That Will Shape the Industry

Isn’t it fascinating how 3D printing has transformed from an experimental technology in the 1980s to a pivotal force in manufacturing, healthcare, and even education? What started as a novelty is now being embraced by a diverse range of industries, and the future looks even more exciting. Let’s dive into some trends that are set to shape the future of 3D printing and explore what they might mean for all of us.

Advanced Materials

One of the most significant trends in 3D printing is the continuous development of advanced materials. Gone are the days when plastic was the only game in town. Today, there’s an impressive array of materials, from flexible polymers to metals and even bio-inks for printing living tissues. Innovations like carbon fiber composites and metals such as titanium and aluminum are being used to create stronger and lighter products—think aerospace engineering or high-performance automotive parts.

In the realm of healthcare, bio-printing is making waves, with researchers experimenting to print human organs—imagine a future where waiting for a transplant might be a thing of the past! As material science keeps evolving, we can expect to see even more options that enhance both function and aesthetic.

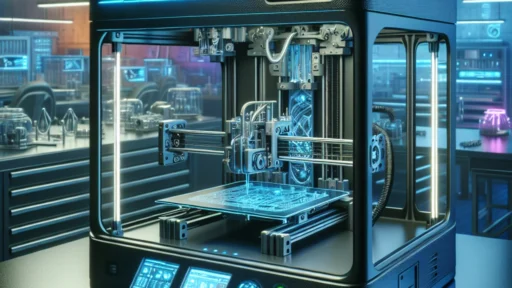

Automation and AI

The integration of automation and artificial intelligence (AI) with 3D printing is another transformative trend on the horizon. Imagine a world where quality control during the printing process is managed by intelligent systems that learn and adapt. These systems would optimize the printing process in real-time, ensuring consistency and reducing waste.

Moreover, AI can also enhance the design phase; generative design applications can create models that are not only aesthetically pleasing but also structurally sound, all while saving time and resources. This technology could be instrumental in fields like architecture and product design, where efficiency and innovation go hand-in-hand.

Customization and Personalization

As consumers increasingly seek individuality, the demand for customization and personalization is more pronounced than ever. 3D printing is tailor-made for this trend, allowing users to produce unique products based on their specific needs or preferences. Whether it’s a custom-fitted shoe, a personalized piece of jewelry, or even bespoke medical implants, the ability to create products on demand—and tailored for the individual—could redefine consumer expectations.

This trend is also making its mark in the fashion industry, where designers are exploring 3D-printed garments and accessories. Imagine walking into a store and having an outfit designed just for you, based on your measurements and style preferences!

Sustainability

Sustainability is no longer just a buzzword; it’s a responsibility that many companies are embracing. The 3D printing industry has the potential to significantly reduce waste through its additive manufacturing process, where materials are only used when necessary, as opposed to traditional subtractive manufacturing, which can result in a lot of scrap.

Additionally, bio-based and recycled materials are gaining traction in the 3D printing community. Companies are beginning to manufacture filaments made from recycled plastics, and researchers are exploring plant-based materials for various applications. All of this aligns with the global push toward eco-friendly practices, and 3D printing is in a prime position to help lead the charge toward a greener future.

Decentralization of Manufacturing

The pandemic highlighted vulnerabilities in traditional supply chains, leading to a renewed interest in decentralized manufacturing. With 3D printing, companies can produce parts locally, reducing reliance on overseas manufacturing and lengthy shipping times. This decentralization means more resilient supply chains and greater responsiveness to customer needs.

Imagine a factory in your city that can print spare parts for machinery or even entire products on demand! This could significantly reduce lead times and costs, giving local businesses a crucial competitive edge.

Education and Skill Development

Lastly, as 3D printing continues to evolve, workforce development will become increasingly essential. Educational institutions are beginning to incorporate 3D printing technology into their curricula, helping students understand both the technical and creative aspects of this revolutionary process.

From high schools to universities, the push to teach 3D printing should result in a generation equipped to leverage this technology confidently, whether they’re pursuing careers in engineering, product design, or even art.

As we look toward the future of 3D printing, it’s clear that the trajectory is upward, with endless possibilities. Innovations in materials, AI, customization, sustainability, decentralization, and education are not just changing the landscape—they’re reshaping how we think about production and creation. The future is an open blueprint, and we can’t wait to see what gets designed next!